Preparation method of in-situ polymerized solid electrolyte

A solid-state electrolyte and in-situ polymerization technology, applied in the field of polymer materials, can solve problems such as the loss of active substances, and achieve the effects of slowing down capacity fading, improving safety, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

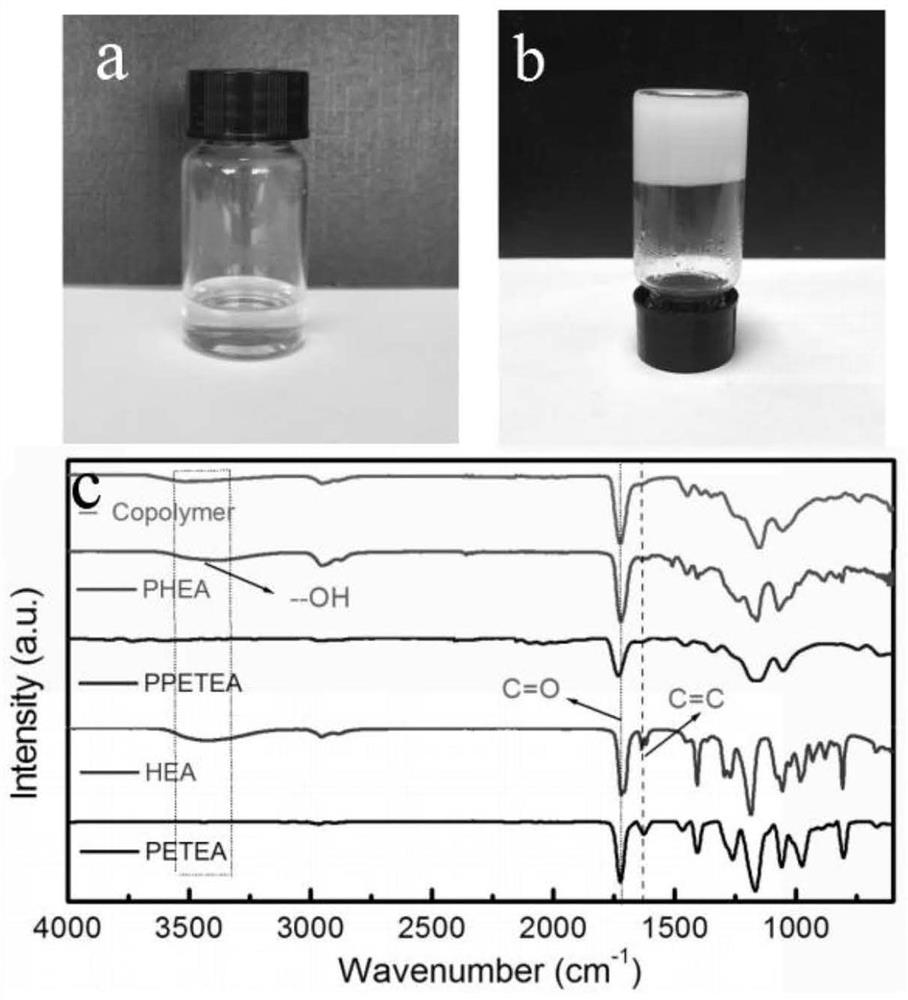

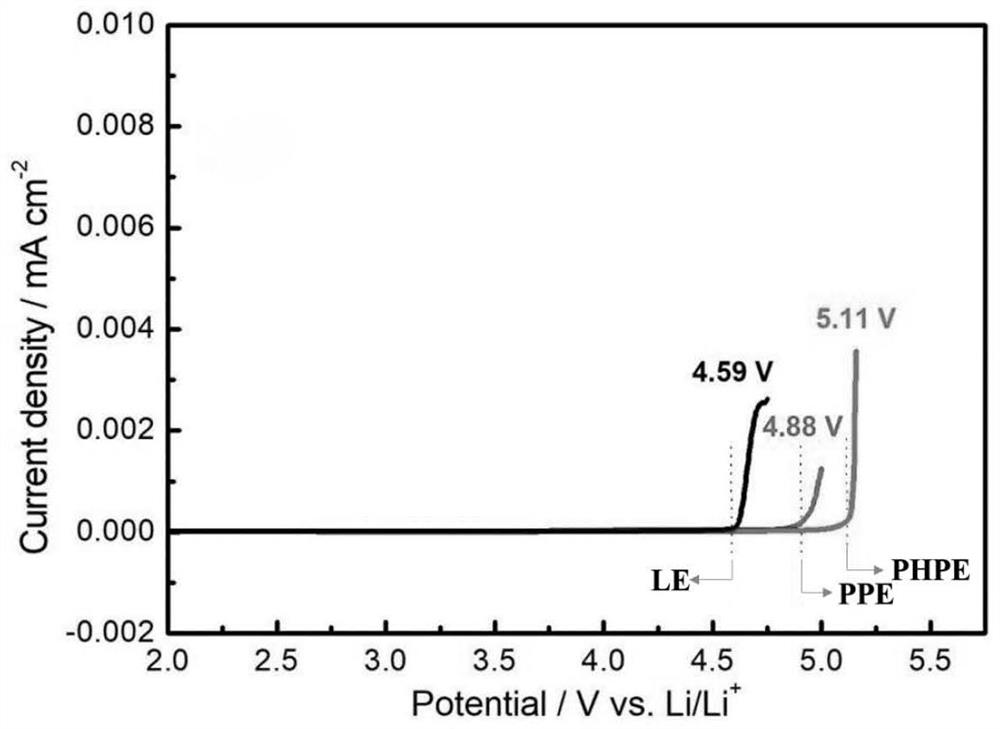

[0035] A method for preparing an in-situ polymerized solid electrolyte, comprising the following preparation steps:

[0036] (1) Preparation of electrolyte: uniformly dissolve lithium salt of bistrifluoromethanesulfonylimide in a mixture of ethylene glycol dimethyl ether and 1,3-dioxolane to prepare electrolyte; bistrifluoromethanesulfonyl imide The ratio of lithium methanesulfonylimide lithium salt to the mixed solution is 7.5g:25ml; the volume ratio of ethylene glycol dimethyl ether and 1,3-dioxolane in the mixed solution is 1:1.1;

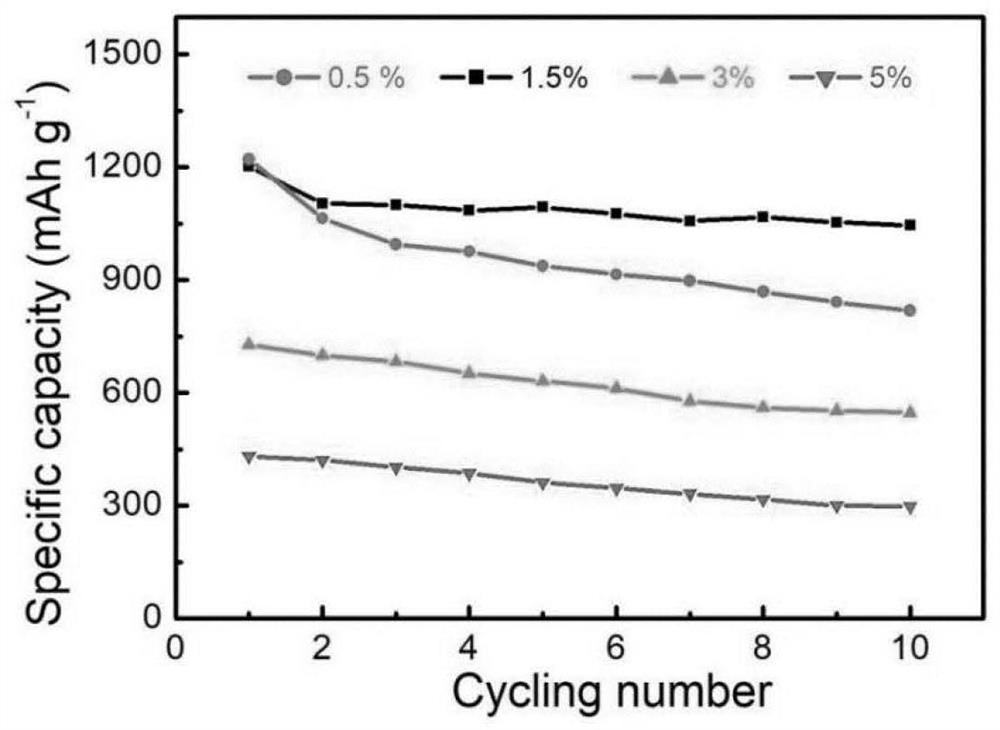

[0037] (2) Preparation of polymer slurry: Dissolve pentaerythritol tetraacrylate and 2-hydroxyethyl acrylate in the above electrolyte, then add azobisisobutyronitrile with 0.115 times the mass of pentaerythritol tetraacrylate, and stir at room temperature for 32 minutes to mix Uniform; the mass ratio of pentaerythritol tetraacrylate, 2-hydroxyethyl acrylate and electrolyte is 1.5:4:21;

[0038] (3) In-situ curing: Assemble the polymer slurry wi...

Embodiment 2

[0040] The difference from Example 1 is that a method for preparing an in-situ polymerized solid electrolyte includes the following preparation steps:

[0041] (1) Preparation of electrolyte: uniformly dissolve lithium salt of bistrifluoromethanesulfonylimide in a mixture of ethylene glycol dimethyl ether and 1,3-dioxolane to prepare electrolyte; bistrifluoromethanesulfonyl imide The ratio of lithium methanesulfonylimide lithium salt to the mixed solution is 7g:25ml; the volume ratio of ethylene glycol dimethyl ether and 1,3-dioxolane in the mixed solution is 1:1.2;

[0042] (2) Preparation of polymer slurry: dissolve pentaerythritol tetraacrylate and 2-hydroxyethyl acrylate in the above electrolyte solution, then add azobisisobutyronitrile with 0.1 times the mass of pentaerythritol tetraacrylate, and stir at room temperature for 30 minutes to mix Uniform; the mass ratio of pentaerythritol tetraacrylate, 2-hydroxyethyl acrylate and electrolyte is 1.5:1.5:22;

[0043] (3) In-s...

Embodiment 3

[0045] The difference from Example 1 is that a method for preparing an in-situ polymerized solid electrolyte includes the following preparation steps:

[0046] (1) Preparation of electrolyte: uniformly dissolve lithium salt of bistrifluoromethanesulfonylimide in a mixture of ethylene glycol dimethyl ether and 1,3-dioxolane to prepare electrolyte; bistrifluoromethanesulfonyl imide The ratio of lithium methanesulfonylimide lithium salt to the mixed solution is 8g:25ml; the volume ratio of ethylene glycol dimethyl ether and 1,3-dioxolane in the mixed solution is 1:1.2;

[0047] (2) Preparation of polymer slurry: Dissolve pentaerythritol tetraacrylate and 2-hydroxyethyl acrylate in the above electrolyte, then add azobisisobutyronitrile with 0.125 times the mass of pentaerythritol tetraacrylate, and stir at room temperature for 35 minutes to mix Uniform; the mass ratio of pentaerythritol tetraacrylate, 2-hydroxyethyl acrylate and electrolyte is 1.5:6:20;

[0048] (3) In-situ curin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com