A fast polishing device

A fast, grinding technology, applied in the field of grinding tools, can solve the problem of oil storage effect not reaching the ideal effect, etc., achieve the effect of great practical and popularization value, improve use performance, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

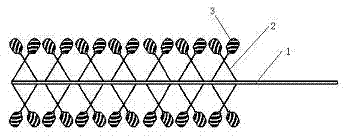

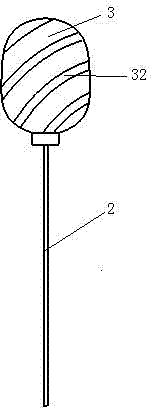

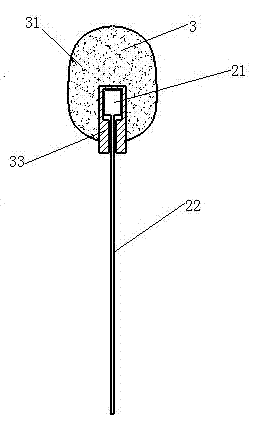

[0015] Refer to attached figure 1 , attached figure 2 , attached image 3 , a kind of fast polishing device of the present invention, is made up of main rod 1, grinding branch 2, grinding head 3, is provided with the grinding branch 2 that forms along the axial staggering inclination on main rod 1, and described grinding branch 2 is An elastic cylinder, the grinding branch 2 is composed of a grinding branch 21 and a branch 22, the branch 22 is fixed on the main rod 1, the grinding branch 21 is a head body larger than the diameter of the branch 22, and the grinding branch 21 is matched with the rotary sleeve 33 in the grinding head 3; the end of each grinding branch 2 is provided with a grinding head 3; the grinding head 3 is a grinding head body that can rotate along the grinding branch 2, and the grinding head 3 consists of 31. The groove 32 and the rotary sleeve 33 are composed of a head body 31 fixed on the periphery of the rotary sleeve 33, and the groove 32 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com