High-speed high-precision built-in dynamic and static piezoelectric main shaft

A dynamic and static piezoelectric, high-precision technology, applied in the direction of large fixed members, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems affecting the machining accuracy and efficiency of CNC machine tools, and achieve simple structure, high rotation accuracy, The effect of averaging error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the teachings of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

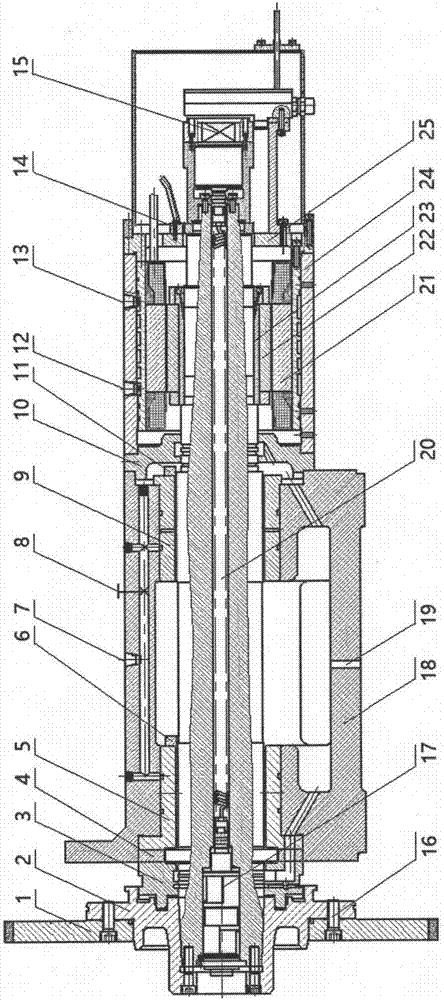

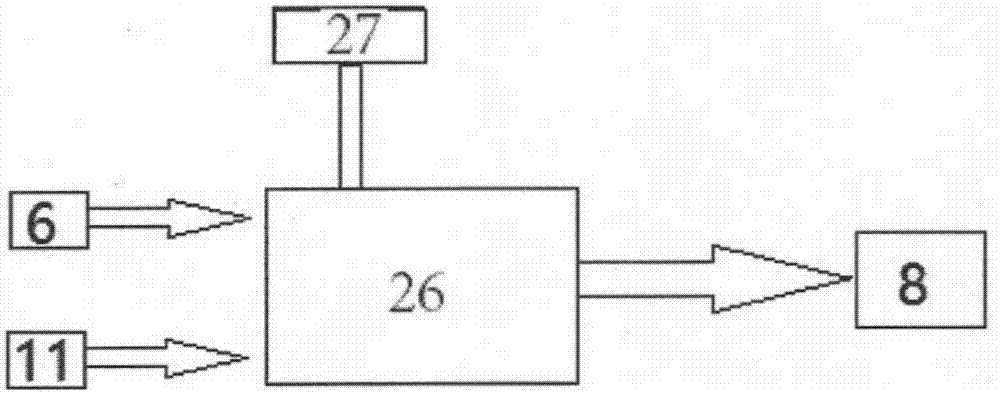

[0022] combine figure 1 and figure 2 , a high-speed and high-precision built-in dynamic and static piezoelectric spindle provided by the present invention is composed of a grinding wheel 1, a flange 2, a front bearing cover 3, an adjusting gasket 4, a front bearing 5, a temperature sensor 6, and an oil inlet 7 , flow regulating valve 8, rear bearing 9, rear bearing end cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com