Copper wire material for bonding wire and method for producing copper wire material for bonding wire

A technology for bonding wires and wires, which is used in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of reduced productivity, wire breakage, insufficient wire extensibility, etc. Line and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

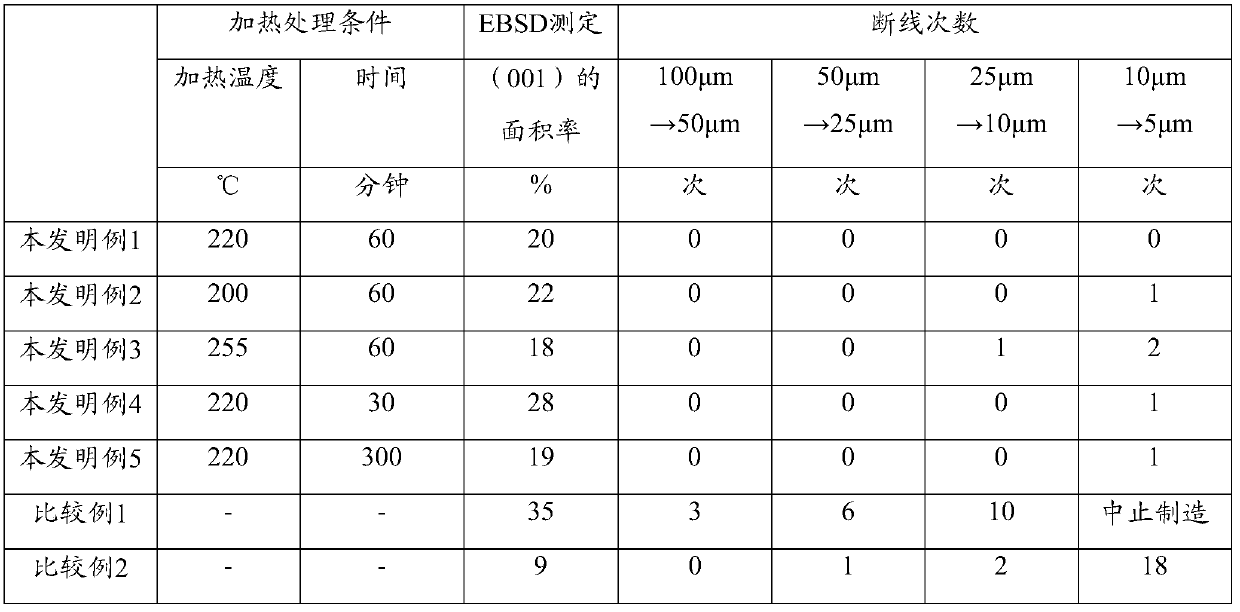

[0055] Hereinafter, the results of confirmation experiments conducted to confirm the effectiveness of the present invention will be described.

[0056] (Examples 1 to 5 of the present invention)

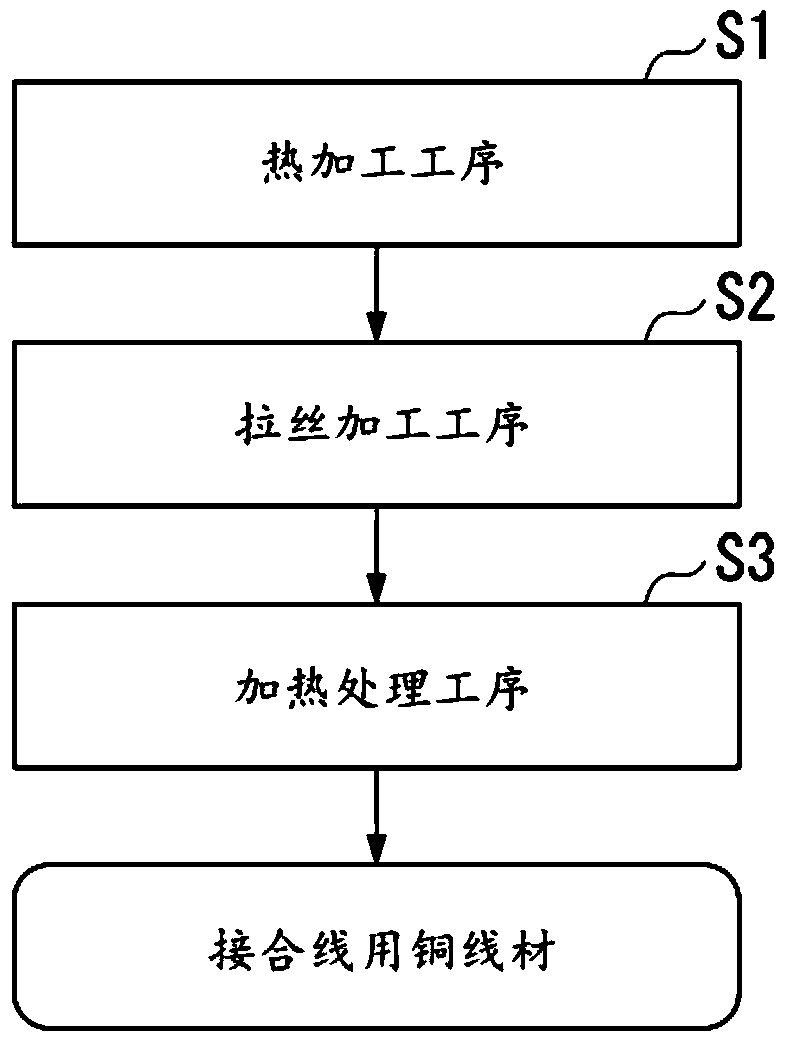

[0057] First, a steel billet with a diameter of 250 mm and a length of 700 mm made of high-purity copper having a purity of 99.9999% by mass or higher was prepared. This billet was heated to 800° C., and subjected to hot extrusion processing to produce a wire rod with a diameter of 8 mm.

[0058] Next, the wire rod with a diameter of 8 mm was subjected to wire drawing including cold peeling and wire drawing until the diameter reached 1 mm. In addition, in this wire drawing process, the reduction of area was set to 98%, and the number of passes was set to 15 times.

[0059] Next, the drawn wire rod was charged into a batch annealing furnace, and heat-treated at the heating temperature and heating time shown in Table 1. In addition, the atmosphere of the batch type annealing furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com