Wrap loosening device for air jet loom

An air-jet loom and warp loosening device technology, applied in the field of solar energy, can solve the problems of poor opening, warp damage, opening amount and opening time cannot be closely unified, etc., and achieve the effect of clear opening and balanced tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

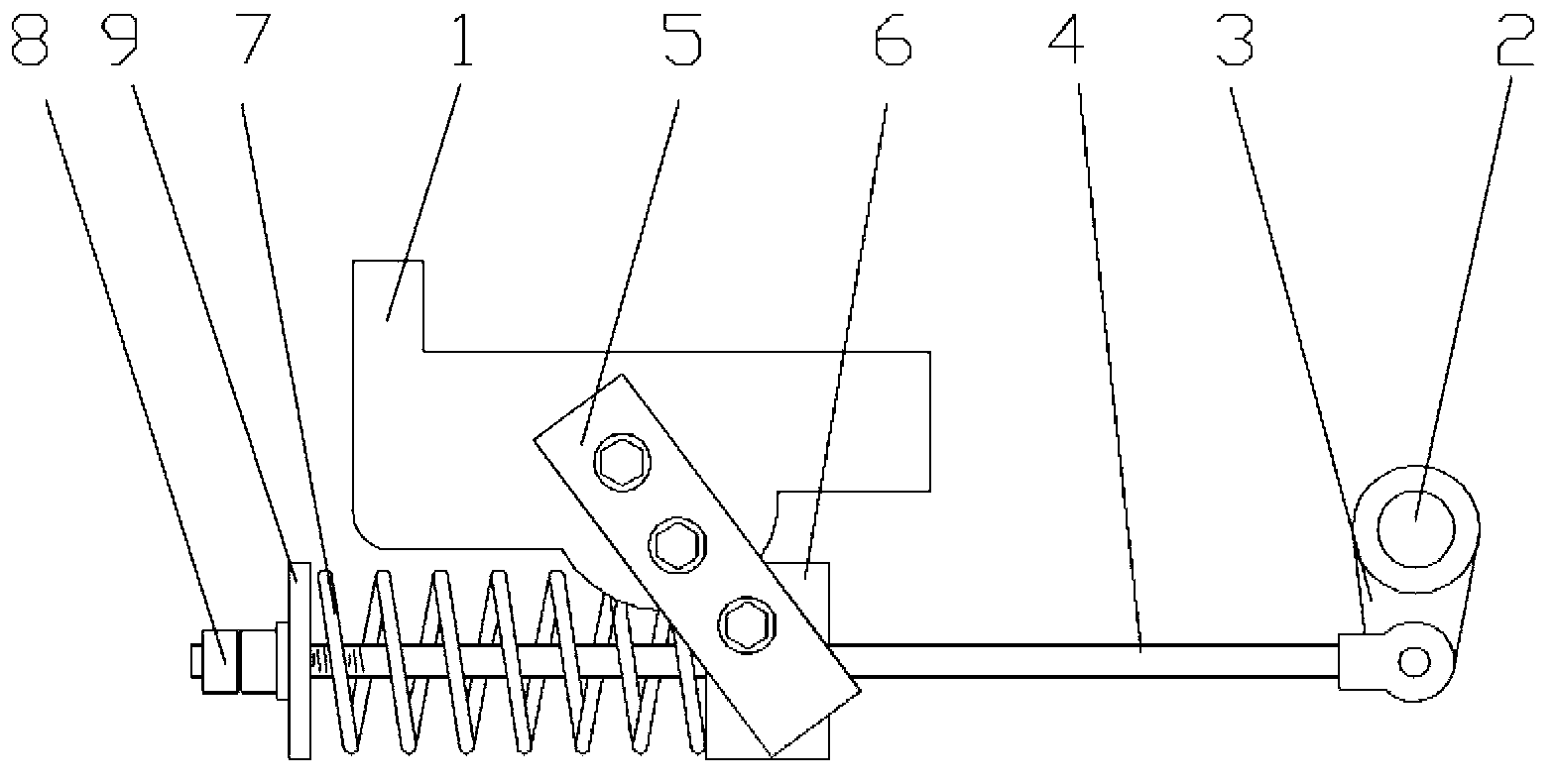

[0012] Example: see figure 1 As shown, a warp loosening device of an air-jet loom comprises an air-jet loom frame 1, a warp loosening shaft 2 of the air-jet loom, a crank 3 is hinged on the warp loosening shaft 2 of the air-jet loom, and a warp loosening bar 4 is hinged on the crank 3 Above, a support 5 is fixed on the frame 1 of the air-jet loom, and a guide block 6 is fixed on the support 5. The warp loosening rod 4 is inserted and sleeved on the guide block 6. One end of the compression spring 7 acts on the loosening warp rod 4 and the other end acts on it. Force on the guide block 6.

[0013] A nut 8 is screwed on the warp loosening rod 4 , and a stopper 9 is inserted and sleeved on the warp loosening rod 4 .

[0014] Working principle: in the prior art, the active force of the rocker arm is used to generate the power of warp loosening, which belongs to the positive warp loosening method. The present invention relies on the force of the loose warp beam 2 of the air-jet l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com