Glassed steel differential housing

A differential and glass-lined technology, which is applied in the field of glass-lined differential housings, can solve the problems of good high temperature resistance and water permeability, affect transmission, reduce lubrication efficiency, etc., achieve high temperature resistance and water permeability, and reduce the introduction of dander The effect of the probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

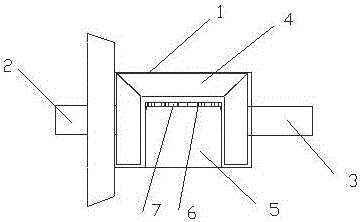

[0011] Such as figure 1 The shown glass-lined differential housing includes a housing 1, and the two sides of the housing 1 are respectively provided with a driving gear 2 and a driven gear 3, and the driving gear 2 and the driven gear 3 are linked through a side gear 4, The housing 1 is provided with a bump 5, the bump 5 is welded in the housing 1, the top of the bump 5 is provided with a top cover 7 with a through hole 6, the top cover 7 is engaged with the bump 5, and the bump 5 The block 5 is cylindrical, and there is a gap between the bump 5 and the driving gear 2, the driven gear 3, and the side gear 4. The gap is not more than 1 cm. The distance between the through holes 6 on the top cover 7 is determined by the two sides Decreasing toward the center, wherein, the outer layer of the casing 1 is coated with a layer of glass lining.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com