Safety document and/or valuable document with scratch-proof covering layer

A technology for scratch resistance and document application in coating, transportation and packaging, printing, etc., which can solve the problems of high cost, embossing, and inability to maintain clarity, and achieve good scratch resistance and chemical resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0160] The preparation of these polycarbonates can be carried out in a known manner from diphenols, carbonic acid derivatives, optionally chain terminators and optionally branching agents. Details of polycarbonate preparation have been disclosed in numerous patent documents for about 40 years. By way of example only, Schnell, "Chemistry and Physics of Polycarbonate", Polymer Reviews, Vol. 9, Interscience Publishers, New York, London, Sydney 1964, referenced here by D. Freitag, U. Grigo, P.R. Müller, is mentioned here by reference , H.Nouvertne', BAYER AG, "Polycarbonate" in Encyclopedia of Polymer Science and Engineering, Vol. 11 2nd Edition, 1988, pp. 648-718 and last reference to Drs.U.Grigo, K.Kirchner and P.R.Müller" Polycarbonate" in Becker / Braun, Kunsts-ff-Handbuch, Vol. 3 / 1, Polycarbonate, Polyacetale, Polyester, Celluloseester, Carl Hanser Verlag Munich, Vienna 1992, Vol. 117-299.

[0161] Suitable diphenols may be, for example, dihydroxyaryl compounds of the general ...

Embodiment

[0198] Abbreviations and trade names used:

[0199] HDDA 1,6-Hexanediol diacrylate

[0200] PTTA pentaerythritol tetraacrylate

[0201] TMPTA Trimethylolpropane Triacrylate

[0202] HDI 1,6-Hexamethylene Diisocyanate

[0203] PTTA / HDI Reaction product of PTTA and HDI

[0204] Irgacure ? 184 1-Hydroxy-cyclohexyl phenyl ketone (photoinitiator from Ciba Specialty Chemicals)

[0205] BYK ? 306 Solution of polyether-modified polydimethylsiloxane in a xylene / monophenyl glycol mixture (mixing ratio 7 / 2) with a solids content of 12.5% by weight (wetting aid from BYK Additives & Instruments )

[0206] Components I) to IV) used:

[0207] Component I) HDDA

[0208] Component II) Ethoxylated TMPTA, weight average molecular weight M w is about 500g / mol (measured by GPC, using polystyrene as a standard)

[0209] Component III) PTTA (Examples 1-7 and Comparative Examples 1-4)

[0210] Component IV) TMPTA

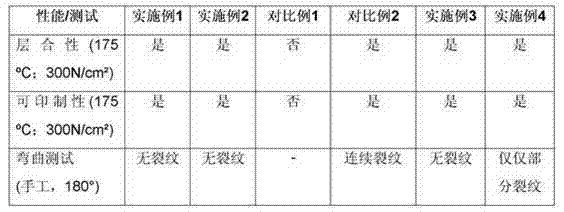

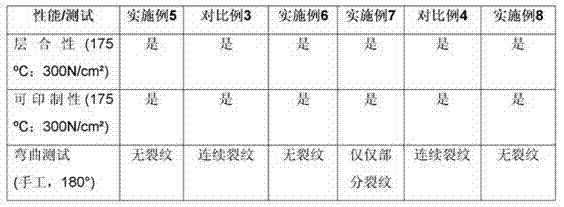

Embodiment 1-8() and comparative example 1-4

[0213] Prepare the paint composition:

[0214] According to the compositions described in Tables 1a and 1b, the parts by weight of HDDA were initially introduced into the mixing vessel, 7 parts by weight of the photoinitiator Irgacure ? 184. The mixture was stirred until the photoinitiator was dissolved. Thereafter, the photoinitiator solution was finely filtered (the pore width of the filter is 1 μm). Then the other monomers (TMPTA, ethoxylated TMPTA, PTTA or the reaction product of PTTA and HDI) and another 0.9 parts by weight of BYK ? 306 was added continuously with stirring and the mixture was then stirred for 15 minutes. The lacquer is again subjected to fine filtration (filter pore width 1 μm).

[0215] Table 1a

[0216] components Example 1 Example 2 Comparative example 1 Comparative example 2 Example 3 Example 4 HDDA 1) 19.5 48.8 73.8 11.9 25.3 24.2 TMPTA 1) 33.0 20.7 10.5 36.0 30.4 16.7 Ethoxylated TMPTA 1) 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com