Method for preparing grapheme/carbon composite material

A carbon composite material and graphene technology, applied in the field of graphene, can solve the problems of difficult to obtain a composite material with a uniform structure, easy agglomeration of graphene, affecting the electrochemical performance of the material, etc., achieve good capacity performance and cycle performance, and prevent agglomeration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of graphene / carbon composite material, comprises the following steps:

[0026] A) Mix and react aniline monomer, oxidant and graphene oxide in liquid crystal state to obtain a graphene oxide / polyaniline composite;

[0027] B) Mix the graphene oxide / polyaniline composite obtained in step A) with an activator and react to obtain a graphene / carbon composite material.

[0028] The present invention uses aniline monomer and graphene oxide in a liquid crystal state as raw materials, fully mixes them, and generates polyaniline between the graphene oxide layers, which can effectively prevent graphene from agglomerating during the activation process, and at the same time, the activation process can The polyaniline attached to the graphene surface forms a porous carbon material, so that the prepared graphene / carbon composite material has good capacity performance and cycle performance.

[0029] The present invention firstly mix...

Embodiment 1

[0041] Use the Hummer method to prepare graphene oxide solution, wash it repeatedly with deionized water, and use barium chloride solution to detect until no white precipitate appears, then treat the graphene oxide aqueous solution in a centrifuge at 5000~10000r / min for 30min, then you can A liquid crystal graphene oxide sol with a concentration range of 0.1 mg / mL-15 mg / mL was obtained.

Embodiment 2

[0043] Mix 1g of aniline monomer with 100mL of graphene oxide hydrosol with a concentration of 1mg / mL, fully dissolve 2.33g of ammonium persulfate in 20mL of deionized water, and then slowly add it dropwise to the mixed sol of aniline monomer and graphene oxide , then react in a hydrothermal tank at 200°C for 8h, wash the reaction product with deionized water and ethanol to obtain a graphene oxide / polyaniline composite product; then mix 1g of the obtained graphene oxide / polyaniline composite with 1g of hydrogen Potassium oxide was mixed and fully ground, then placed in a tube furnace, reacted at 500°C for 48 hours under the protection of nitrogen, and the product was washed with deionized water and dried to obtain a graphene / carbon composite material.

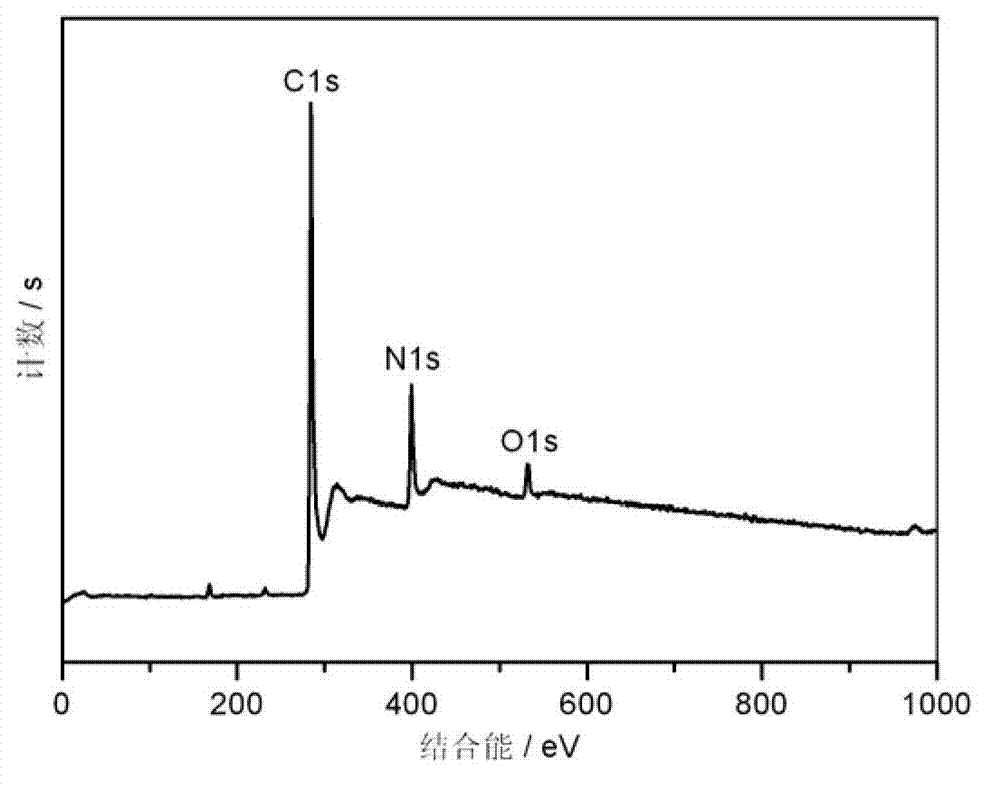

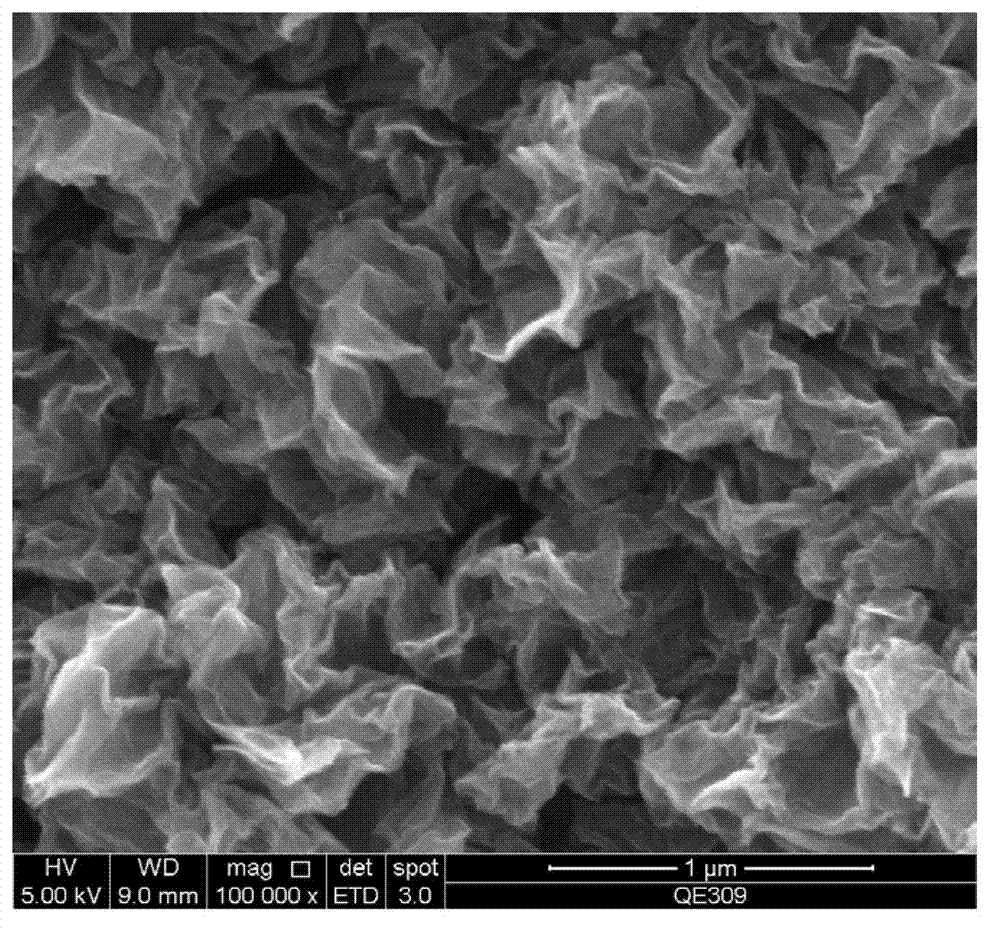

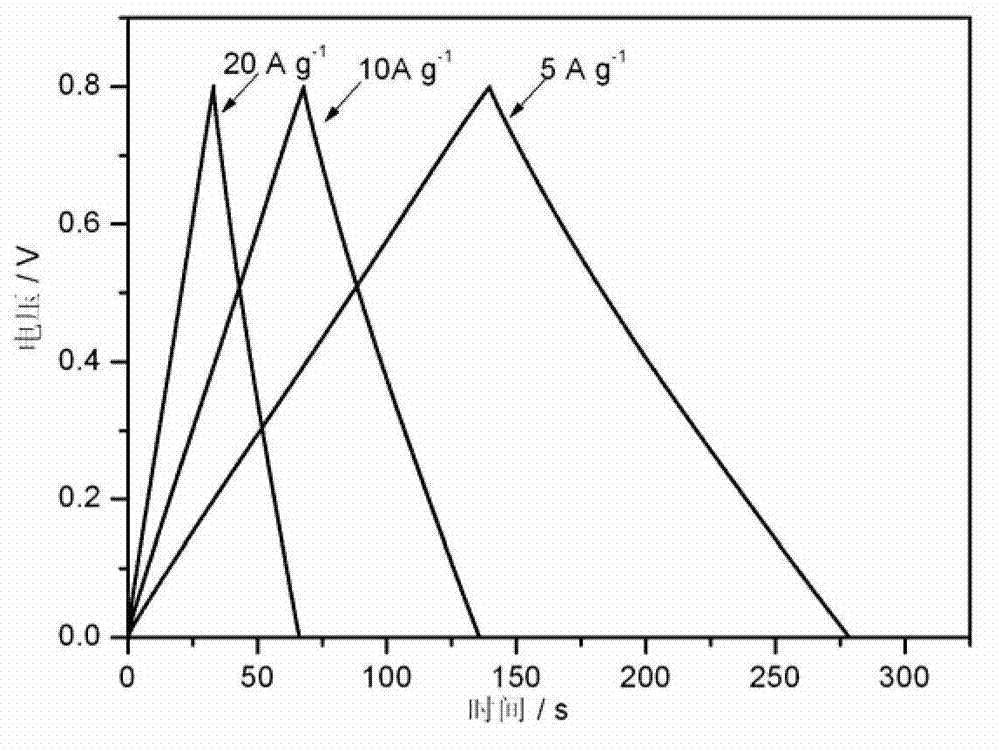

[0044] Carry out X-ray photoelectron scanning to the graphene / carbon composite material that prepares, the result sees figure 1 , figure 1 It is the X-ray photoelectron energy spectrogram of the graphene / carbon composite mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com