Stacked coil device and manufacturing method thereof

A technology of laminated coils and manufacturing methods, applied in coil manufacturing, transformer/inductor coils/windings/connections, inductors with magnetic cores, etc., which can solve the problem of magnetic property degradation of magnetic ceramics, internal conductor disconnection, internal conductors Thickness and other problems, to achieve the effect of relieving internal stress, sufficient stress, and good characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

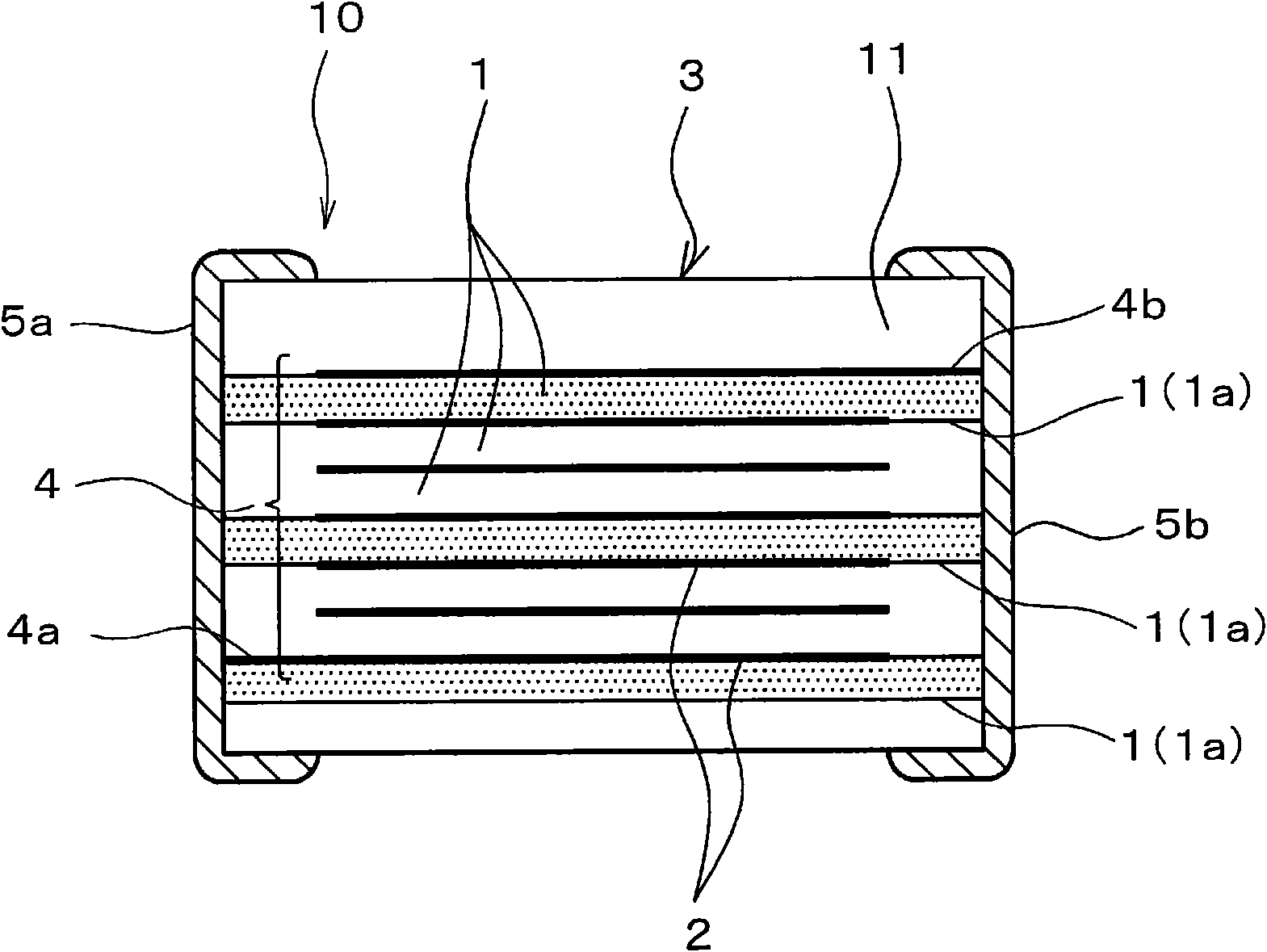

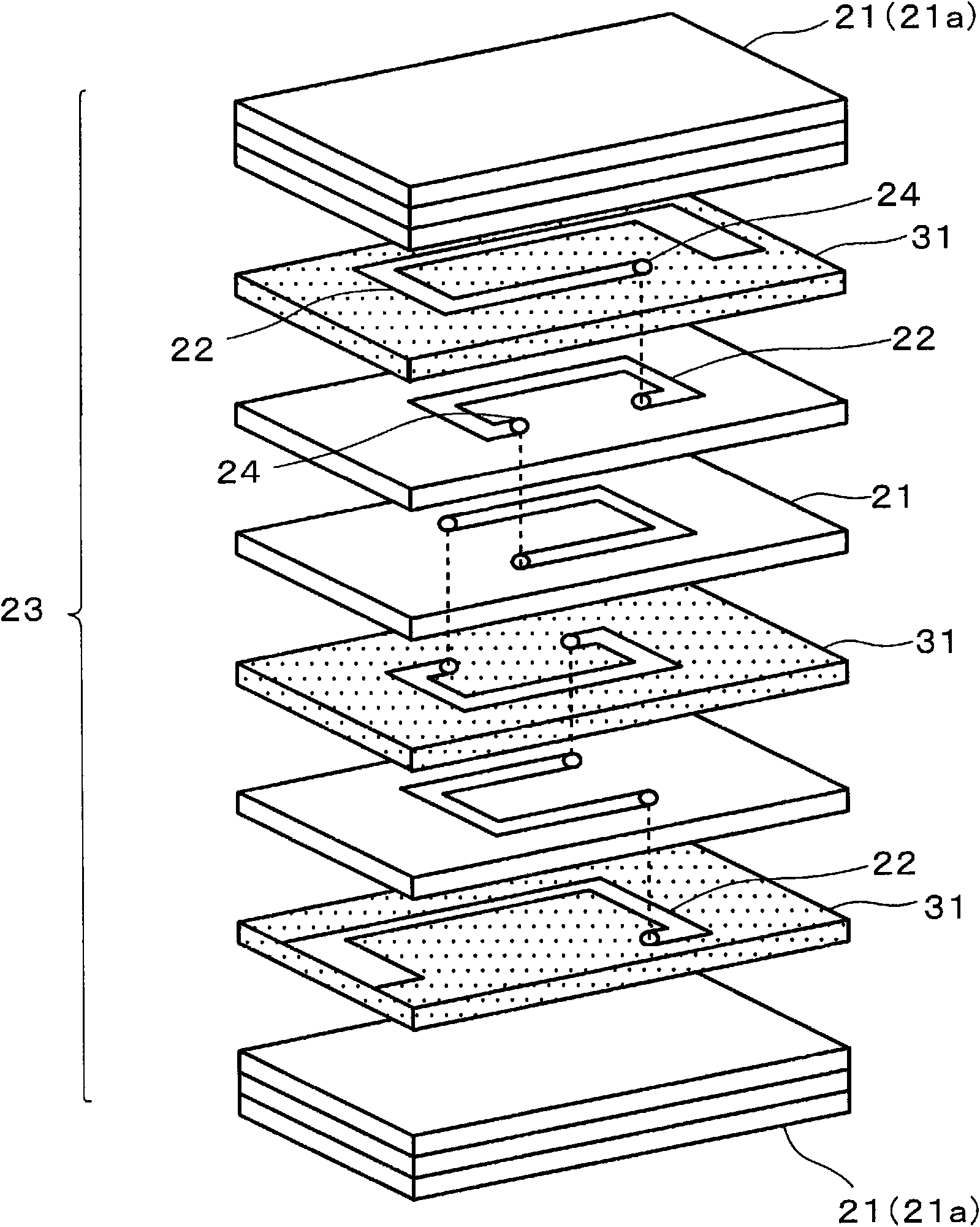

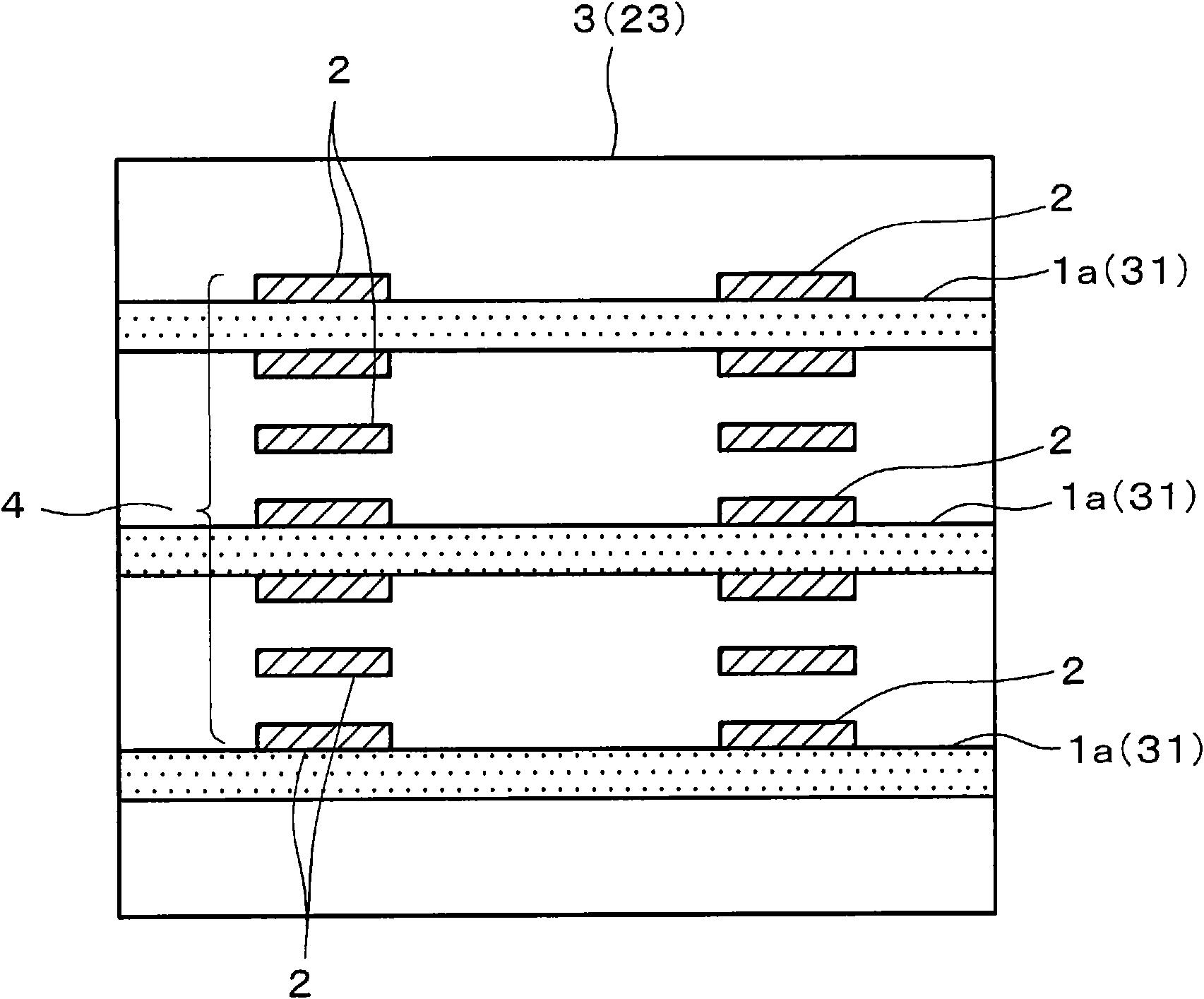

[0061] figure 1 is a schematic front sectional view showing the structure of a laminated coil device (a laminated impedance element in the first embodiment) according to an embodiment of the present invention, figure 2 yes means figure 1 An exploded perspective view of the fabrication method of the laminated coil device, image 3 yes figure 1 Side cross-sectional view of a laminated coil device.

[0062] This laminated coil device 10 includes a magnetic ceramic element 3, and the magnetic ceramic element 3 includes a laminated magnetic ceramic layer 1 and a spiral formed by connecting internal conductors 2 mainly composed of Ag laminated through the magnetic ceramic layer 1. shaped coil 4. Furthermore, a pair of external electrodes 5 a and 5 b are arranged at both ends of the magnetic ceramic element 3 so as to conduct conduction with both ends 4 a and 4 b of the helical coil 4 .

[0063] In addition, among the magnetic ceramic layers 1 constituting the magnetic ceramic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com