A kind of modified polyester size and preparation method thereof

A technology for modifying polyester and sizing, applied in textiles and papermaking, fiber types, fiber processing, etc., can solve the problems of environmental pollution and use restrictions of PVA materials, achieve excellent sizing effect, clear openings, and reduce the rate of broken ends Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

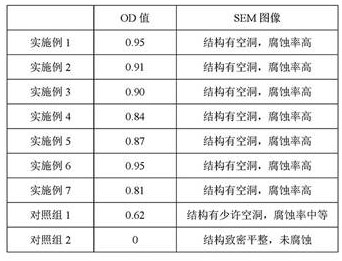

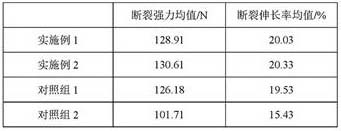

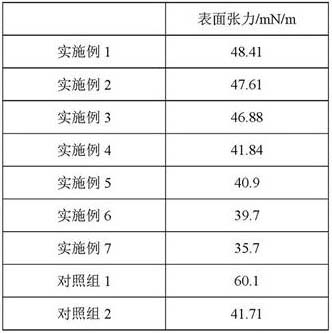

Examples

Embodiment 1

[0016] A modified polyester size, its preparation method is as follows:

[0017] (1) Preparation of polyester: under nitrogen, add 30 parts of citric acid and 15 parts of PEG-200, under stirring at 80rpm, react at 120°C for 60min, and cool the obtained reaction mixture to room temperature; Add glycerin and 40 parts of 2,2-bis(hydroxymethyl)propionic acid to the above reaction mixture, and react at 120°C for 6 hours under stirring at 80 rpm, add 10 parts of pure water during the reaction, and wait until the gel is formed Stop responding.

[0018] (2) The preparation steps of modified montmorillonite are as follows: (1) Mix 100 parts of montmorillonite with pure water to prepare a 5wt% suspension and heat it to 70°C; (2) Mix 30 parts with 50% ethanol Dissolve part of silicone oil, prepare 20% silicone oil solution, and add it dropwise to the above suspension, while stirring for 3 hours, slowly raise the temperature to 80°C; (3) After slowly heating the suspension to 90°C, conti...

Embodiment 2

[0023] A modified polyester size, its preparation method is as follows:

[0024] (1) Preparation of polyester: under nitrogen, add 30 parts of citric acid and 15 parts of PEG-200, under stirring at 80rpm, react at 120°C for 60min, and cool the obtained reaction mixture to room temperature; Add glycerin and 40 parts of 2,2-bis(hydroxymethyl)propionic acid to the above reaction mixture, and react at 120°C for 6 hours under stirring at 80 rpm, add 10 parts of pure water during the reaction, and wait until the gel is formed Stop responding.

[0025] (2) The preparation steps of modified montmorillonite are as follows: (1) mix 100 parts of montmorillonite with pure water to prepare a 5wt% suspension, and heat it to 70°C; (2) mix 30 parts with 50% ethanol Dissolve part of silicone oil, prepare 20% silicone oil solution, and add it dropwise to the above suspension, while stirring for 3 hours, slowly raise the temperature to 80°C; (3) After slowly heating the suspension to 90°C, cont...

Embodiment 3

[0030] (1) Preparation of polyester: under nitrogen, add 30 parts of citric acid and 15 parts of PEG-200, under stirring at 80rpm, react at 120°C for 60min, and cool the obtained reaction mixture to room temperature; Add glycerin and 40 parts of 2,2-bis(hydroxymethyl)propionic acid to the above reaction mixture, and react at 120°C for 6 hours under stirring at 80 rpm, add 10 parts of pure water during the reaction, and wait until the gel is formed Stop responding.

[0031] (2) The preparation steps of modified montmorillonite are as follows: (1) mix 100 parts of montmorillonite with pure water to prepare a 5wt% suspension, and heat it to 70°C; (2) mix 30 parts with 50% ethanol Dissolve part of silicone oil, prepare 20% silicone oil solution, and add it dropwise to the above suspension, while stirring for 3 hours, slowly raise the temperature to 80°C; (3) After slowly heating the suspension to 90°C, continue to stir for 3h , and then lower the temperature to room temperature w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com