A main shaft structure of automatic lubricating and cooling gear shaping machine

An automatic lubrication and cooling technology, which is applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of large force, spindle sleeve locking, insufficient lubrication, etc., and achieve small thermal deformation, The effect of preventing the spindle from grinding and preventing the spindle from being damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

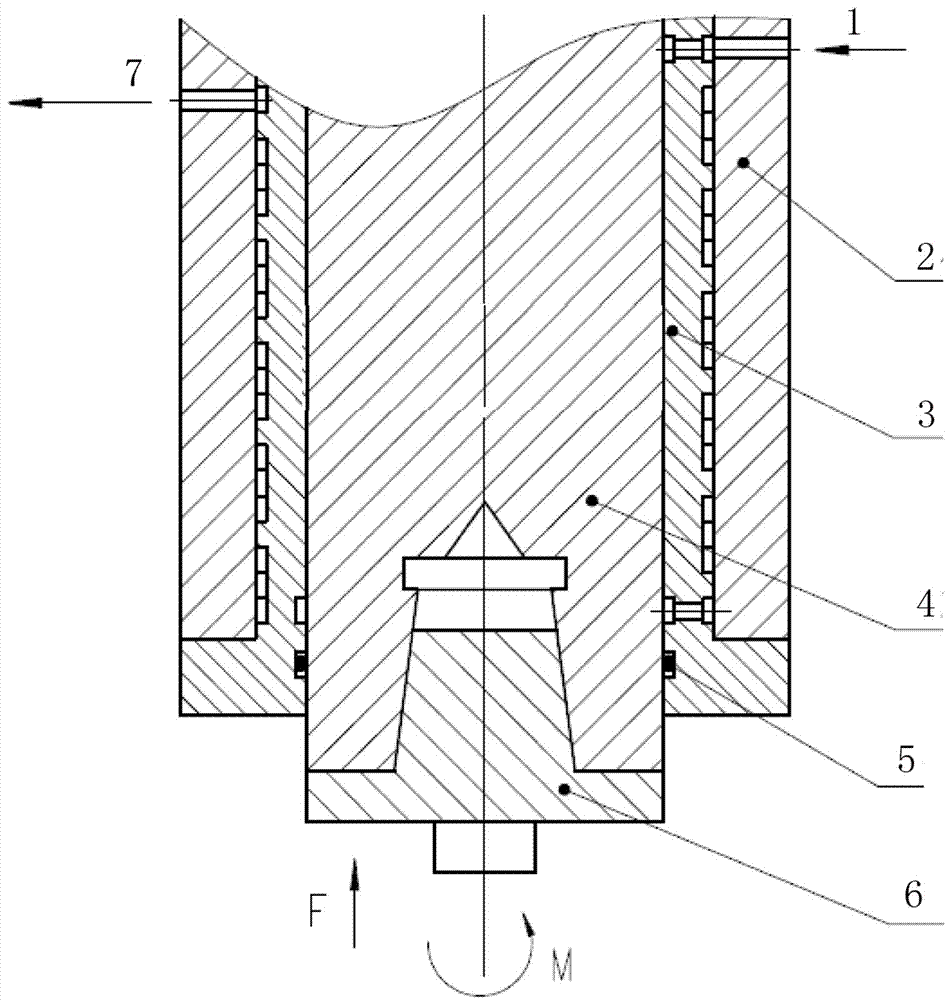

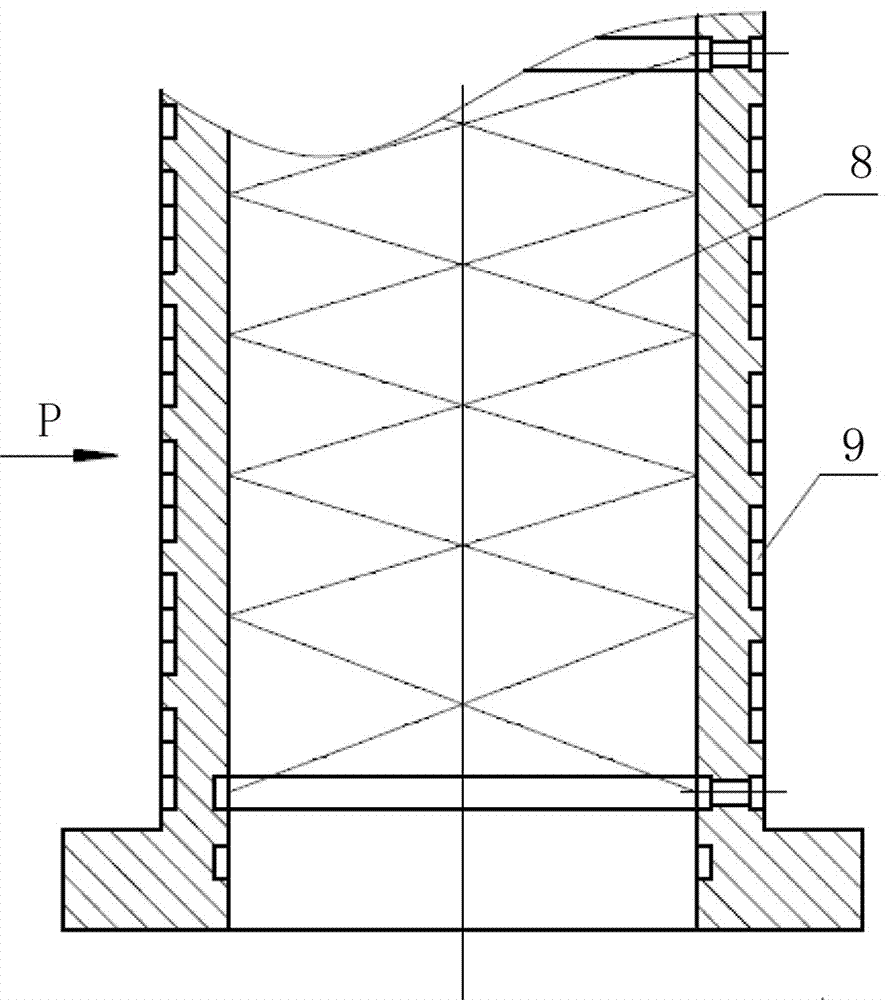

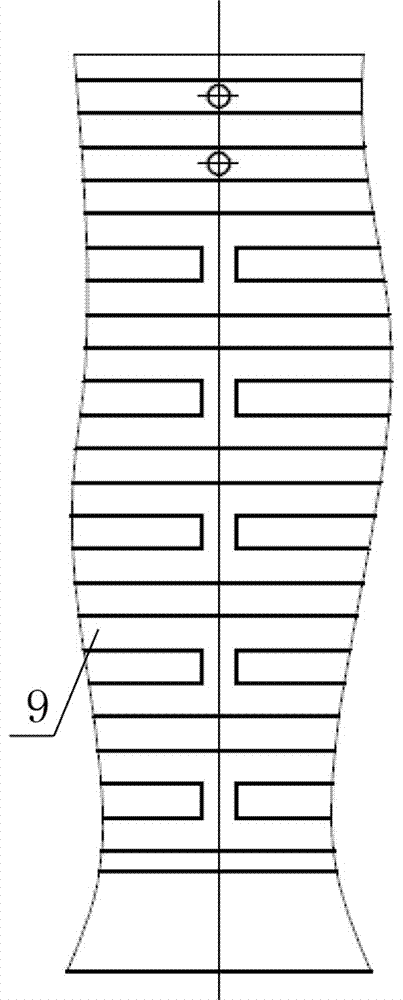

[0014] The structure of the present invention is as figure 1 As shown in -3, an automatic lubricating and cooling type gear shaper spindle structure, which includes a spindle 4, a tool holder 6 is provided at one end of the spindle, a spindle sleeve 3 is arranged outside the spindle 4, and the spindle 4 moves up and down inside the spindle sleeve 3 and rotating movement, the main shaft sleeve 3 is embedded in the tool holder body 2, and the upper end of the main shaft sleeve 3 is respectively provided with an oil inlet 1 and an oil outlet 7, and the main shaft sleeve 3 is provided with a spiral oil groove 8, and the outer circle of the main shaft sleeve 3 There are multiple annular cooling grooves 9, and the lower end of the annular cooling grooves 9 communicates with the spiral oil groove 8. The main shaft 4, the main shaft sleeve 3, the tool holder body 2, the oil inlet 1 and the oil outlet 7 form a closed oil circulation system. There is clearance fit between the main shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com