Self-locking mechanism

A self-locking and assembly technology, applied in pliers, manufacturing tools, etc., can solve problems such as uneven coating of lubricating oil, uneven application of force, loosening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

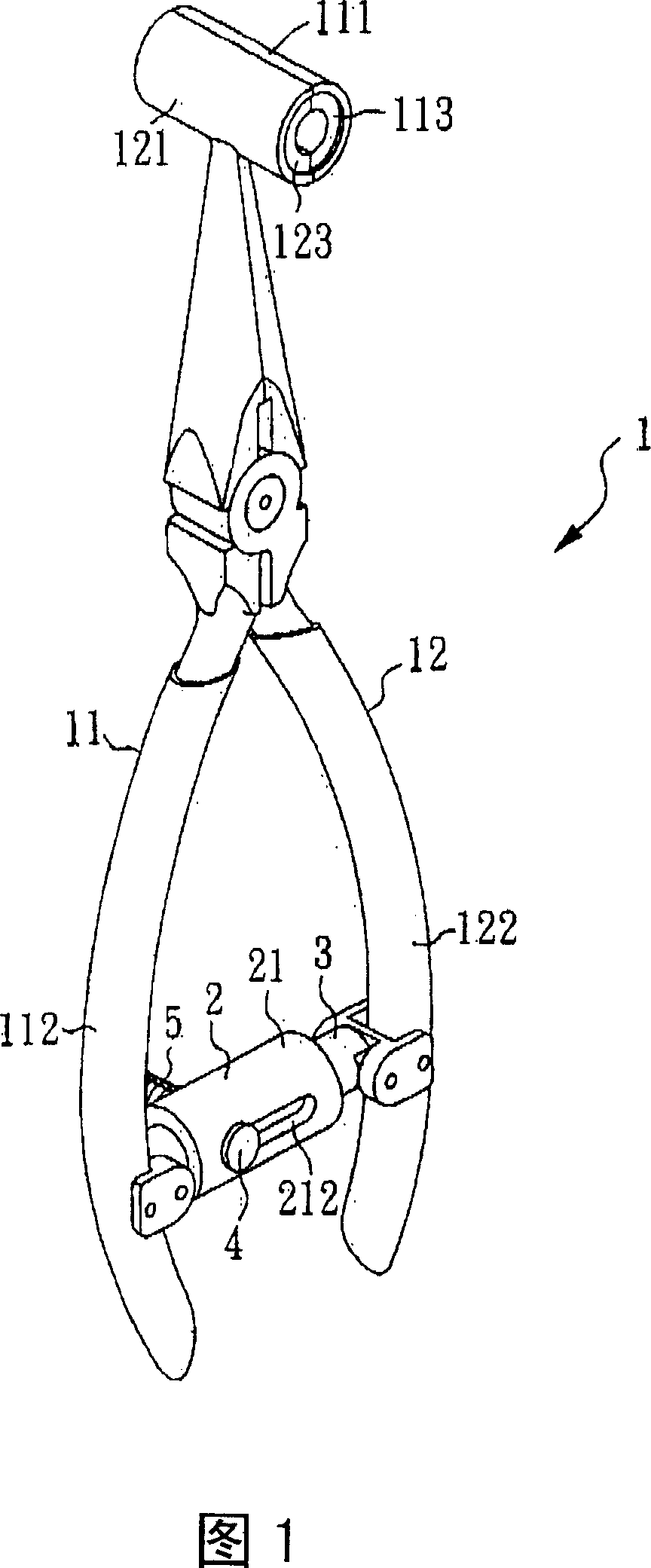

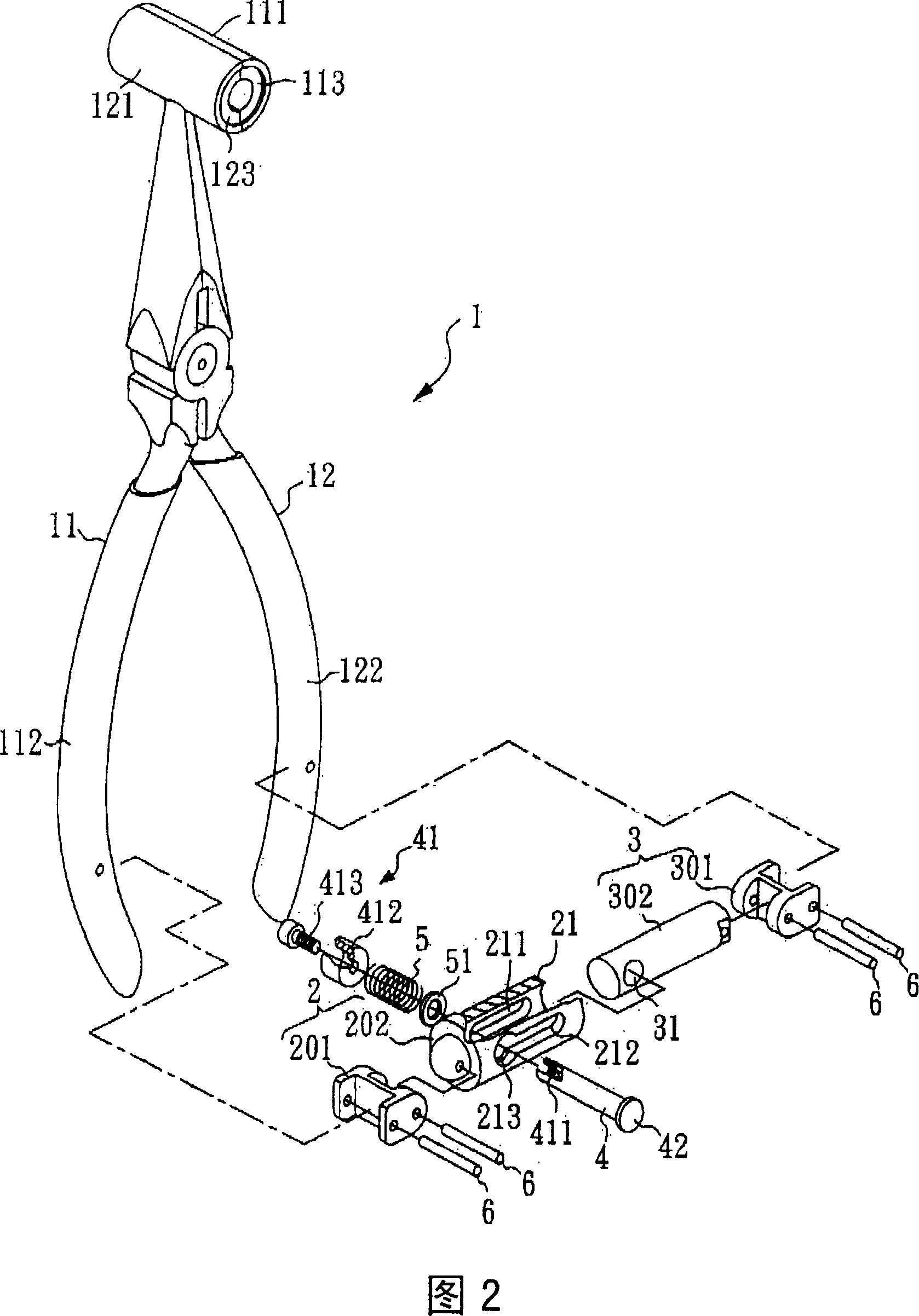

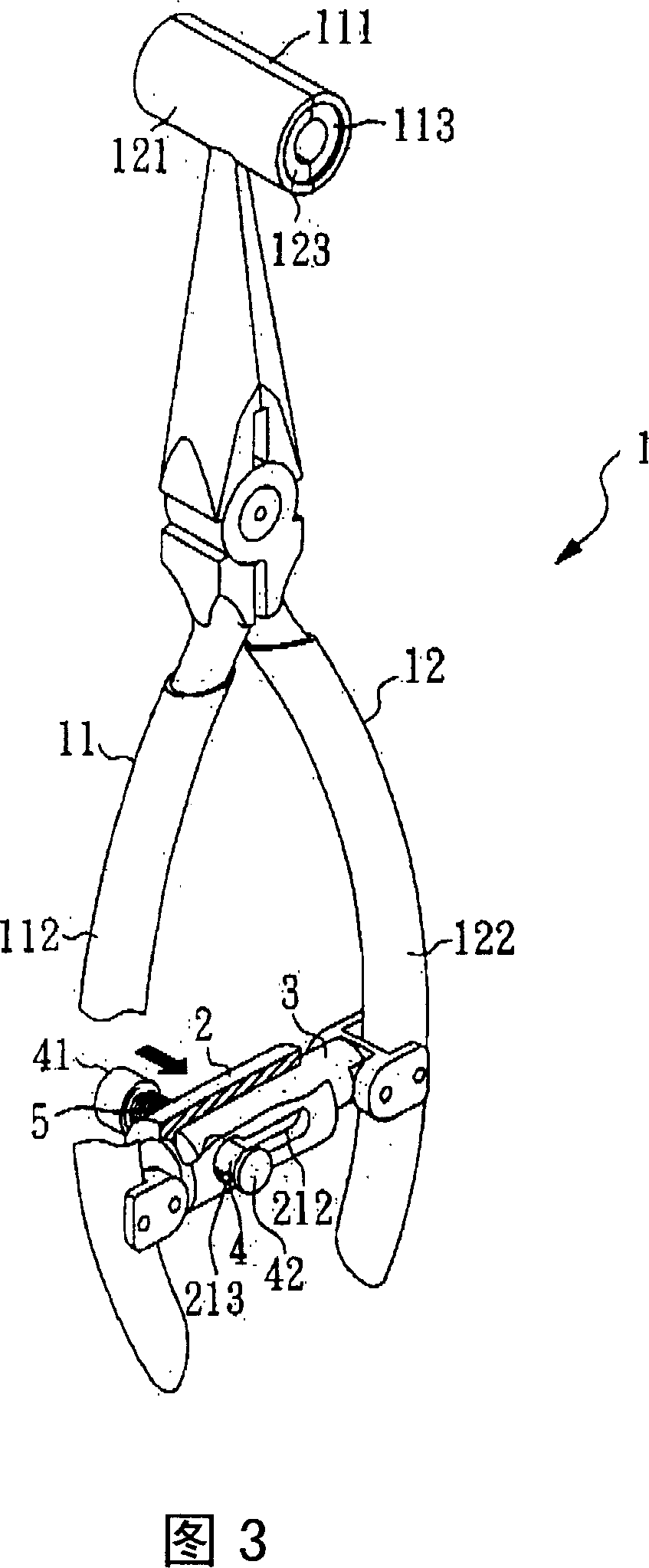

[0022] Please also refer to FIG. 1 which is a perspective view of the present invention and FIG. 2 which is an exploded view of the present invention, wherein a clamp 1 is shown, and this clamp 1 includes a first half clamp 11 and a second half clamp 12, The second clamp half 12 and the first clamp half 11 are intersected and pivoted. Therefore, the first clamp half 11 and the second clamp half 12 can rotate relative to each other, thereby achieving the function of the clamp 1 .

[0023] In addition, a first semicircle 111 is fixed at the front end of the first half clamp 11 of the clamp 1, and a second semicircle 121 is fixed at the front end of the second half clamp 12 of the clamp 1. The second semicircle 121 It is opposite to the first semicircle 111, and a first semicircle rubber cotton 113 is set in the first semicircle 111, and a second semicircle rubber cotton 123 is arranged in the second semicircle 121. Similarly, the second The semicircular rubber sponge 123 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com