Photocuring auxiliary direct-writing 3D printed silicone rubber ink, preparation method thereof and silicone rubber of three-dimensional structure

A 3D printing and three-dimensional structure technology, applied in the direction of additive processing, etc., can solve the problems of no PDMS forming and 3D printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method for photocuring assisted direct writing 3D printing silicone rubber ink described in the above scheme, comprising the following steps:

[0038] Mix PDMS silicone rubber, photoinitiator, trimethylolpropane triacrylate, ethoxylated pentaerythritol tetraacrylate and photosensitive silicone rubber to obtain photocuring-assisted direct writing 3D printing silicone rubber ink.

[0039] In the present invention, the order of mixing is preferably:

[0040] (1) photoinitiator, trimethylolpropane triacrylate and ethoxylated pentaerythritol tetraacrylate are mixed to obtain a photoinitiating system;

[0041] (2) Mixing the photoinitiating system and photosensitive silicone rubber to obtain a photosensitive system;

[0042] (3) Mixing the photosensitive system and the PDMS silicone rubber to obtain photocuring-assisted direct writing 3D printing silicone rubber ink.

[0043] In the present invention, the mixing in the step ...

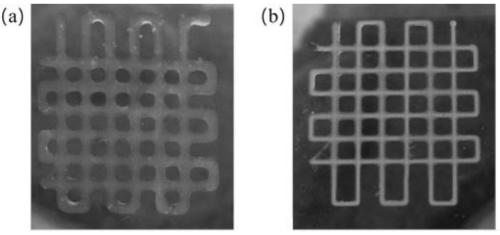

Embodiment 1

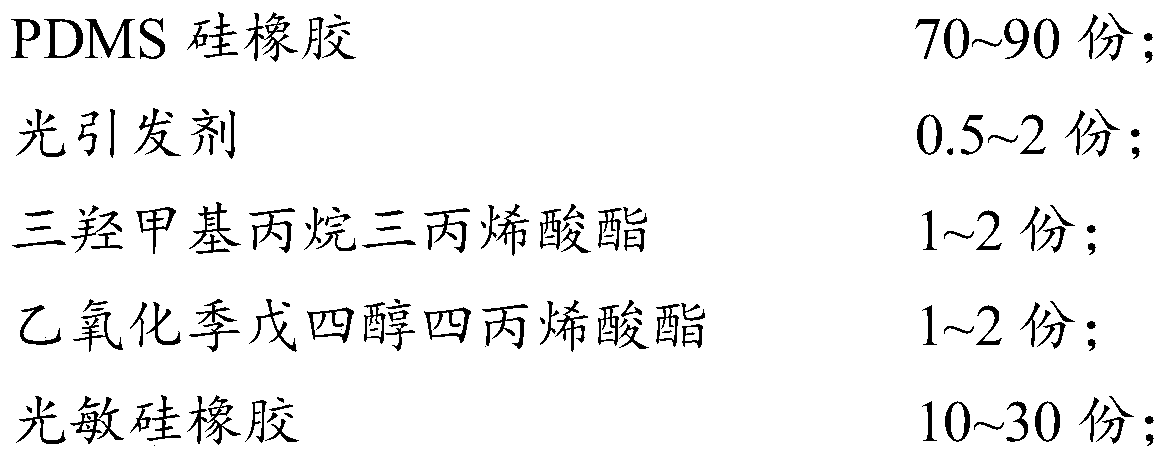

[0054] In parts by weight, the silicone rubber ink in the present embodiment consists of the following components:

[0055] 80 parts of Dow Corning SYLGARD184 PDMS silicone rubber, 0.5 parts of photoinitiator IRGACURE 819, 1.5 parts of trimethylolpropane triacrylate (TMPTA), 2 parts of ethoxylated pentaerythritol tetraacrylate (PPTTA), 16 parts of photosensitive silicone rubber, The viscosity of photosensitive silicone rubber is 2000-3000 cSt. The photosensitive silicone rubber is a copolymer of methyl acetoxypropyl methyl siloxane and dimethyl siloxane, purchased from Henan Geike Technology Co., Ltd.

[0056] Add IRGACURE 819 to the mixture of TMPTA and PPTTA and disperse in low temperature and avoid light until the solution is uniform and transparent to obtain a photoinitiating system; add the photoinitiating system to the photosensitive silicone rubber and stir mechanically until it is uniformly dispersed to obtain a photosensitive system; Mix A and B components of SYLGARD...

Embodiment 2

[0058] In parts by weight, the silicone rubber ink in the present embodiment consists of the following components:

[0059] 75 parts of Dow Corning SYLGARD184 PDMS silicone rubber, 1 part of photoinitiator IRGACURE 819, 2 parts of trimethylolpropane triacrylate (TMPTA), 2 parts of ethoxylated pentaerythritol tetraacrylate (PPTTA), 20 parts of photosensitive silicone rubber, The viscosity of photosensitive silicone rubber is 2000-3000 cSt. The photosensitive silicone rubber is a copolymer of methyl acetoxypropyl methyl siloxane and dimethyl siloxane, purchased from Henan Geike Technology Co., Ltd.

[0060] The preparation method of silicone rubber ink ink is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com