Integrated self-charging micro supercapacitor device and preparation thereof

A supercapacitor and self-charging technology, applied in the field of energy storage devices, can solve problems such as affecting the conductivity of the device, unable to drive other electrical devices, easy to corrode, etc., to reduce internal resistance and heat loss, and ensure integrity and connectivity. , the preparation method is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

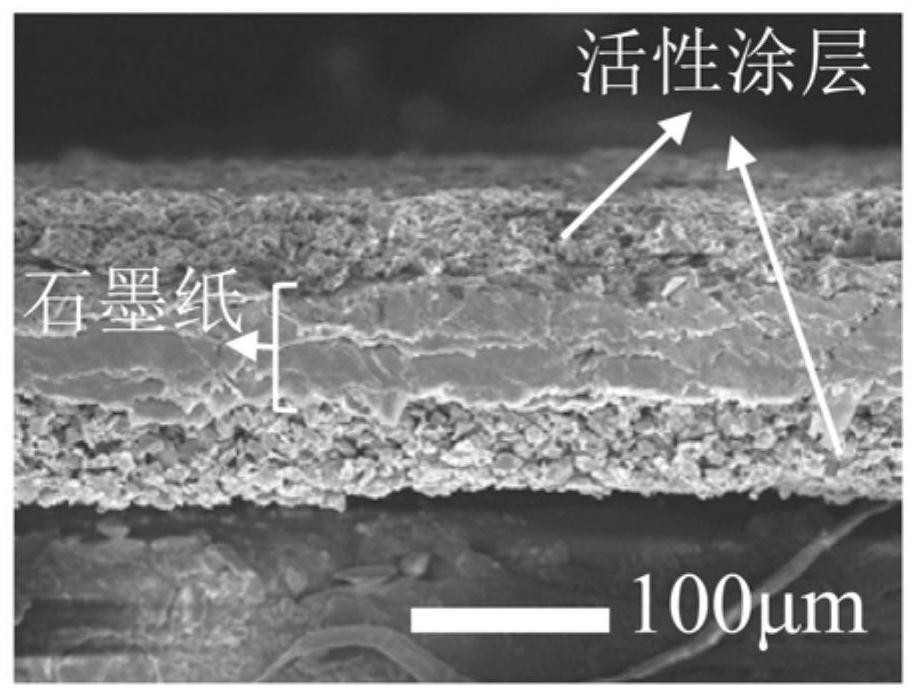

[0046] (1) Mix 0.8 g of activated carbon, 0.1 g of PVDF, 0.1 g of Ketjen black, and 4 mL of NMP, and grind the mixture in a mortar for 20 min to obtain a uniform viscous slurry; then, coat the slurry on a surface with a size of 3.7 cm × 4cm × 50μm on one side of the graphite paper, and then put the graphite paper coated with the slurry in a vacuum oven at 60°C for 12 hours to obtain an active coating on one side of the graphite paper, and the active coating is on The loading capacity on graphite paper is 3.194±0.2mg / cm 2 ;

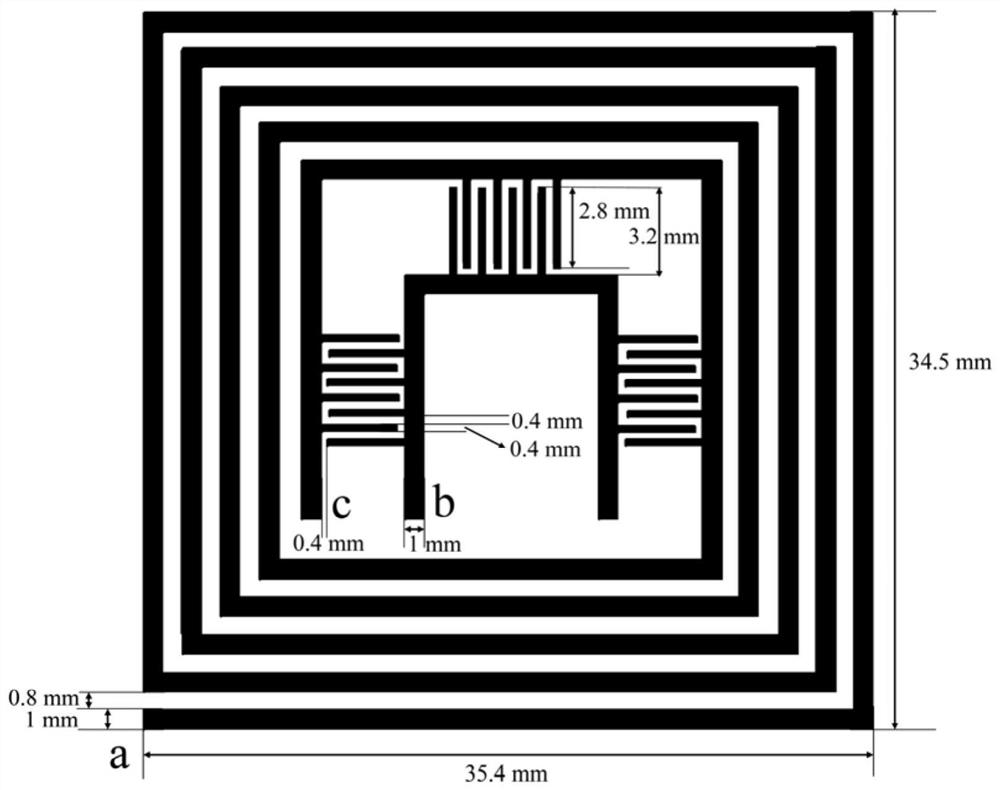

[0047] (2) Use a laser with a power of 20W to etch the graphite paper coated with an active coating on the surface, etch the integrated outer coil, electrode and inner coil on the graphite paper, and three parallel electrodes are located on the outer coil. Between the coil and the inner coil, and the fingers in each electrode are alternately connected with the outer coil and the inner coil, such as figure 1 shown;

[0048] The outer coil is a rectangula...

Embodiment 2

[0054] (1) Mix 0.8 g of activated carbon, 0.1 g of PVDF, 0.1 g of Ketjen black, and 4 mL of NMP, and grind the mixture in a mortar for 20 min to obtain a uniform viscous slurry; then, coat the slurry on a surface with a size of 3.7 cm × 4cm × 50μm on both sides of graphite paper, and then put the graphite paper coated with slurry in a vacuum oven at 60 ° C for 12 hours to obtain active coatings on both sides of the graphite paper, and the active coating is on The total loading on graphite paper is 23.72 mg / cm 2 ;

[0055] (2) Use a laser with a power of 20W to etch the graphite paper coated with an active coating on the surface, etch the integrated outer coil, electrode and inner coil on the graphite paper, and three parallel electrodes are located on the outer coil. Between the coil and the inner coil, and the fingers in each electrode are alternately connected with the outer coil and the inner coil;

[0056] The outer coil is a rectangular coil arranged in a helical shape....

Embodiment 3

[0061] (1) Mix 0.8 g of activated carbon, 0.1 g of PVDF, 0.1 g of Ketjen black, and 4 mL of NMP, and grind the mixture in a mortar for 20 min to obtain a uniform viscous slurry; then, coat the slurry on a surface with a size of 3.7 cm × 4cm × 50μm on both sides of graphite paper, and then put the graphite paper coated with slurry in a vacuum oven at 60 ° C for 12 hours to obtain active coatings on both sides of the graphite paper, and the active coating is on The total loading on graphite paper is 23.72 mg / cm 2 ;

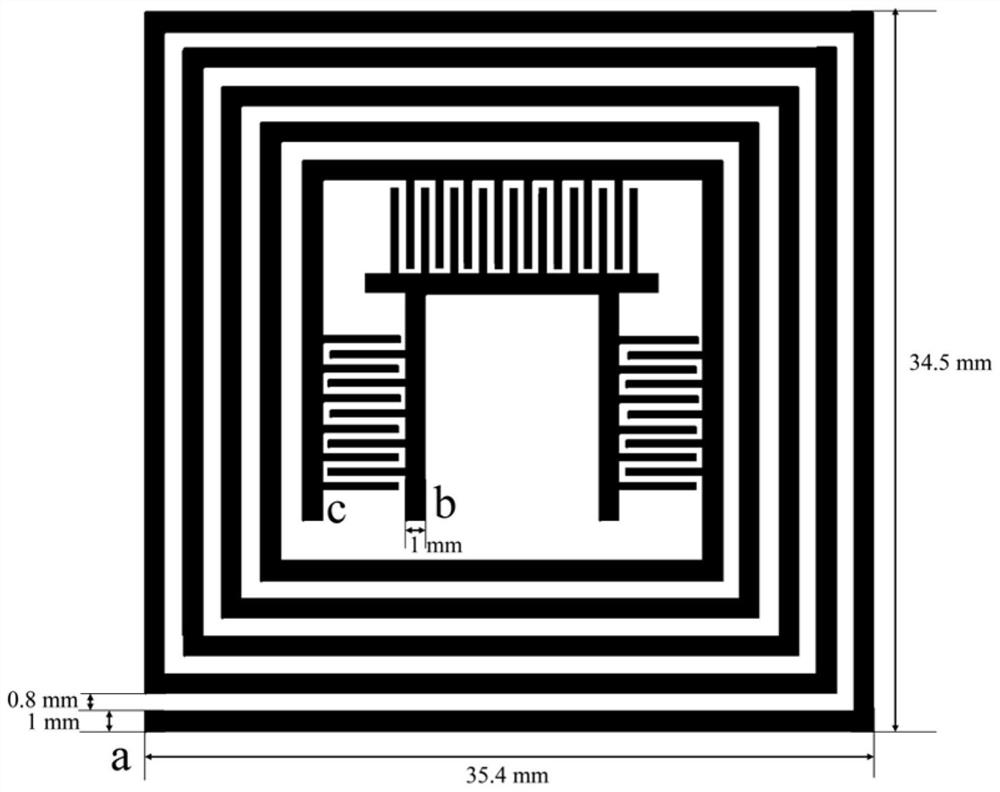

[0062] (2) Use a laser with a power of 20W to etch the graphite paper coated with an active coating on the surface, etch the integrated outer coil, electrode and inner coil on the graphite paper, and three parallel electrodes are located on the outer coil. Between the coil and the inner coil, and the fingers in each electrode are alternately connected with the outer coil and the inner coil, such as figure 2 shown;

[0063] The outer coil is a rectangular coil ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com