Capacitance type touch screen and manufacturing method thereof

A technology of a capacitive touch screen and a manufacturing method, which is applied to the input/output process of electrical digital data processing, instruments, and data processing, etc. The effect of electrical interference, improving product quality, reducing line resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

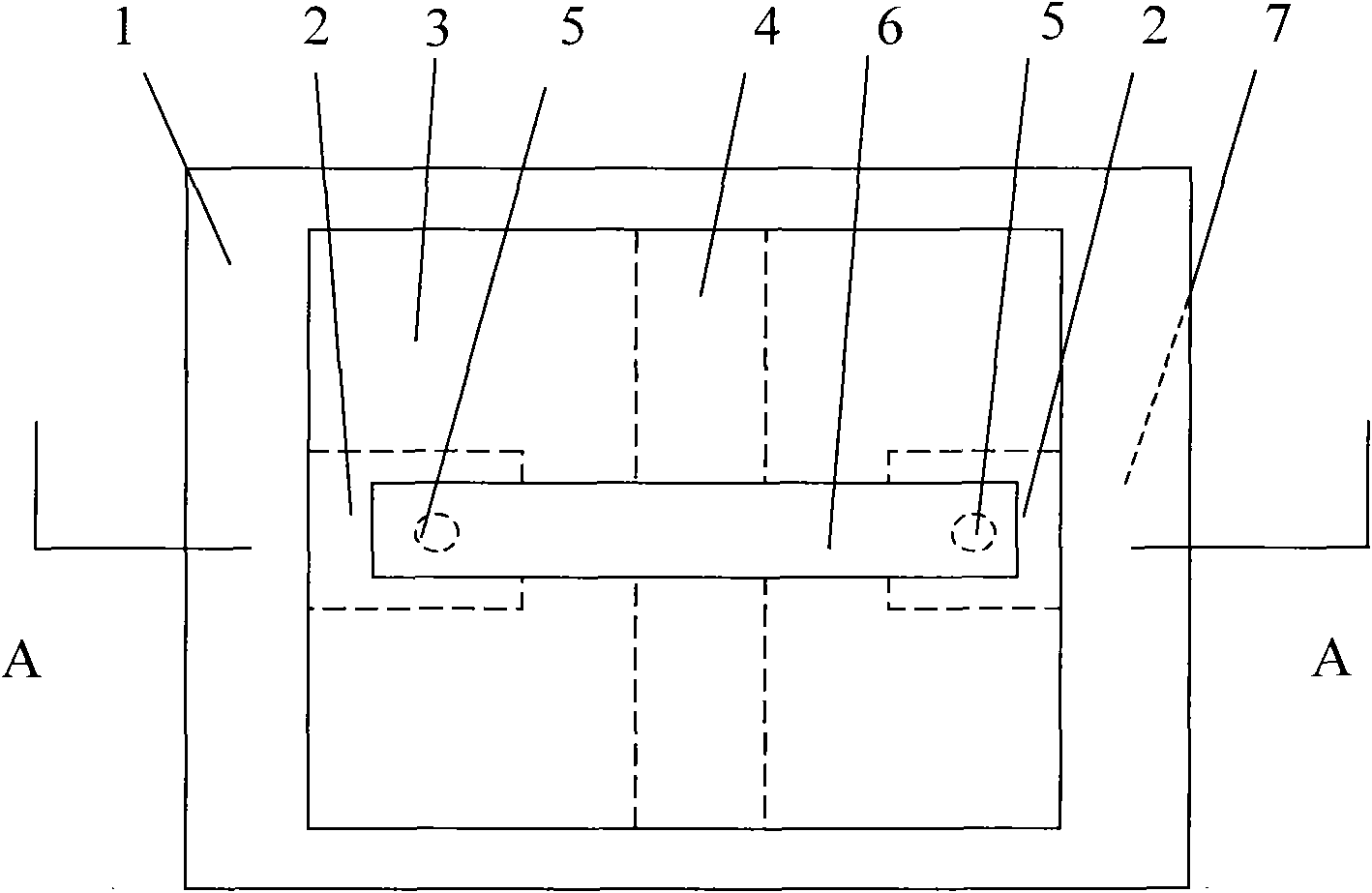

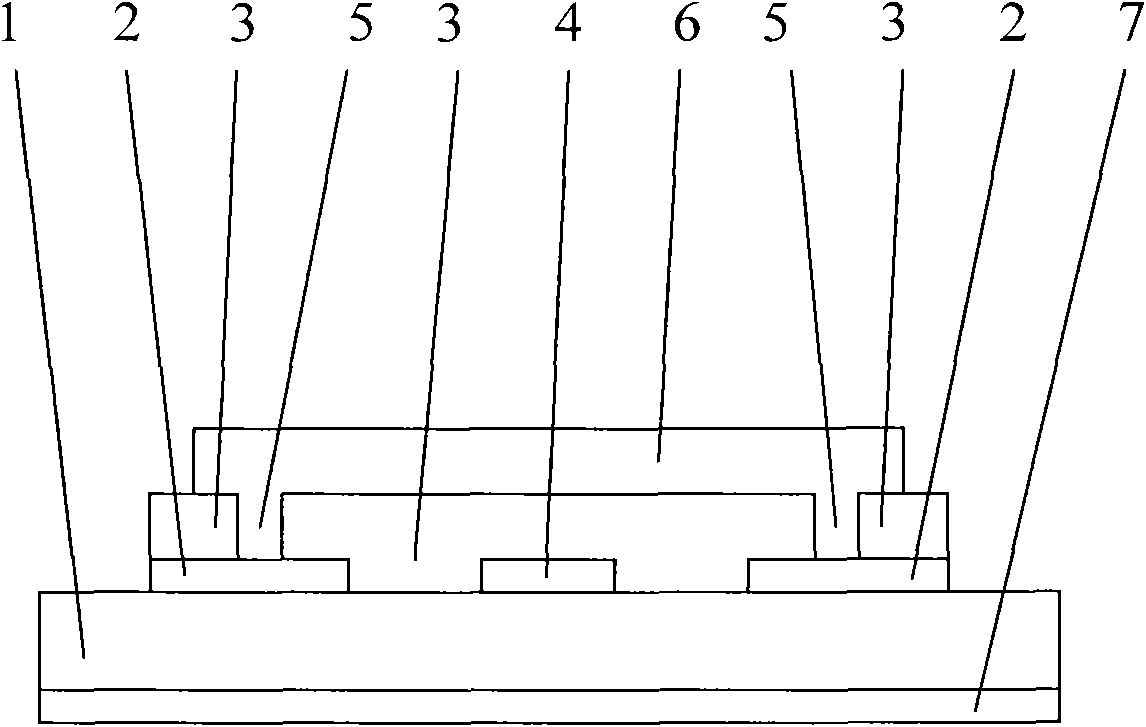

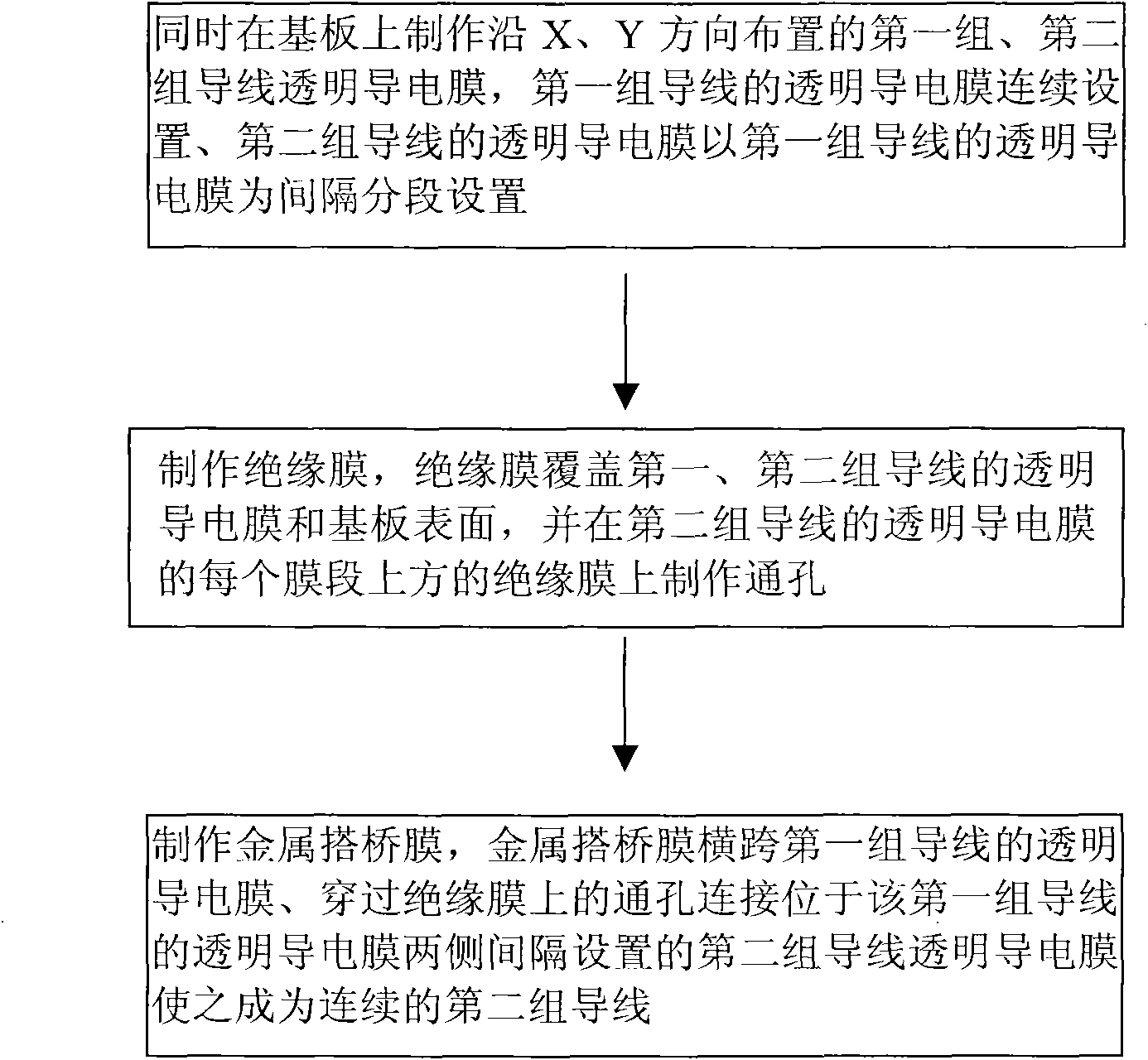

[0032] like figure 1 , figure 2 As shown, the capacitive touch screen of the present invention includes a substrate 1 , transparent conductive films 2 , 4 and an insulating film 3 of two sets of wires arranged on the substrate 1 along X and Y directions.

[0033] The transparent conductive films 4 of the first group of wires in the two groups of wires are arranged continuously, and the transparent conductive films 2 of the second group of wires are arranged in sections at intervals of the transparent conductive films 4 of the first group of wires.

[0034] The insulating film 3 is covered on the surface of the two groups of wire transparent conductive films 2 and 4 and the substrate 1 .

[0035] On the insulating film above each film section of the transparent conductive film 2 of the second group of wires, a through hole 5 is set, and a metal bridging film 6 corresponding to the second group of wires (that is, the metal bridging film 6 corresponding to the second group of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com