Preparation method of electrochemical combined electrode

A combined electrode and electrochemical technology, applied in the direction of material electrochemical variables, can solve the problems of difficult cleaning, high production cost, and poor temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

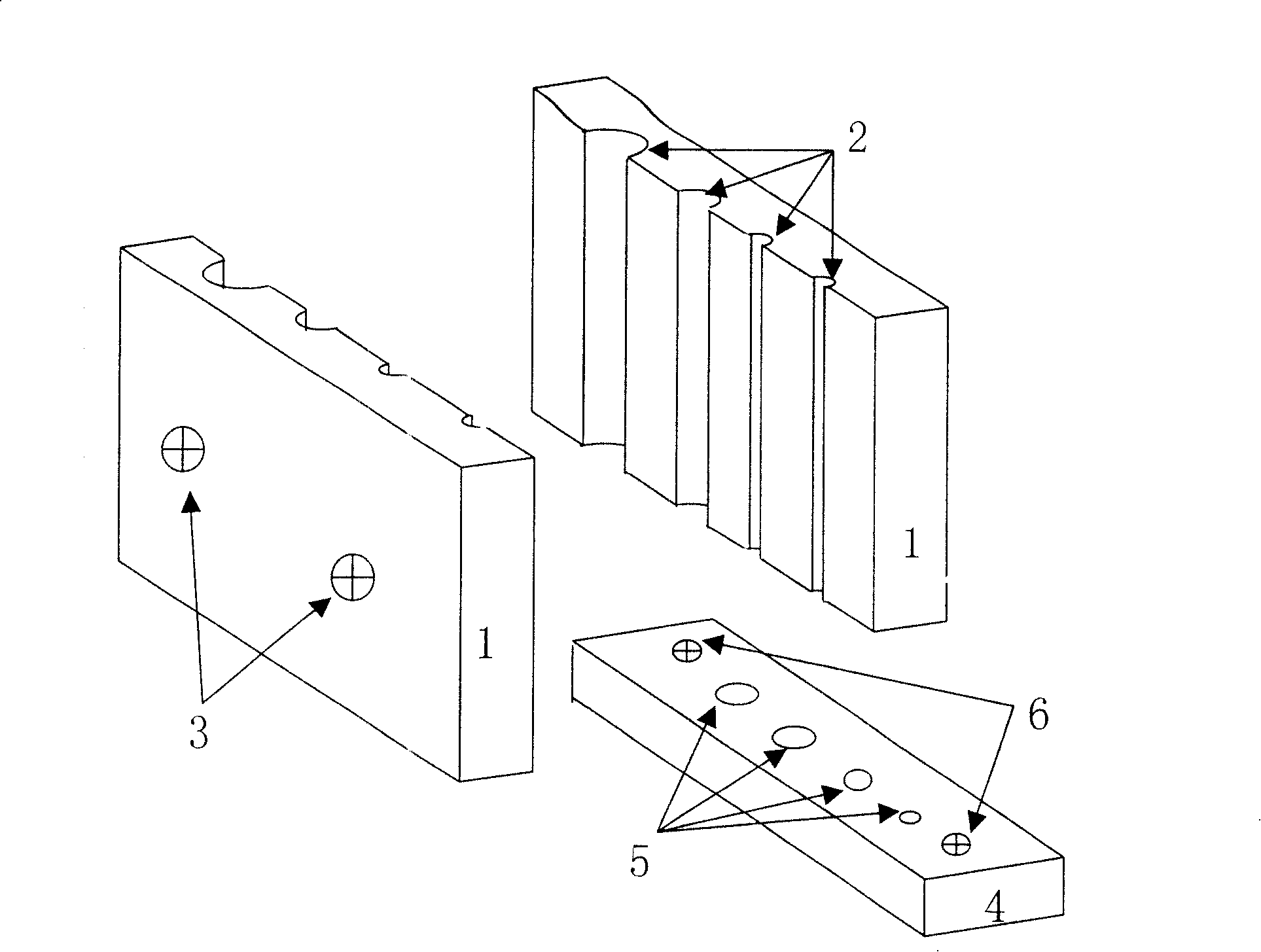

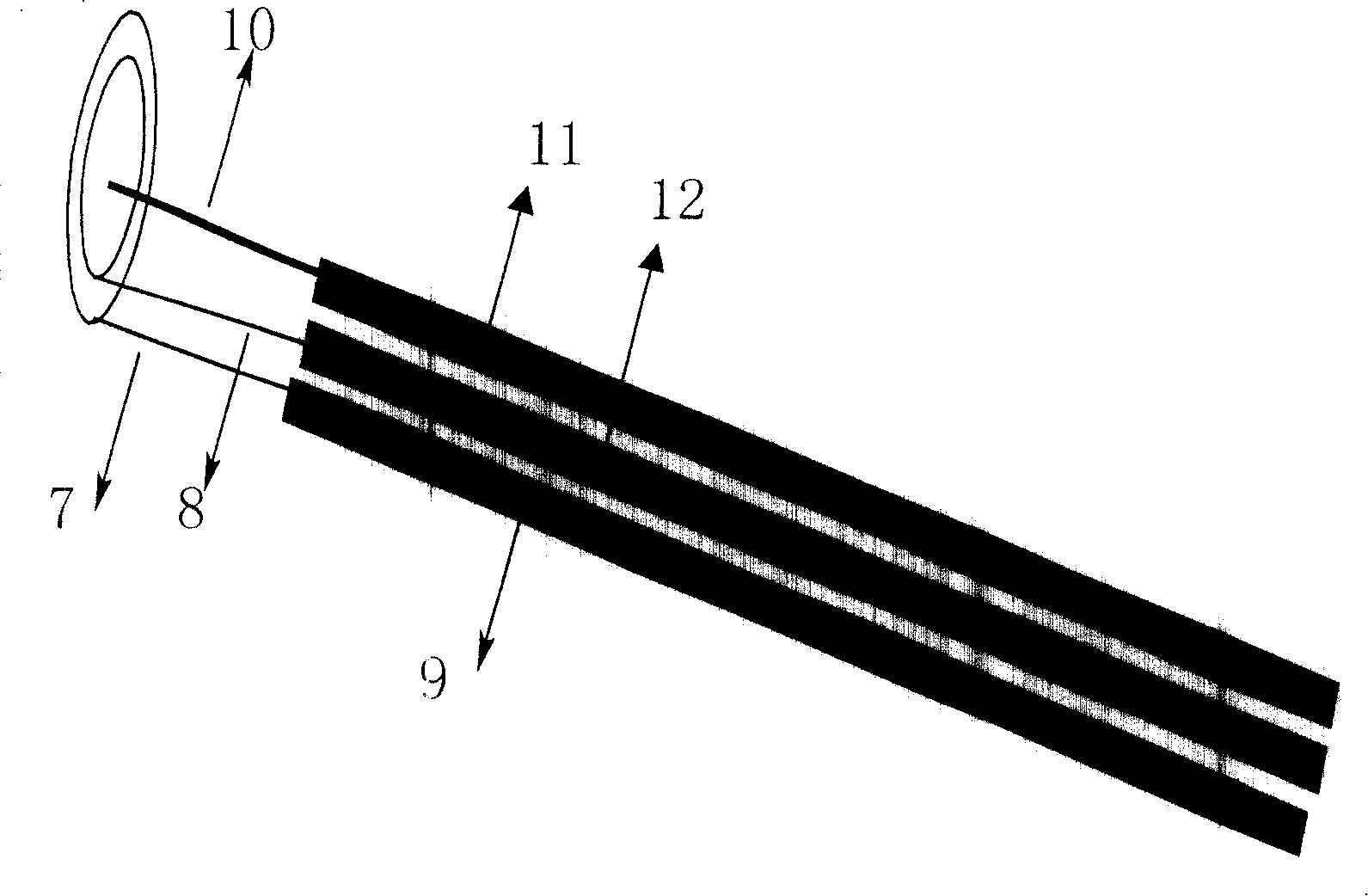

[0016] press figure 1 As shown, first, spray the release agent MR-1 in the electrode hole 2 and the positioning hole 5, and insert the electrode matrix material 10 with a diameter of 0.3cm and a length of 1cm as the working electrode into a conductive working electrode matrix material supporting copper Rod 11, the hole-shaped silver reference electrode 8 has a thickness of 0.5mm, an inner diameter of 0.9cm, and a length of 1cm. The lower end is welded to the reference electrode supporting copper rod 12. The hole-shaped platinum counter electrode 7 has a thickness of 0.1mm, an inner diameter of 1.0cm, and a length of 1cm. , The lower end is welded with the counter electrode supporting copper rod 9, the working electrode base material 10 is in the middle, from the inside to the outside are the ring-shaped reference electrode silver sheet 8, the ring-shaped counter electrode platinum sheet 7, and the top ends of the three are on the same plane. The electrode supporting copper rod is...

Embodiment 2

[0018] The working electrode base material 10 is platinum wire, the working surface diameter is 1 mm, the length is 0.8 cm, the hole-shaped silver reference electrode 8 is 0.3 mm thick, the inner diameter is 0.6 cm, and the length is 0.8 cm. The hole-shaped platinum counter electrode 7 is 0.3 mm thick and the inner The diameter is 0.8cm and the length is 0.8cm. The operation process is the same as in Example 1.

Embodiment 3

[0020] The working electrode base material 10 is gold wire, the working surface diameter is 1mm, the length is 0.5cm, the hole-shaped silver reference electrode 8 is 0.1mm thick, the inner diameter is 0.2cm, the length is 0.5cm, and the hole-shaped platinum counter electrode 7 is 0.1mm thick and the inner diameter 0.3cm, 0.5cm long, the specific operation process is as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com