Laminated conductive rotary slip ring and producing process

A conductive ring and laminated technology, which is applied in the field of rotary slip ring type circuit connection joints, can solve the problems of many processes, high manufacturing cost, and high labor intensity, and achieve the effect of simple process, high manufacturing cost, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

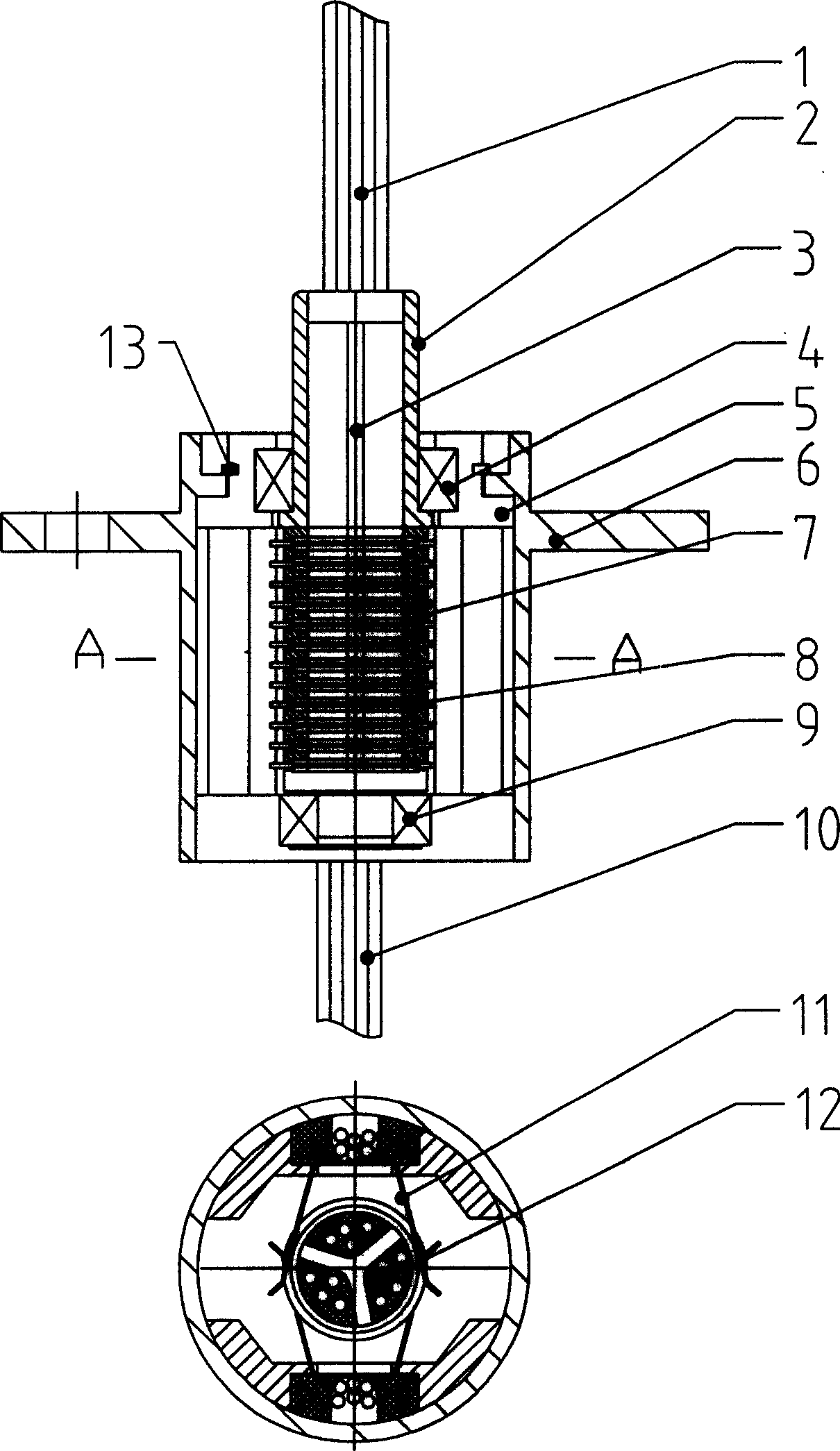

example 1

[0049] Example 1: Now manufacture 1000 pieces of 12-wire new conductive ring rotating shaft:

[0050] It takes 40 man-hours to process 1,000 pieces of 12-wire "Lite" 6023 conductive rotating shafts; but it only takes 6 man-hours to manufacture 1,000 pieces of 12-wire new-type conductive ring rotating shafts, and the production efficiency is increased by 5 times.

[0051] The qualified rate of "Lite" 6023 type conductive rotary shaft dust in production is 50%; while the qualified rate of new conductive ring rotary shaft products is 98%, saving 30,000 yuan per 1,000 products.

[0052] The main part of the newly designed slip ring is the rotating shaft of the conductive ring. It uses a set of molds to produce the mandrel, insulating sheet, and bearing sleeve, and they are used as standard parts for all types of products, so it can save mold costs by 80%, about 80,000 yuan.

[0053] The technical indicators tested by the experiment can reach the level of imported products.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com