Electronic device and method for manufacturing the electronic device

A manufacturing method and technology of electronic devices, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor/solid-state device components, etc., can solve the problem of weak adhesion of the substrate surface layer, insufficient adhesion strength of the substrate surface layer, and peeling of bonding pads, etc. problems, achieve the effect of reducing process burden, improving peel resistance, and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0021] (Structure of Electronic Devices)

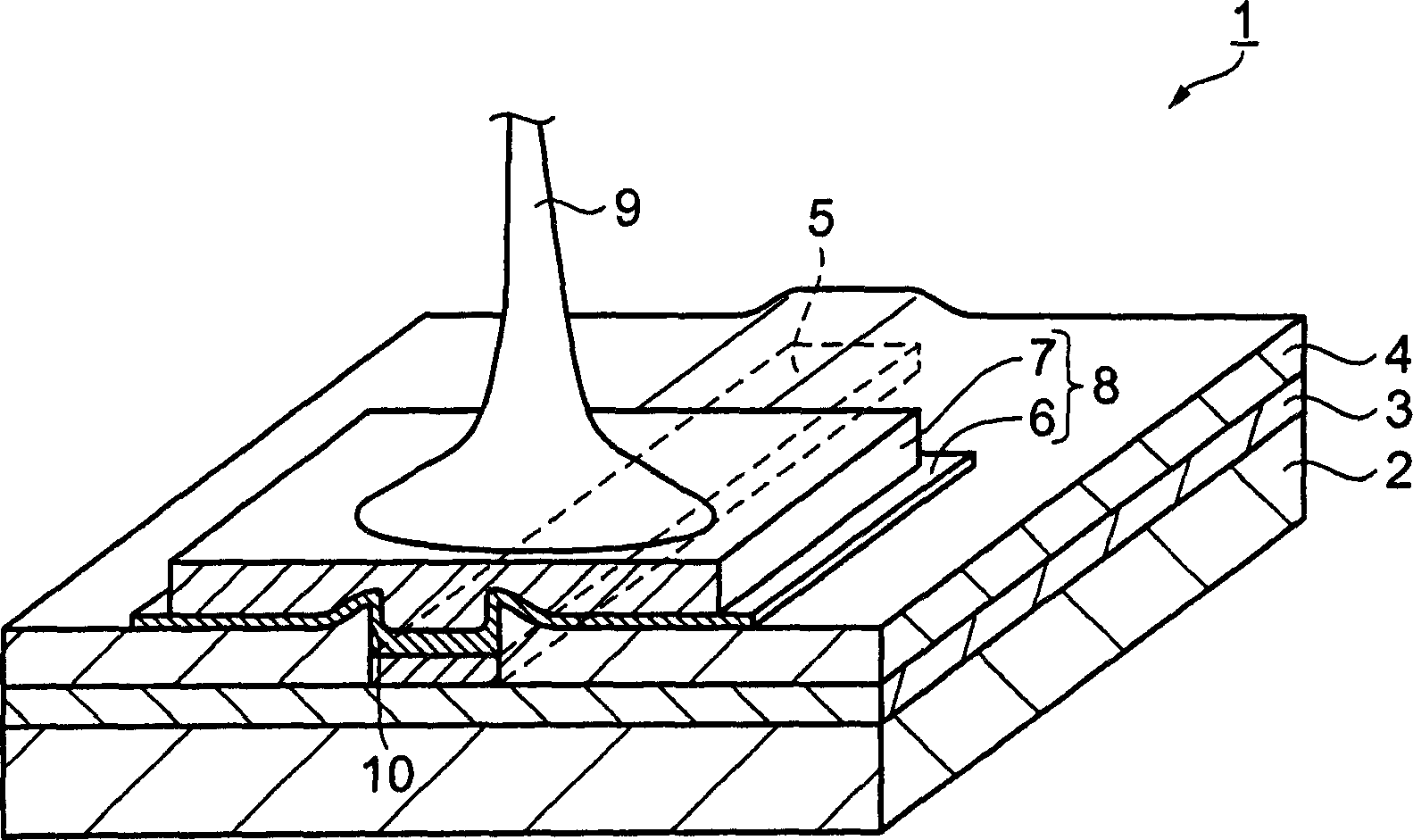

[0022] First, refer to figure 1 The electronic device according to the first embodiment will be described. figure 1 It is a partially broken perspective view showing the main part structure of the electronic device according to the first embodiment.

[0023] figure 1 Among them, an integrated circuit 1 as an electronic device includes: a silicon substrate 2 formed with semiconductor elements (not shown); an insulating layer 3 formed of BPSG (Boron-doped Phospho Silicate Glass) or the like formed on the silicon substrate 2; Conductive wiring 5 composed of Al or the like for semiconductor element connection; and SiO as the conductive wiring 5 covered 2 or the covering layer 4 of a Si-based insulating layer made of SiN or the like. Bonding pads 8 connected to conductive wiring 5 through contact holes 10 are formed on covering layer 4 , and bonding pads 8 are connected to a lead frame (not shown) via bonding wires 9 .

[0024] Bondin...

no. 2 Embodiment approach

[0050] Below, refer to Figure 5 , the second embodiment of the present invention will be described focusing on the differences from the first embodiment. Figure 5 It is a partially broken perspective view showing the main part structure of the electronic device according to the second embodiment.

[0051] exist Figure 5 Among them, the integrated circuit 20 as an electronic device includes: a silicon substrate 21 formed with a semiconductor element (not shown); an insulating layer 22 as a Si-based insulating layer formed on the silicon substrate 21; a bank layer 23; The conductive wiring 25 and the bonding pad 26 are integrally formed by the droplet discharge method. The bank layer 23 is formed of a photosensitive resin or the like, and is patterned using a photolithography technique so as to divide the formation regions of the conductive wiring 25 and the bonding pad 26 .

[0052] The conductive wiring 25 and the bonding pad 26 are formed to have a laminated structure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com