High-strength hydrophobic non-woven fabric and preparation method thereof

A hydrophobic, non-woven fabric technology, applied in the field of non-woven fabrics, can solve the problems of poor durability of hydrophobic fabrics, easy to fall off, affect the hydrophobicity of fabrics, etc., achieve good durability and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

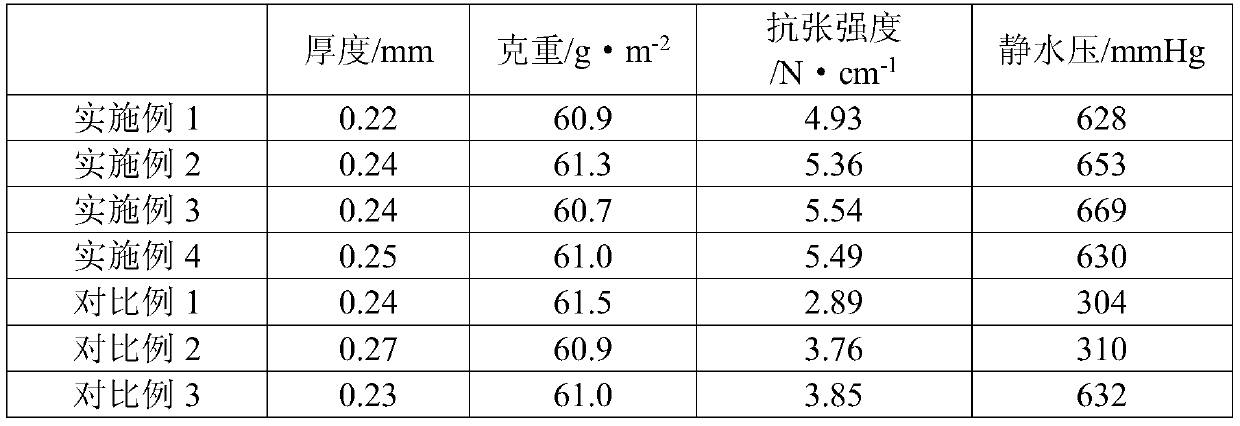

Examples

Embodiment 1

[0042] A kind of non-woven fabric is prepared by the following method:

[0043] (1) prepare tris-methyl acrylate-dipentaerythritol copolymer, concrete process is as follows:

[0044] (1.1) Addition reaction: Add 5.2g of trishydroxymethylaminomethane into 10mL of 50% methanol aqueous solution (50% methanol aqueous solution means the volume fraction of methanol is 50%), heat up to 30°C, stir and dissolve; dropwise add 5.2g A mixed solution of methyl acrylate and 10 mL of methanol was reacted at 30°C for 2 hours; after the reaction was completed, methanol, water and excess methyl acrylate were removed by vacuum to obtain the addition reaction product;

[0045] (1.2) Transesterification reaction: Add 1.3g of dipentaerythritol into 10mL of dimethyl sulfoxide, heat up to 90°C, stir to dissolve; add dropwise the addition reaction product obtained in step (1.1), heat up to 125°C, and react for 2h , and then reacted at 100°C and 0.08MPa for 2h; after the reaction was completed, dimeth...

Embodiment 2

[0055] A kind of non-woven fabric is prepared by the following method:

[0056] (1) prepare tris-methyl acrylate-dipentaerythritol copolymer, concrete process is as follows:

[0057] (1.1) Addition reaction: add 6.5g of trishydroxymethylaminomethane into 10mL of 50% aqueous methanol solution (50% aqueous methanol solution means the volume fraction of methanol is 50%), heat up to 33°C, stir and dissolve; add 7.8g of A mixed solution of methyl acrylate and 12 mL of methanol was reacted at 33°C for 2.5 hours; after the reaction was completed, methanol, water and excess methyl acrylate were removed by vacuum to obtain the addition reaction product;

[0058] (1.2) Transesterification reaction: Add 1.7g of dipentaerythritol into 10mL of dimethyl sulfoxide, heat up to 95°C, stir to dissolve; add dropwise the addition reaction product obtained in step (1.1), heat up to 127°C, and react 2.5 h, and then reacted at 105°C and 0.06MPa for 2h; after the reaction was completed, dimethyl sul...

Embodiment 3

[0068] A kind of non-woven fabric is prepared by the following method:

[0069] (1) prepare tris-methyl acrylate-dipentaerythritol copolymer, concrete process is as follows:

[0070] (1.1) Addition reaction: Add 7.2g of trishydroxymethylaminomethane into 15mL of 50% aqueous methanol solution (50% aqueous methanol solution means the volume fraction of methanol is 50%), heat up to 35°C, stir and dissolve; add 10.8g of A mixed solution of methyl acrylate and 15 mL of methanol was reacted at 35°C for 3 hours; after the reaction was completed, methanol, water and excess methyl acrylate were removed by vacuum to obtain an addition reaction product;

[0071] (1.2) Transesterification reaction: Add 2 g of dipentaerythritol into 10 mL of dimethyl sulfoxide, heat up to 100° C., stir to dissolve; add dropwise the addition reaction product obtained in step (1.1), heat up to 130° C., and react for 3 hours. Then react at 110°C and 0.05MPa for 2.5 hours; after the reaction is completed, dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com