Laser LED electrode connection device

A technology of laser diodes and connecting devices, which is applied in the direction of conductive connection, electrical component connection, connection, etc., can solve the problems of complex laser structure, unsafe, short circuit or short circuit, etc. The effect of structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

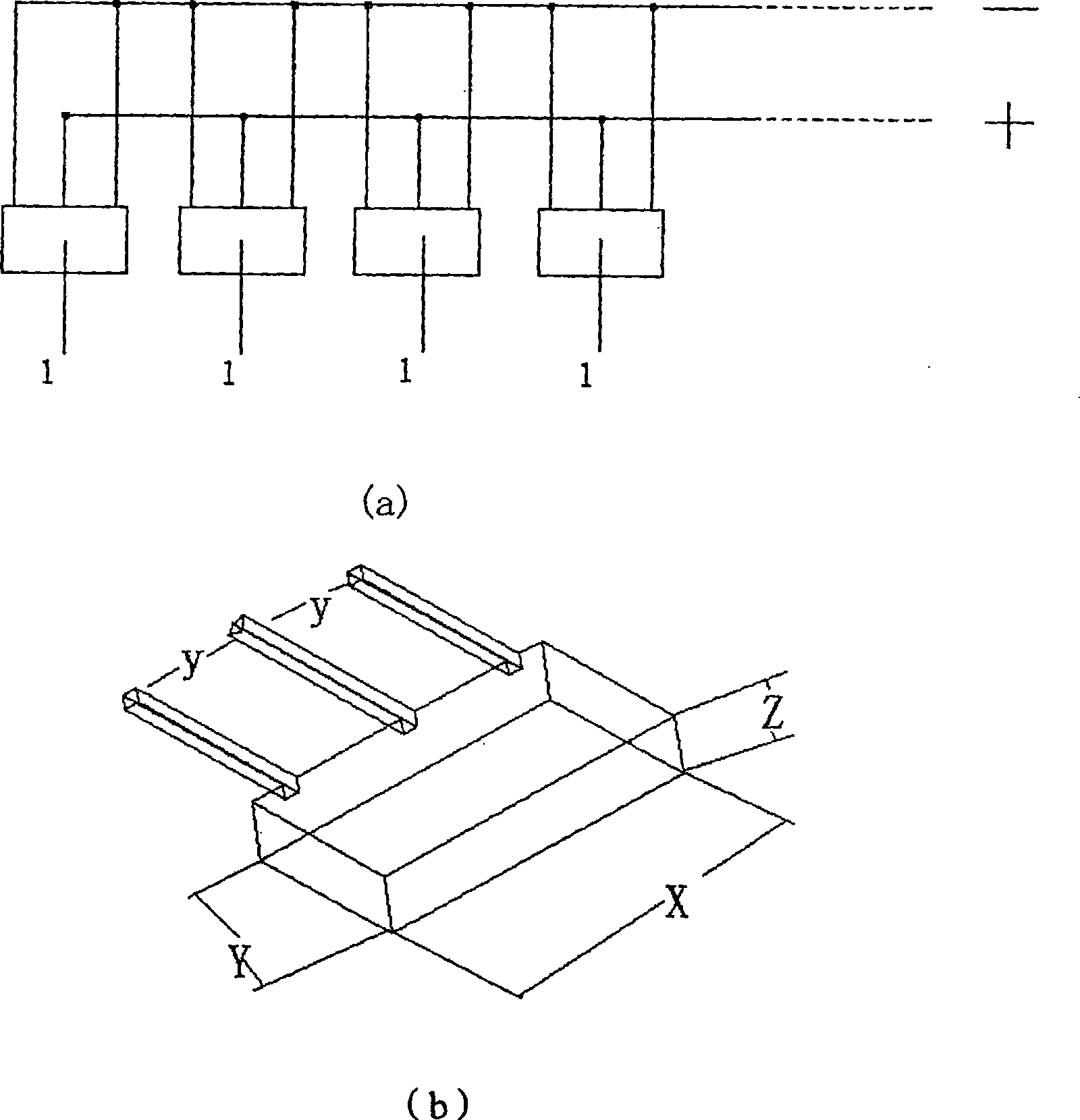

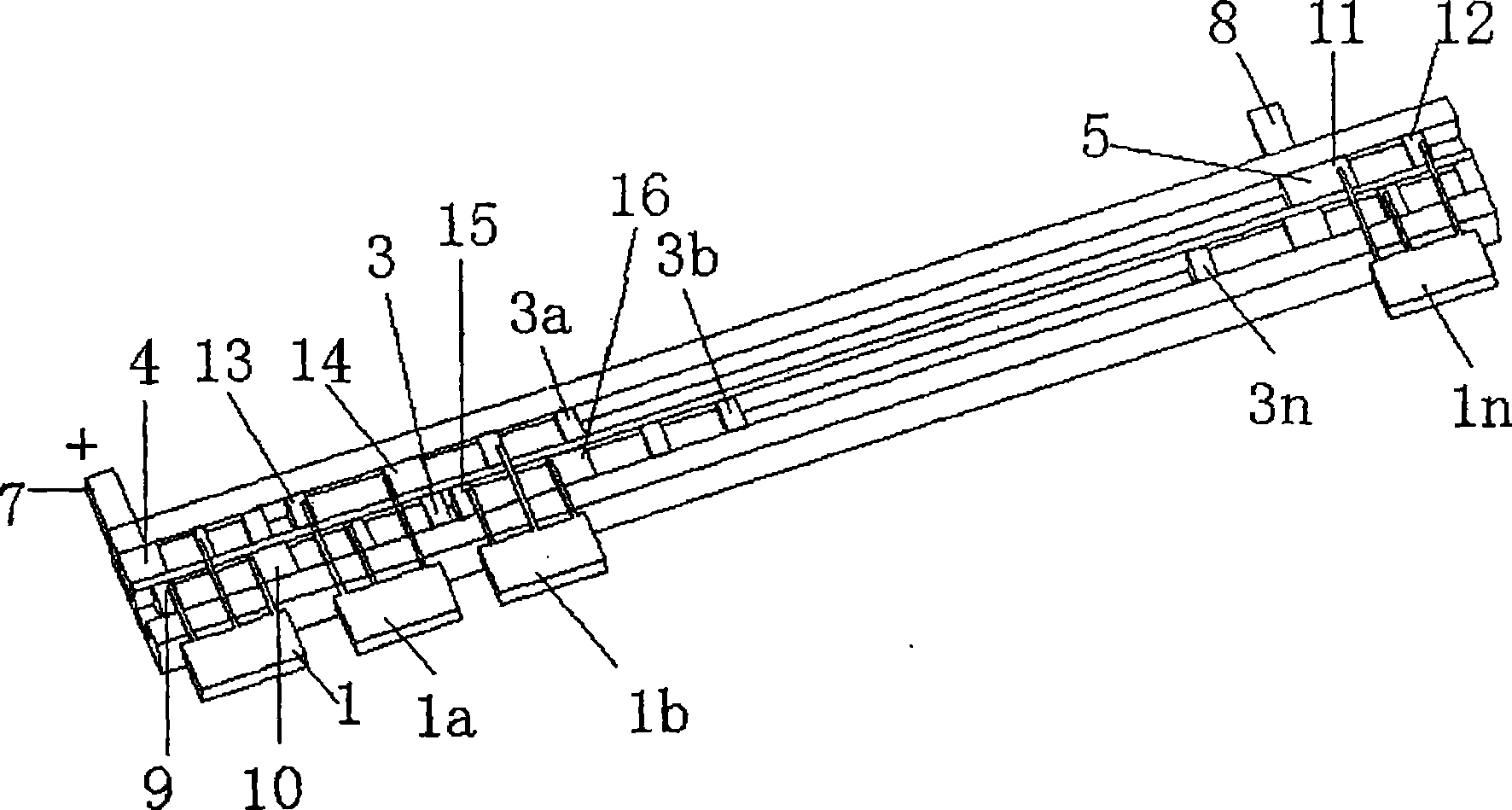

[0047] Combine below Figure 1 to Figure 8 Specific embodiments of the present invention are illustrated:

[0048]The structure of the laser diode used in this embodiment is as figure 1 As shown in (b), the width X is 8mm, the length Y is 10mm, the thickness Z is 3mm, and the distance y between the positive and negative electrodes is 3mm.

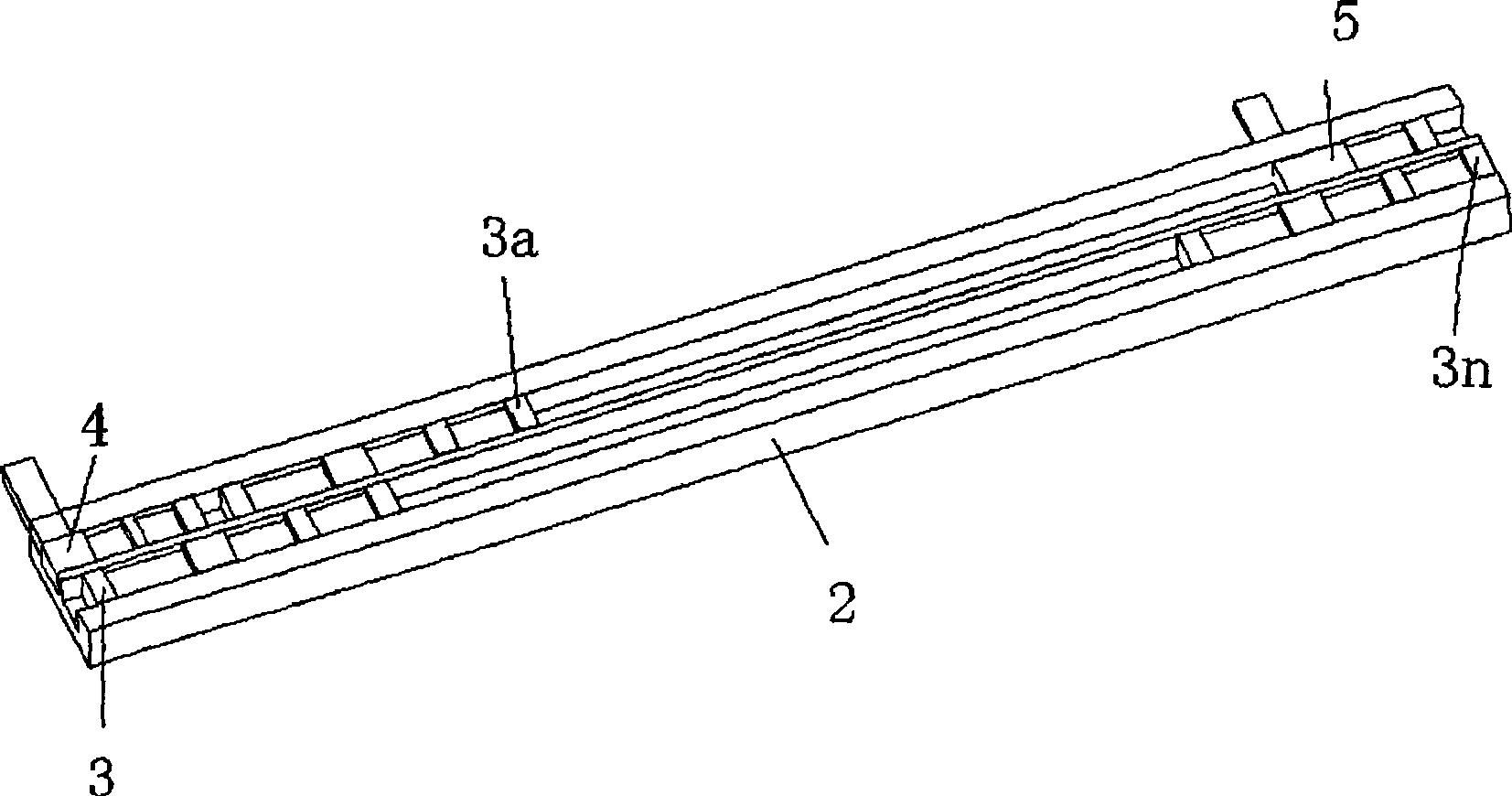

[0049] This embodiment mainly includes a bottom plate 2 made of plastic, a metal strip 3 made of metal, a positive plate 4 of a power supply, a negative plate 5 of a power supply and a plastic cover plate 6. The specific structure is:

[0050] On the plastic bottom plate 2 with a width of 15mm and a thickness of 5mm and a length of 150mm, two rows of the first groove a and the second groove b are engraved. The depth H of the two grooves is 2mm, and the width D is 3mm. The distance between the grooves is 1mm, such as Figure 2~4 shown.

[0051] Carve out two lengths at one end (at 2 mm from the end face) of a metal strip 3 with a width ...

Embodiment 2

[0070] Such as Figure 9 As shown, the structure of this embodiment is the same as that of Embodiment 1, the only difference is that the shape of the bottom plate 2 used is circular, the shape of the corresponding cover plate 6 is also circular, and the metal strips, the positive plate 4 of the power supply , The shape of the negative plate 5 of the power supply is arc-shaped.

[0071] When placed, the distance between the positive plate 4 of the power supply and the negative plate 5 of the power supply is 8mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com