Photovoltaic anti-glare panel

An anti-glare panel and photovoltaic technology, applied in photovoltaic power generation, protective equipment, electric vehicles, etc., can solve problems affecting the power generation efficiency of anti-glare panels, and achieve the effect of improving power generation efficiency and reducing shading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

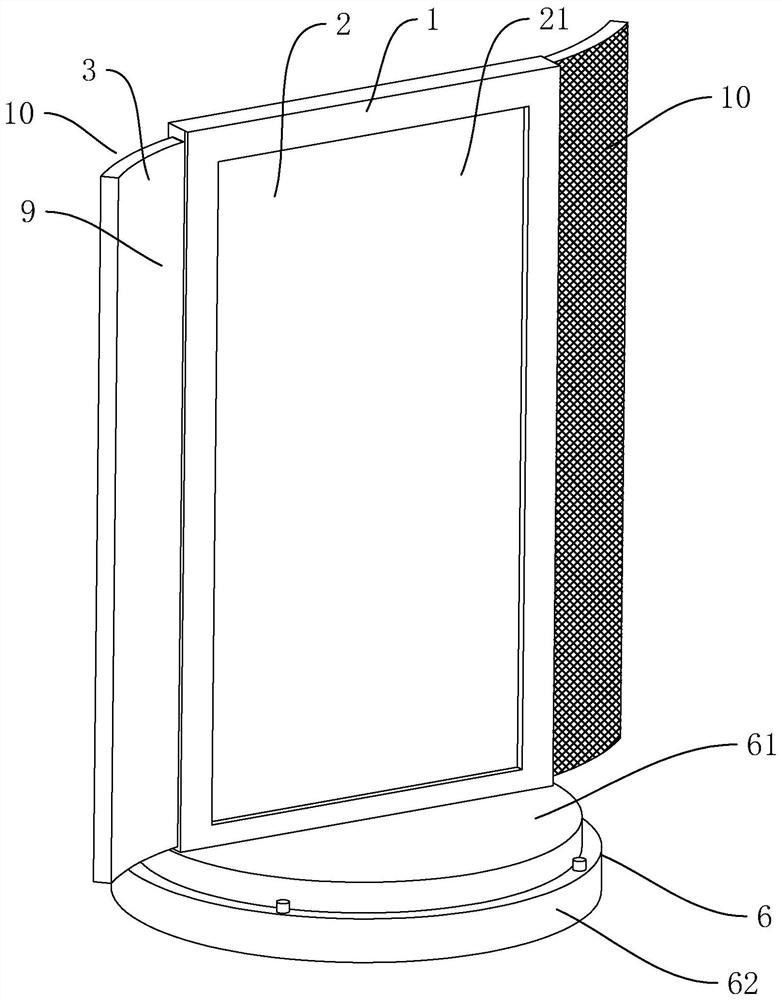

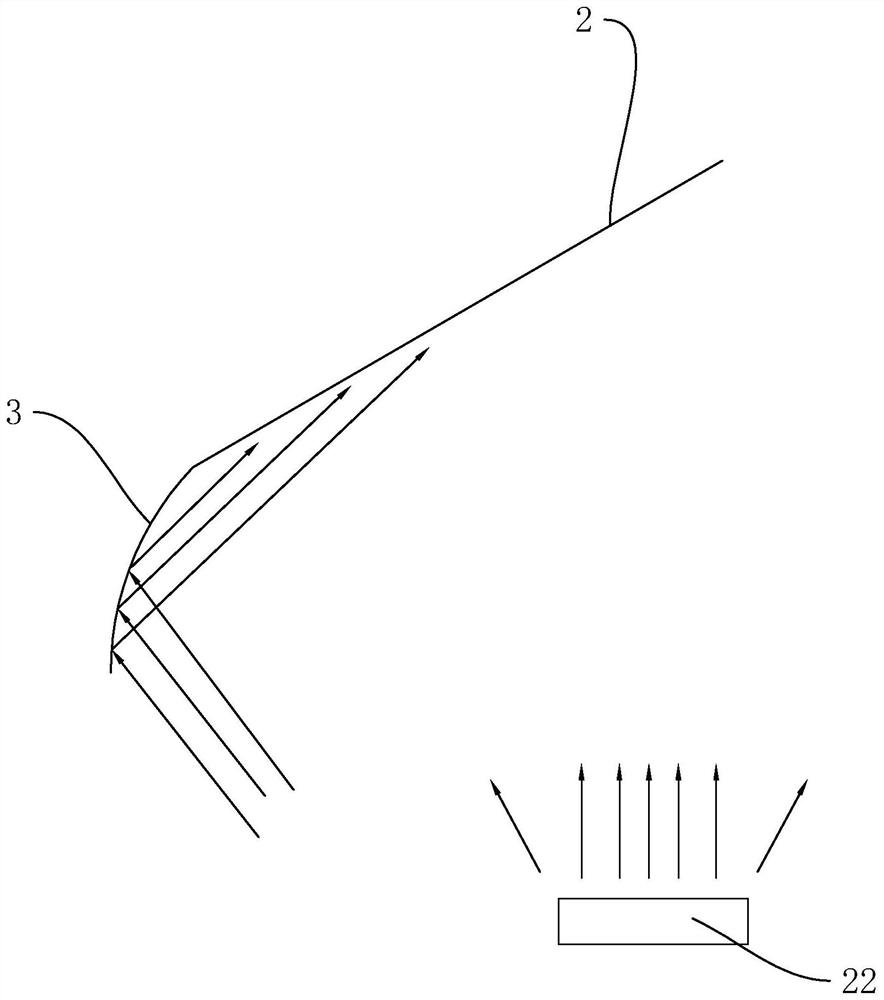

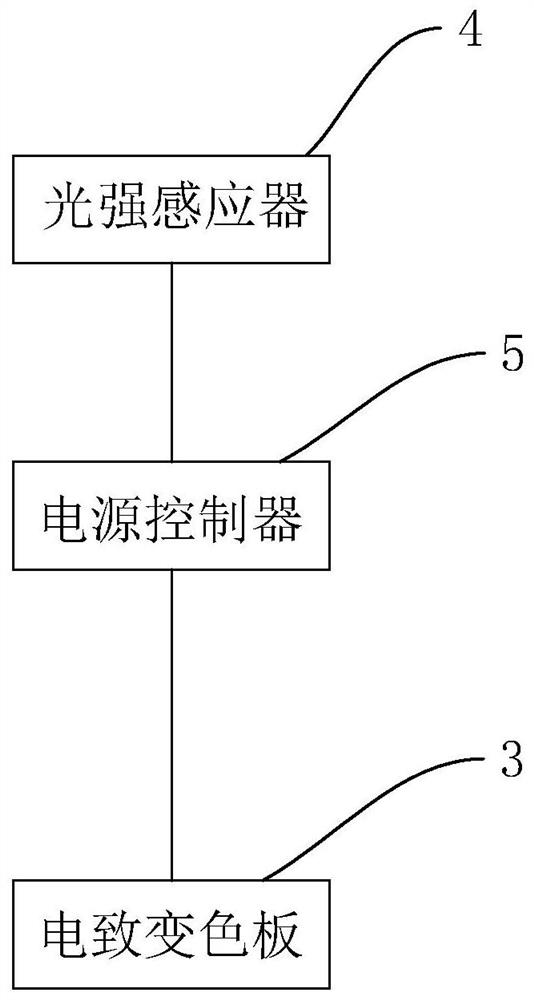

[0037]EXAMPLE 1, the present application discloses a photovoltaic anti-glare plate. Referfigure 1 withfigure 2 The photovoltaic glare plate includes a base 6, a frame 1 fixed to the base 6 and a photovoltaic assembly 2 provided in the frame 1, the photovoltaic assembly 2 is a double-sided photovoltaic assembly 2, so that the light-free glare plate can be collected on both sides. The light source is powered, and the electrochromic plate 3 is also attached to the left and right of the frame 1, the electrochromic plate 3 is electrochromic glass, and is curved, and the bending direction of the two electrochromic plates 3 is exactly the opposite. The electrochromic plate 3 is a smooth surface 9 in the inner recess, at night, the light of the car is directly illuminated on the photovoltaic assembly 2, and the car lamp 22 light in the smooth surface 9 can be used. Reflected onto the photovoltaic assembly 2 for power generation, so that the anti-glare plate can collect more weak light at ni...

Embodiment 2

[0042]Example 2, seeFigure 7 withFigure 8 The present embodiment differs from the first embodiment in that the automatic reset mechanism 7 includes a cylindrical body 77, a sealing plate one 78, and a sealing plate 2 79, and the upper end of the cylinder 77 is fixedly sealed with the turntable 61, and the lower end and fixation of the cylinder 77 The disk 62 rotates the sealing connection, the sealing plate one 78 and the seal two are provided in the cylinder 77, the sealing plate one 78 is fixed to the turntable 61, the sealing plate 2 79 is fixedly connected to the fixed disk 62, the sealing plate one 78 and the sealing plate 2 79 is connected to the rubber strip 14, the sealing plate one 78, the sealing plate 2 79, the cylinder 77, the turntable 61, and the fixing disk 62 constitute two constant closed air pressure chambers 80, and the two air pressure chamber 80 is filled. There is a gas, the air pressure in the two air pressure chambers 80 is the same, and the atmospheric press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com