Transmittance-increasing anti-haze coating material for optical BOPET film and preparation method thereof

An anti-fog coating and optical technology, applied in the direction of coating, etc., can solve the problems of adverse effects on the optical properties of thin films, hinder the development of optical films, etc., and achieve the effect of high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

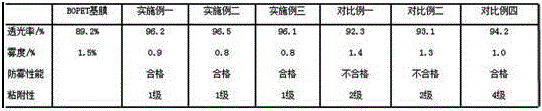

Examples

Embodiment 1

[0028] Weigh 3.00kg SiO 2 The nanoparticles are dispersed in water to form a silica dispersion with a concentration of 5 wt%. Add 0.05kg of silane coupling agent KH-570 to the silica dispersion system, start stirring at 70°C, and react for 30 minutes.

[0029] Under stirring, a mixture of 3.70 kg acrylic acid, 1.89 kg methacrylic acid, 0.58 kg ethylene glycol dimethacrylate, 0.58 kg trimethylolpropane triacrylate and 0.58 kg pentaerythritol tetraacrylate was added dropwise to the above system. At the same time, add dropwise an aqueous solution of 0.06 kg potassium persulfate dissolved in the solution, and control the dropping time at 1.5h.

[0030] After the dripping is completed, continue to stir, heat, keep warm (70±2°C) in a sealed reaction device and react for 8 hours, and cool the material to obtain the anti-reflection and anti-fog coating solution.

[0031] Dilute the coating solution to a solution with a concentration of 10 wt% with a diluent with a volume ratio of alcohol to...

Embodiment 2

[0034] The monomer ratio was changed, 2.64 kg of acrylic acid and 3.15 kg of methacrylic acid were added, except that other raw materials and reaction conditions were the same as in Example 1. An optical BOPET film with anti-reflection and anti-fog effect is obtained.

Embodiment 3

[0036] The monomer ratio was changed, 1.59 kg of acrylic acid and 4.41 kg of methacrylic acid were added, except that other raw materials and reaction conditions were the same as in Example 1, to obtain an optical BOPET film with antireflection and antifogging effects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com