Additive and solvent of lithium secondary battery electrolyte

An electrolyte additive and lithium secondary battery technology, which is applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low flash point and boiling point, limited application, low oxidation potential, etc., achieve small migration resistance and improve electrical conductivity rate, moving fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

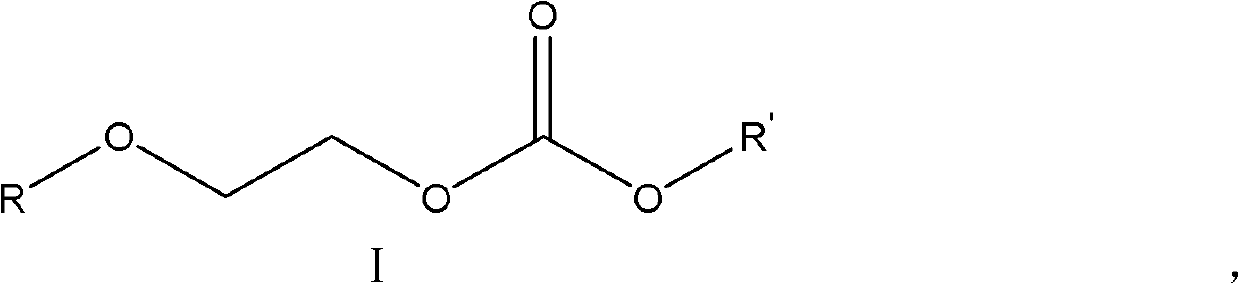

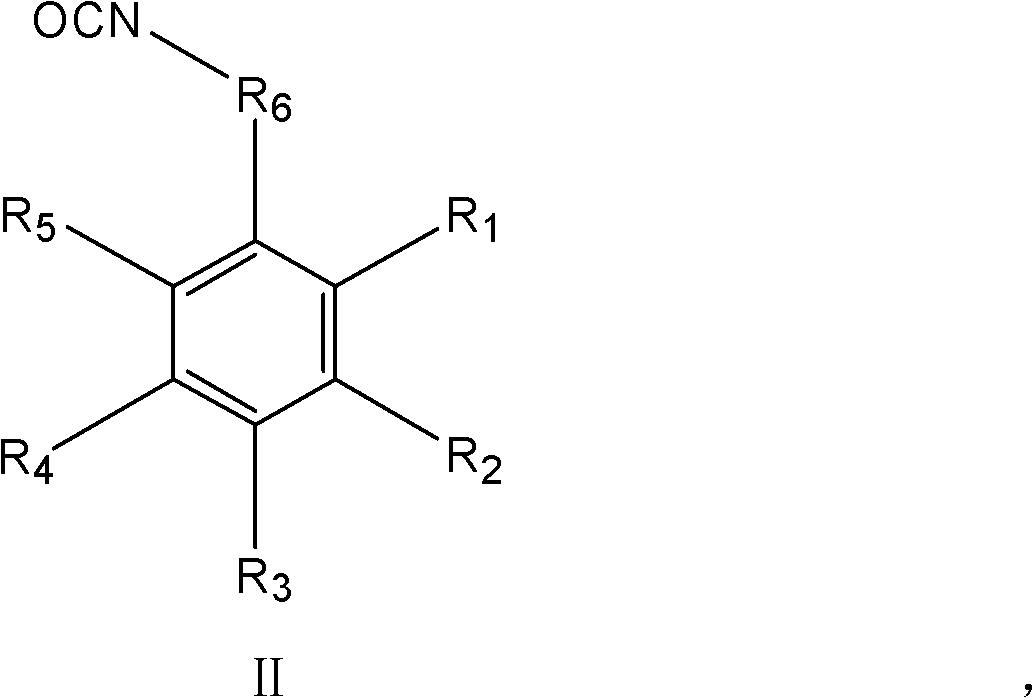

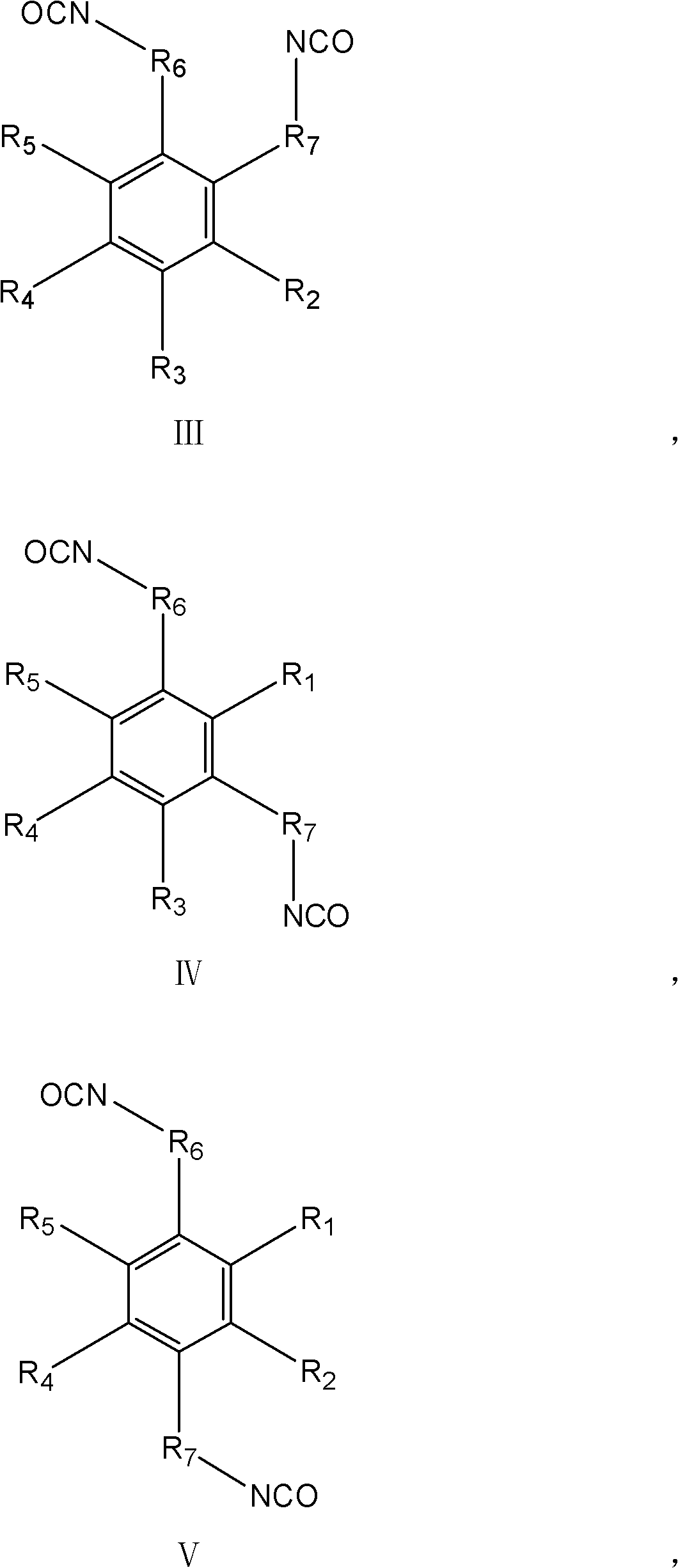

Method used

Image

Examples

Embodiment 1

[0061] Taking the mass of solvent and additive as 100%, take by weight respectively 20% ethylene carbonate (EC), 50% ethyl methyl carbonate (EMC) and 30% additive A and mix to obtain mixed solution, Then add lithium salt LiClO 4 , fully stirred evenly until the solution was clear without precipitation, and the electrolyte sample was obtained; among them, LiClO 4 The concentration of the substance is 1mol / L. Electrolyte samples were prepared in an argon-filled glove box. The structural formula of additive A is shown in formula A,

[0062]

[0063] Put the electrolyte sample into a platinum conductivity electrode (Shanghai Leici), and use a CHI604D electrochemical workstation (Shanghai Chenhua) to test it at -35°C (low temperature), 20°C (normal temperature) and 80°C (high temperature) respectively. ) under the AC impedance test, the corresponding conductivity is obtained by the ratio of the conductivity constant to the data on the x-axis at the lowest point read in the AC...

Embodiment 2

[0066] Based on the mass of the solvent and additives as 100%, weigh 20% ethylene carbonate, 50% ethyl methyl carbonate and 30% additive B and mix them to obtain a mixed solution, and then add lithium salt LiClO 4 , fully stirred evenly until the solution was clear without precipitation, and the electrolyte sample was obtained; among them, LiClO 4 The concentration of the substance is 1mol / L. Electrolyte samples were prepared in an argon-filled glove box. The structural formula of additive B is shown in formula B,

[0067]

[0068] Put the electrolyte sample into the platinum conductivity electrode (Shanghai Leici), and use the CHI604D electrochemical workstation (Shanghai Chenhua) to conduct AC impedance tests at -35°C, 20°C and 80°C respectively. The ratio of the rate constant to the data on the x-axis at the lowest point read in the AC impedance spectrum is used to obtain the corresponding conductivity, and the results are shown in Table 1.

[0069] A button-type half...

Embodiment 3

[0071] Based on the mass of the solvent and the additive as 100%, weigh 20% ethylene carbonate, 50% ethyl methyl carbonate and 30% additive C and mix them to obtain a mixed solution, then add lithium salt LiClO 4 , fully stirred evenly until the solution was clear without precipitation, and the electrolyte sample was obtained; among them, LiClO 4 The concentration of the substance is 1mol / L. Electrolyte samples were prepared in an argon-filled glove box. The structural formula of additive C is shown in formula C,

[0072]

[0073] Put the electrolyte sample into the platinum conductivity electrode (Shanghai Leici), and use the CHI604D electrochemical workstation (Shanghai Chenhua) to conduct AC impedance tests at -35°C, 20°C and 80°C respectively. The ratio of the rate constant to the data on the x-axis at the lowest point read in the AC impedance spectrum is used to obtain the corresponding conductivity, and the results are shown in Table 1.

[0074] A button-type half-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com