LED lamp

A technology for LED lamps and lamp caps, which is applied to lighting devices, light sources, light source fixing and other directions, can solve the problems of disconnection between lamp caps and lamp housing wires and conductive joints, LED lamps cannot be used, and the fixing effect is not stable enough, so as to improve the fixing effect. Effects that are not easily disjointed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

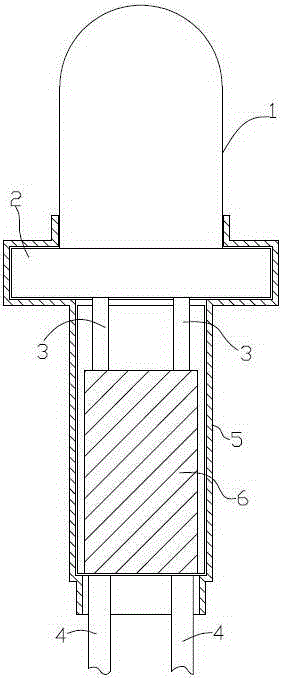

[0011] Such as figure 1 As shown, an LED lamp provided by the present invention includes a lamp base 1, a lamp base 2 is provided at the lower end of the lamp base 1, the radius of the lamp base 2 is larger than that of the lower end of the lamp base 1, two conductive joints 3 are provided at the lower end of the lamp base 1, and the conductive joints 3 passes through the lamp holder and is exposed outside the lamp holder, the conductive joint 3 is welded to the wire 4, and the lower end of the lamp holder, the lamp holder and the wire are evenly positioned in the lamp housing 5. Through the lamp holder, the fixing effect of the lamp holder and the lamp housing is greatly improved.

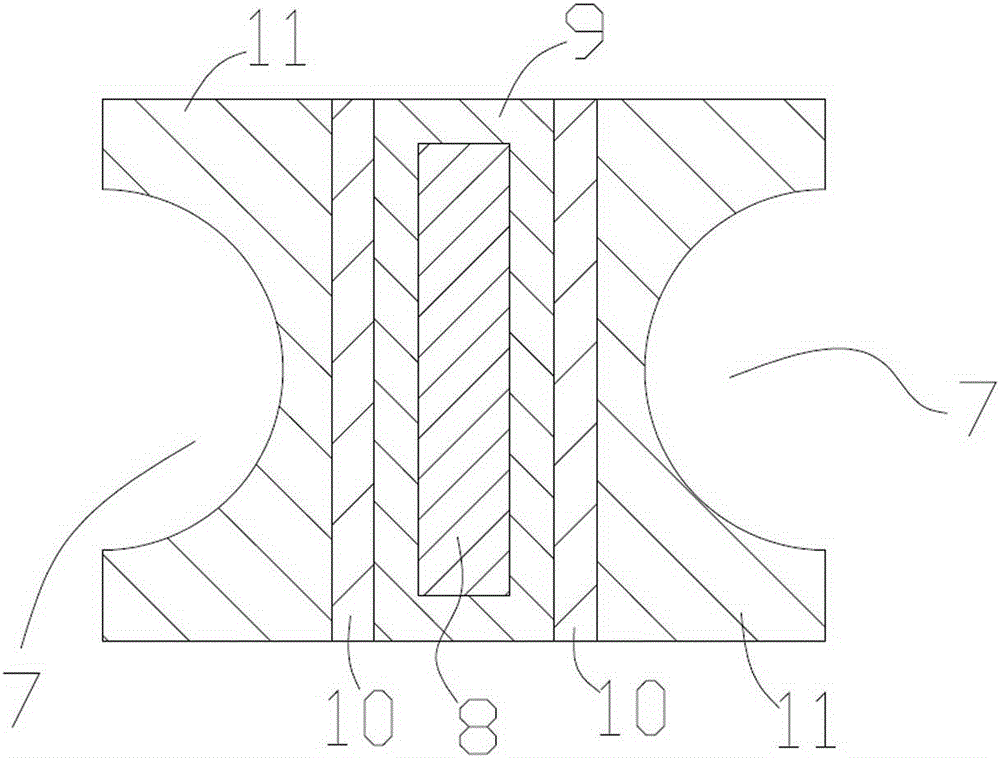

[0012] The lamp housing is also provided with a fixed sleeve 6, such as figure 2 As shown, there are semicircular grooves 7 on both sides of the fixing sleeve 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com