Wiring method and manufacturing method of capacitive touch screen

A technology of a capacitive touch screen and a manufacturing method, which is applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problem of reducing the quality of touch screen products, high wire resistance of conductive films of wires, and color difference of two layers of conductive films. and other problems, to achieve the effect of good consistency of line resistance value, improve yield rate, and avoid chromatic aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

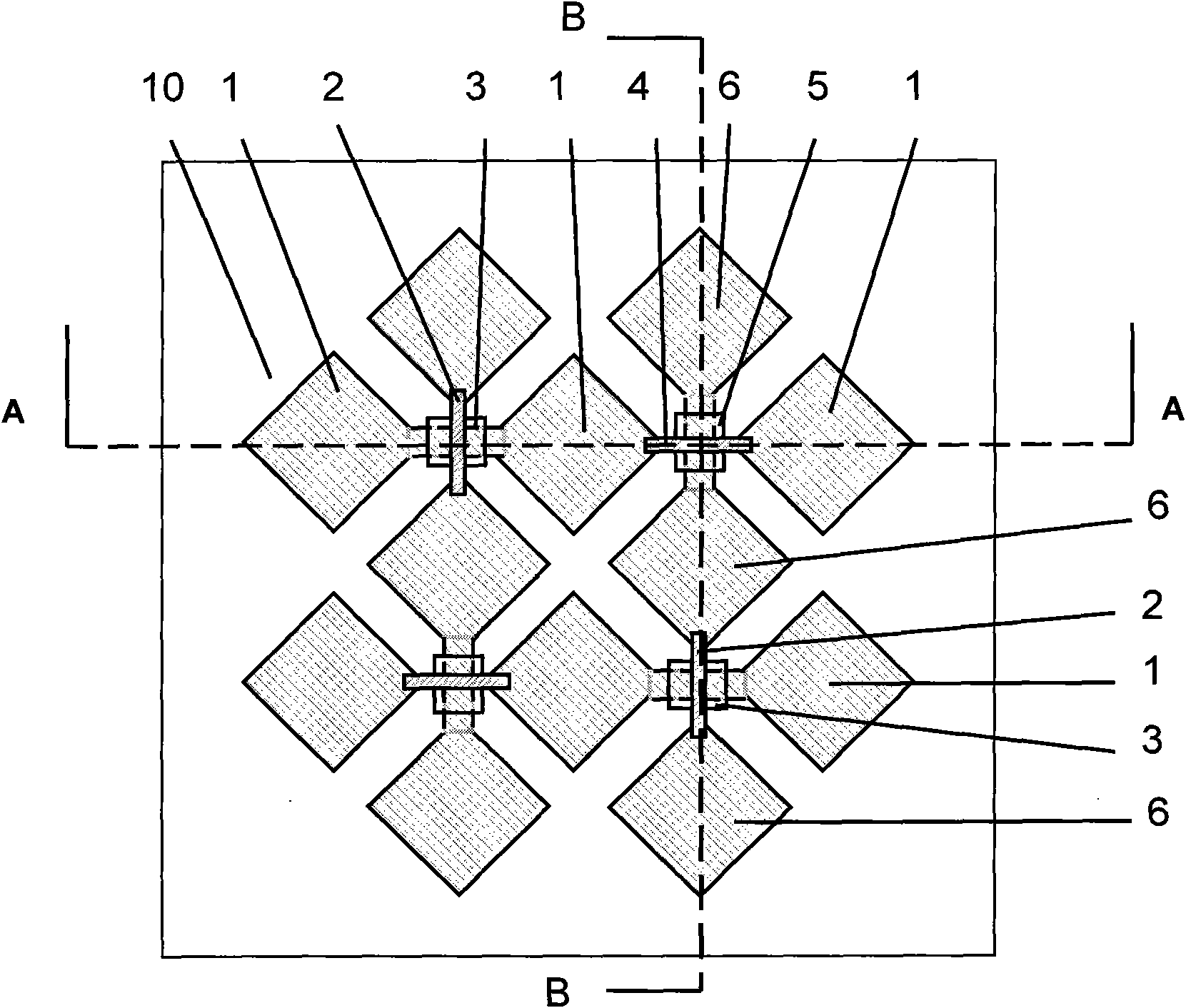

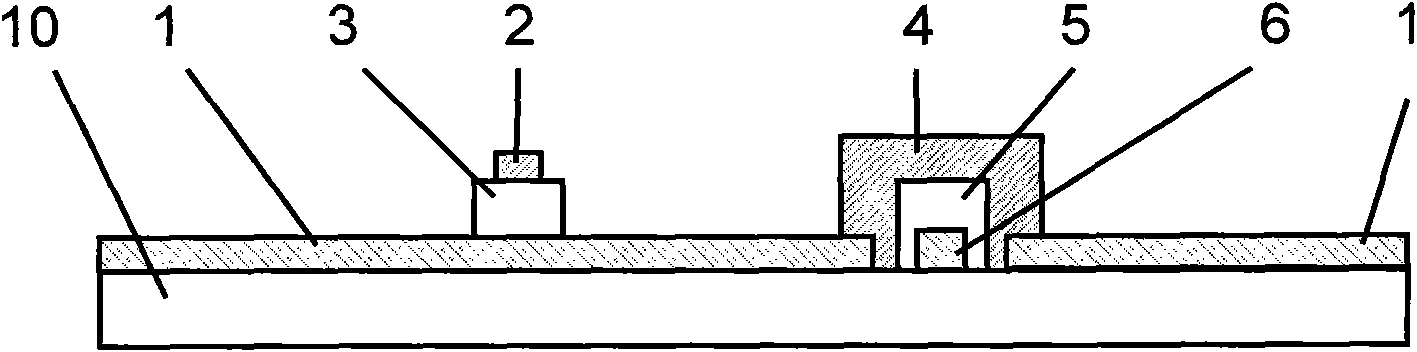

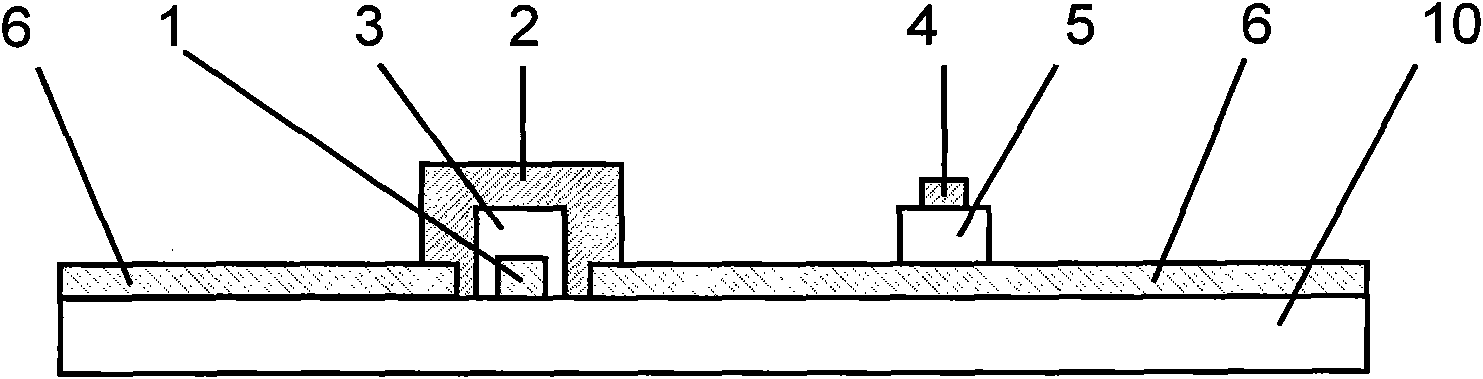

[0035] Such as figure 1 , figure 2 , image 3 As shown, the wiring of the capacitive touch screen of the present invention includes transparent conductive films 1,6, insulating films 3,5 and surface resistance lower than transparent conductive films 1,6 of two groups of wires arranged on the substrate 10 along the X and Y directions. Bridging membranes2,4.

[0036] The structure of the transparent conductive film 1 in the X direction at the intersection with the transparent conductive film 6 in the Y direction includes continuous connections and bridge connections. connection, continuous connection, bridging connection, continuous connection, continuous connection, bridging connection" or "continuous connection, bridging connection, bridging connection, continuous connection, bridging connection, bridging connection", etc.), or irregular arrangement, all The object of the present invention can be realized.

[0037] The structure of the transparent conductive film 6 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com