Manufacturing method of foldable paper-based micro supercapacitor

A supercapacitor and miniature technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of single current and voltage output form, easy to break, and unclear electrodes, so as to ensure stability, low cost, The effect of not easy to break the circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038](1) Add the mixture of 9g graphite powder and 9g sodium nitrate into 240mL concentrated sulfuric acid (mass fraction 98%), stir for 30min, then slowly add 27g potassium permanganate, continue stirring for 30min, then raise the temperature to 40°C and keep it warm 2h, then raise the temperature to 50°C and keep it warm for 1h, then slowly add 400mL of deionized water and raise the temperature to 90°C, keep it at 90°C for 20min, then add 1000mL of water to cool and stand still, filter to leave the solute, first use mass 50% dilute hydrochloric acid for suction filtration and washing, then further suction filtration and washing with 10% dilute hydrochloric acid for mass fraction, and finally put into a dialysis bag and dialyze to neutrality to obtain a graphene oxide solution with a concentration of 7 mg / mL;

[0039] (2) Add 15mL graphene oxide solution and 0.5mL absolute ethanol into a polytetrafluoroethylene container, then place the bottom of the polytetrafluoroethylene c...

Embodiment 2

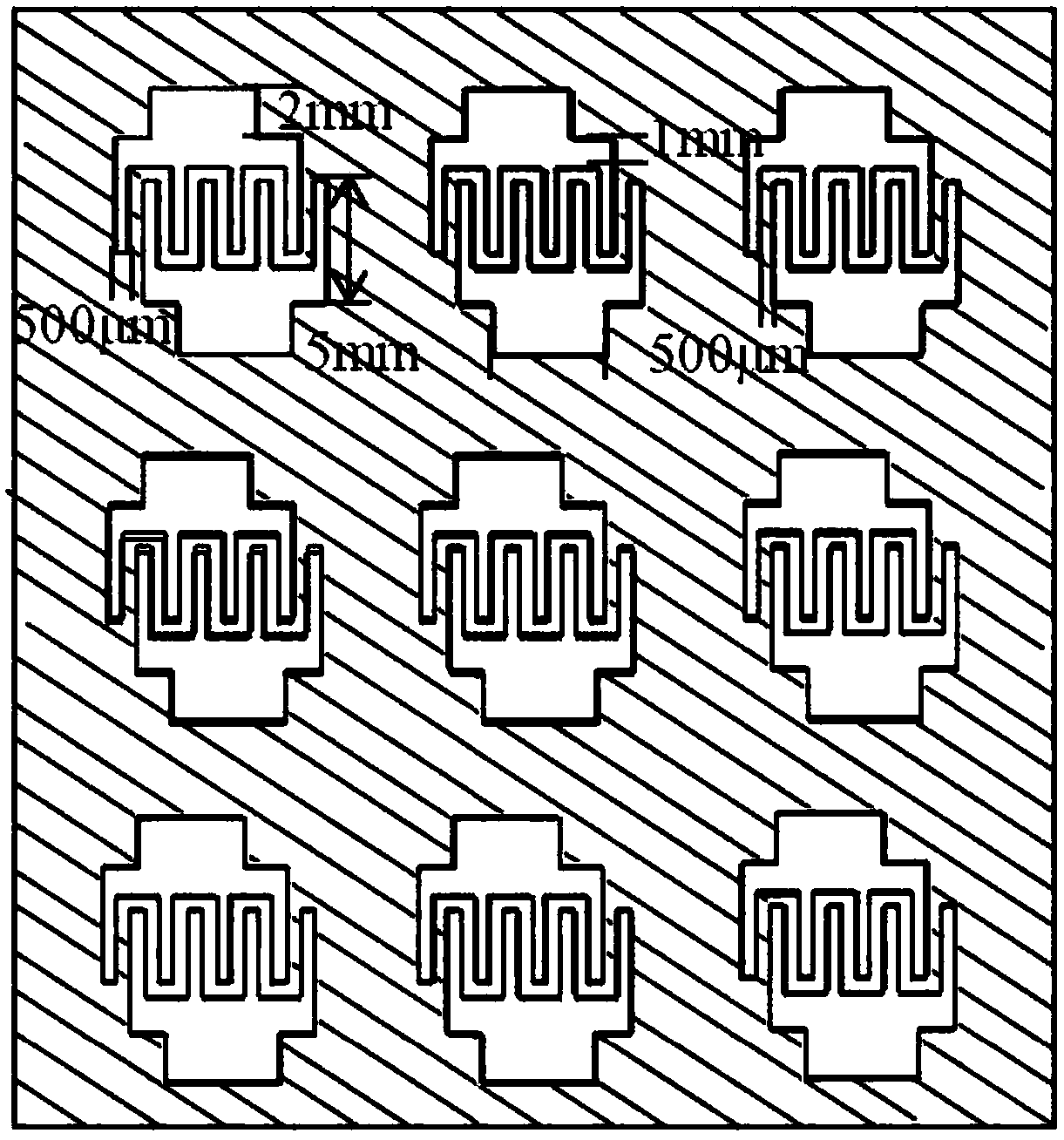

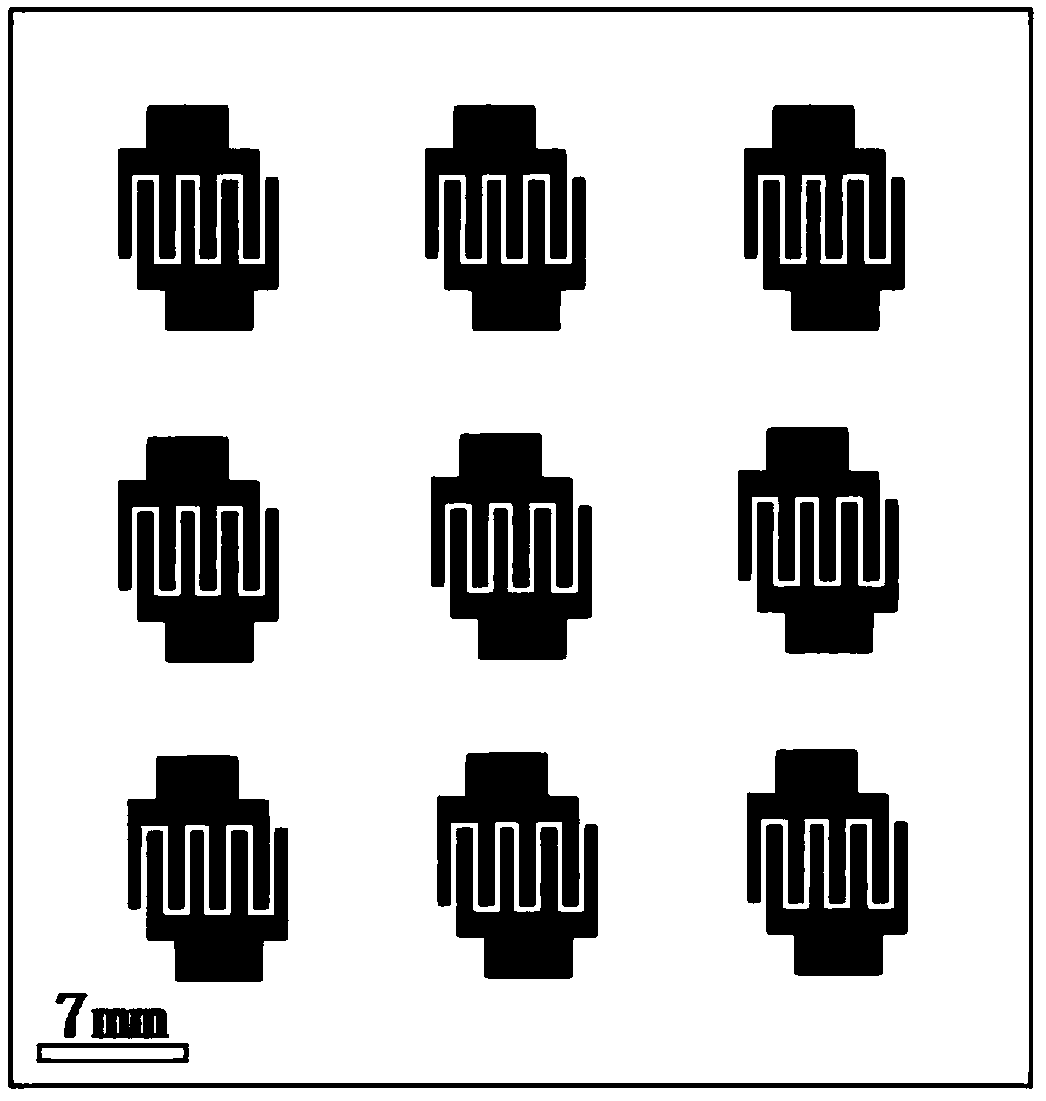

[0053] (1) Use a laser to etch the copper foil to obtain nine copper templates based on interdigital electrode patterns; wherein, the thickness of the copper template is 20 μm, and each electrode pattern based on interdigital structure is formed by two interdigital structures. The electrodes are arranged crosswise, the number of fingers of each finger electrode is 6, the width of each finger is 300μm, and the length of each finger is 4mm. In the electrode pattern based on the finger structure, two adjacent fingers The finger spacing width is 300 μm, and the total area of each electrode pattern based on the interdigital structure is 0.21 cm 2 ;

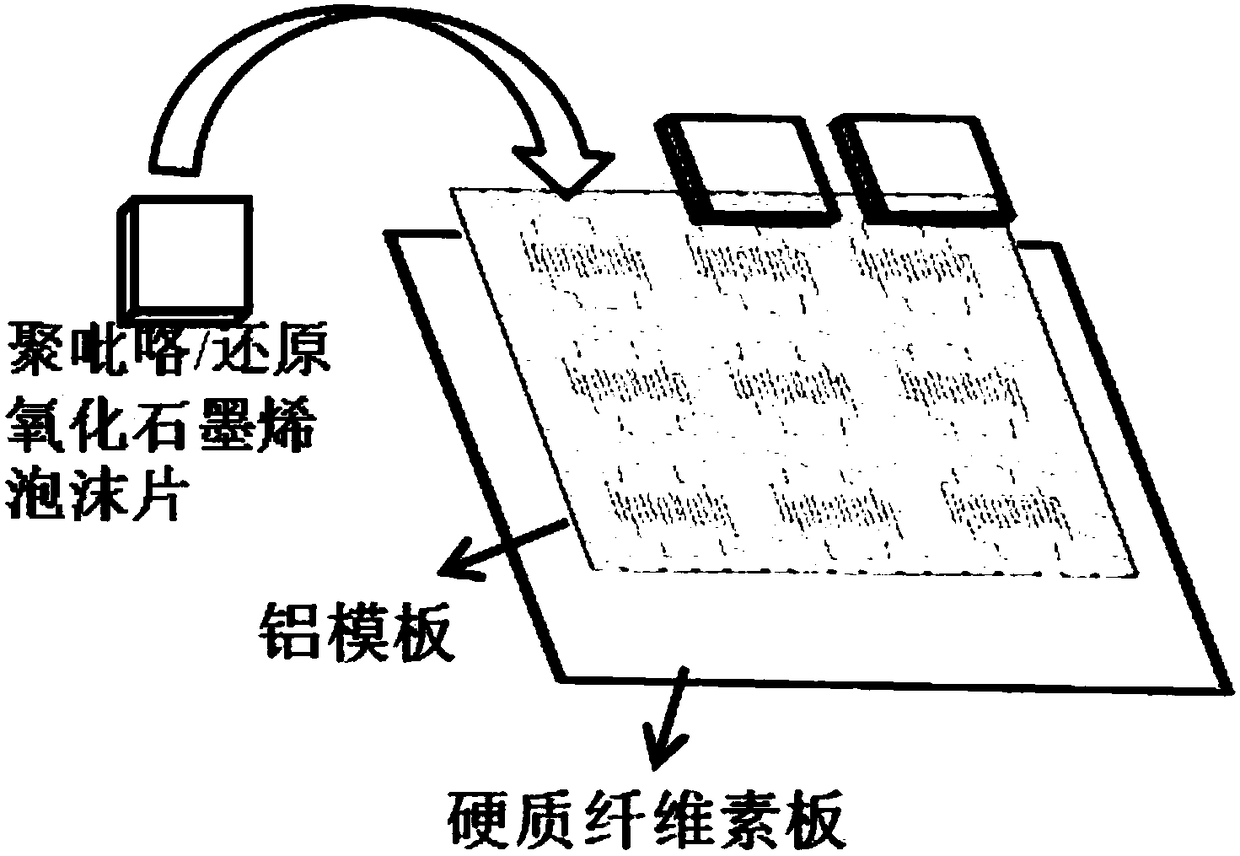

[0054] (2) cut the reduced graphene oxide foam obtained in embodiment 1 step (3) into a sheet with a thickness of 1.5mm with a cutter; the copper template is placed on a hard cellulose cardboard, and then the reduced graphene oxide The foam sheet is placed on the copper template and completely covers the electrode pattern based on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com