Liquid crystal lens element and optical head device

A liquid crystal lens and component technology, which is applied to optical recording heads, beam guiding devices, optics, etc., can solve the problems of complicated mechanism design, easy short circuit, and easy disconnection of the transparent electrode 320.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0310] Below, refer to Image 6 The details of the liquid crystal lens element 20 of the present invention shown in the second embodiment will be described.

[0311] Example.

[0312] First, a method of manufacturing the liquid crystal lens element 20 will be described.

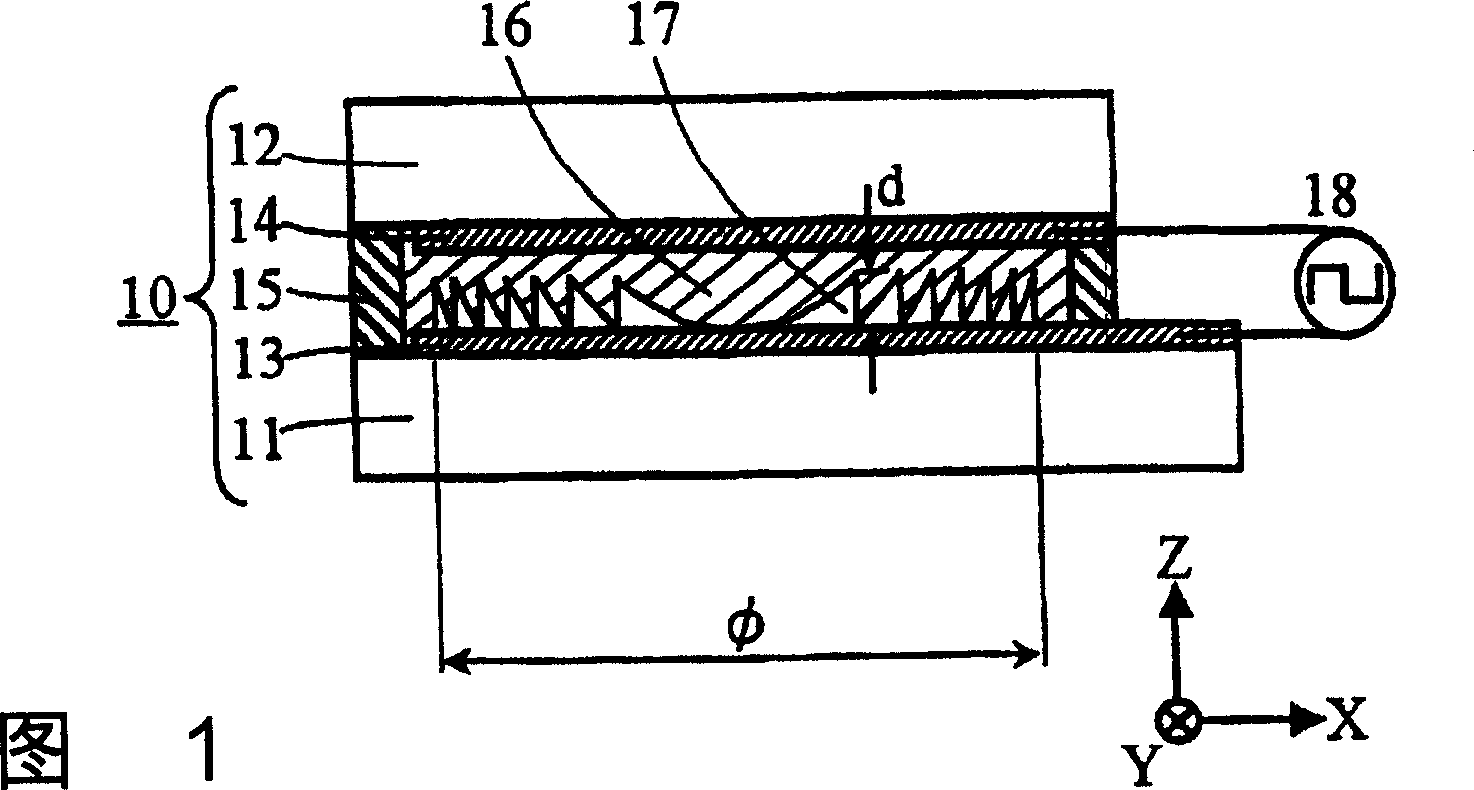

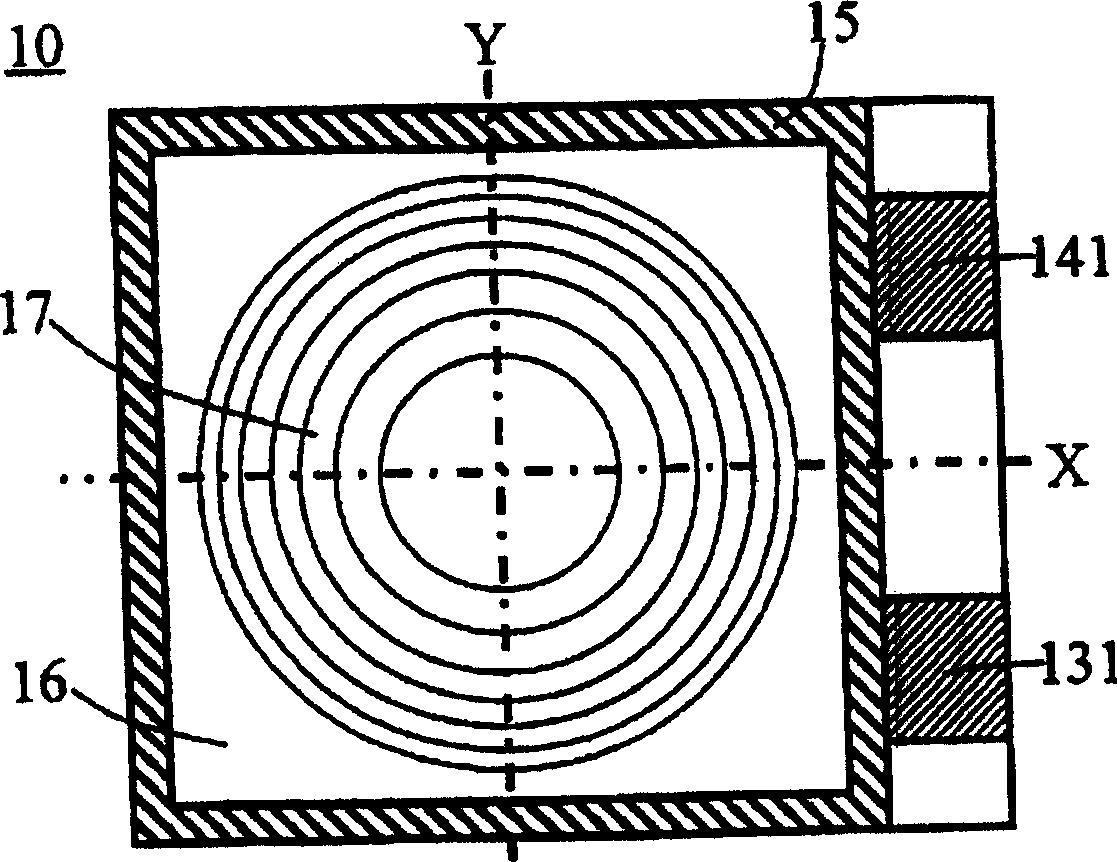

[0313] A transparent conductive film (ITO film) is formed on a glass substrate of the transparent substrate 11 as the transparent electrode 13 . Then coat the transparent electrode 13 with a refractive index n s (=1.66) uniform refractive index material, that is, photosensitive polyimide, was formed into a film thickness d (=5.5 μmm).

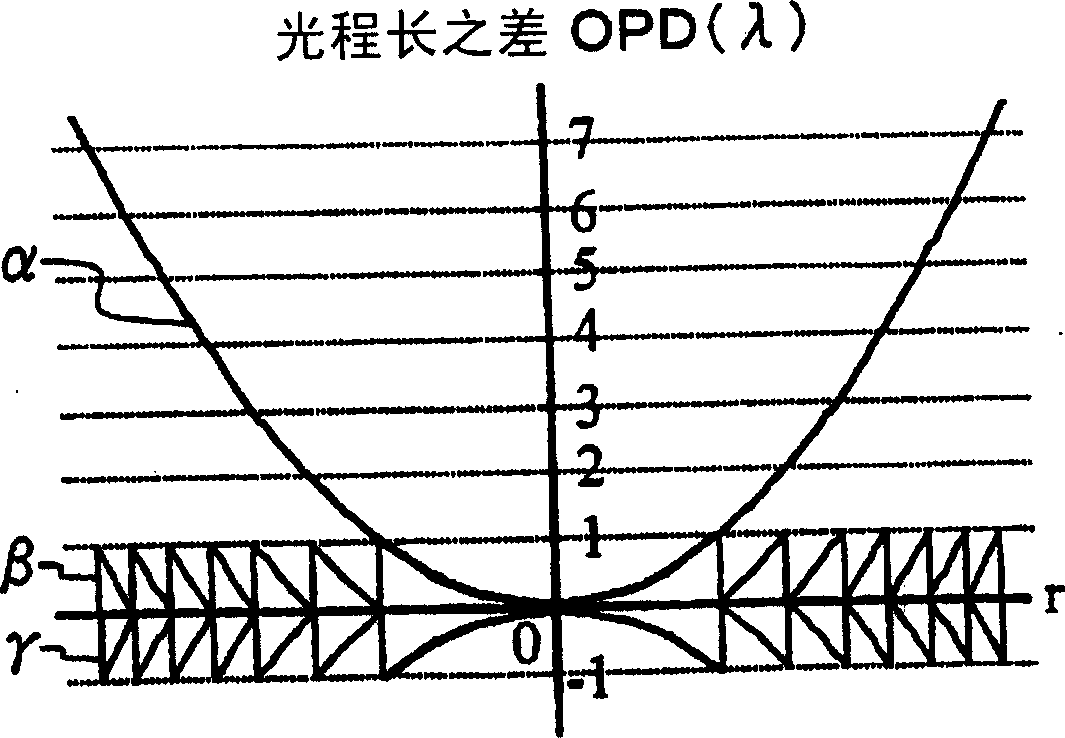

[0314] Then, using the equivalent of image 3 A step mask whose ultraviolet transmittance is distributed in the radial direction as in the shape of the curve β, irradiates the photosensitive polyimide with ultraviolet rays, sinters the step mask pattern, and then develops it. As a result, in the region of the effective diameter φ (= 4.9 mm), the cross-sectional shape is s...

example 2

[0344] Next, it will be described that the liquid crystal lens element 20 of the aforementioned [Example 1] is housed in the Figure 11 A specific example of the optical head device 70 according to the sixth embodiment shown. In addition, since the structure of this optical head apparatus 70 was already demonstrated in 6th Embodiment, it is abbreviate|omitted here.

[0345] When recording and reproducing a single-layer disc D for DVD with a cover layer thickness of 0.60mm, if the applied voltage of the liquid crystal lens element 20 is V 0 = about 2.5V, the incident light is focused on the information recording layer by the objective lens 6 .

[0346] For the double-layer disc D used for DVD, if the applied voltage of the liquid crystal lens element 20 is V +1 (=0V), the incident light is focused on the information recording layer with a cover layer thickness of 0.57mm, and if the facility applied voltage is about V-1 (=6V), the incident light is focused on the information r...

example 3

[0351] Next, the volume resistivity p F Greater than or equal to the volume resistivity ρ of the liquid crystal 16 LC For examples of materials, refer to Image 6 Described below.

[0352] First, a method of manufacturing the concave-convex portion 17 in the liquid crystal lens element 20 will be described.

[0353] On the transparent electrode 13 formed into a film on the glass substrate of the transparent substrate 11, the ordinary light refractive index n of the liquid crystal 16 is formed by sputtering. o Substantially equal refractive index n s (=1.507) uniform refractive index material SiOxNy (here, x and y represent the element ratio of O and N) thin film. Here, a Si sputtering target and a discharge gas in which oxygen and nitrogen are mixed in Ar gas are used, and the refractive index n is formed in this way. s A transparent SiOxNy film with a uniform refractive index and a film thickness d (= 2.94 μm). Relative permittivity ε of SiOxNy F is 4.0, volume resisti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com