Electrical servo alignment control system and control method for lithography machine

A technology of control system and lithography machine, applied in the direction of micro-lithography exposure equipment, photolithography process exposure device, etc., can solve problems such as thermal deformation of lithography machine workbench, improve steady-state control accuracy, ensure normal operation, Achieving Precisely Controlled Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

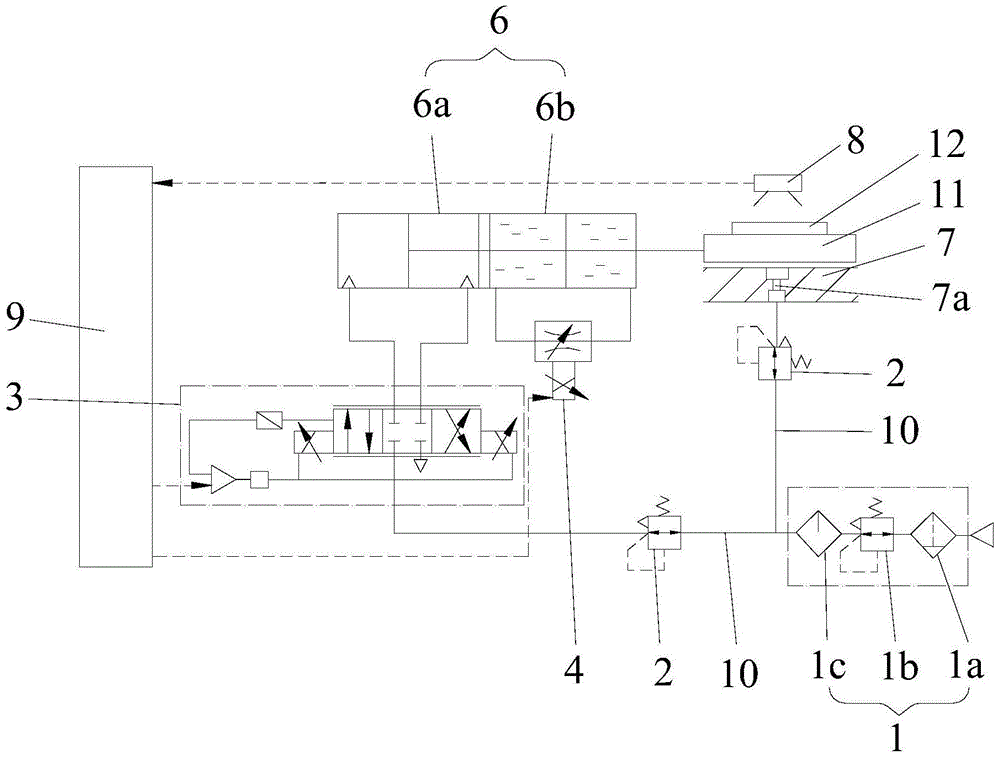

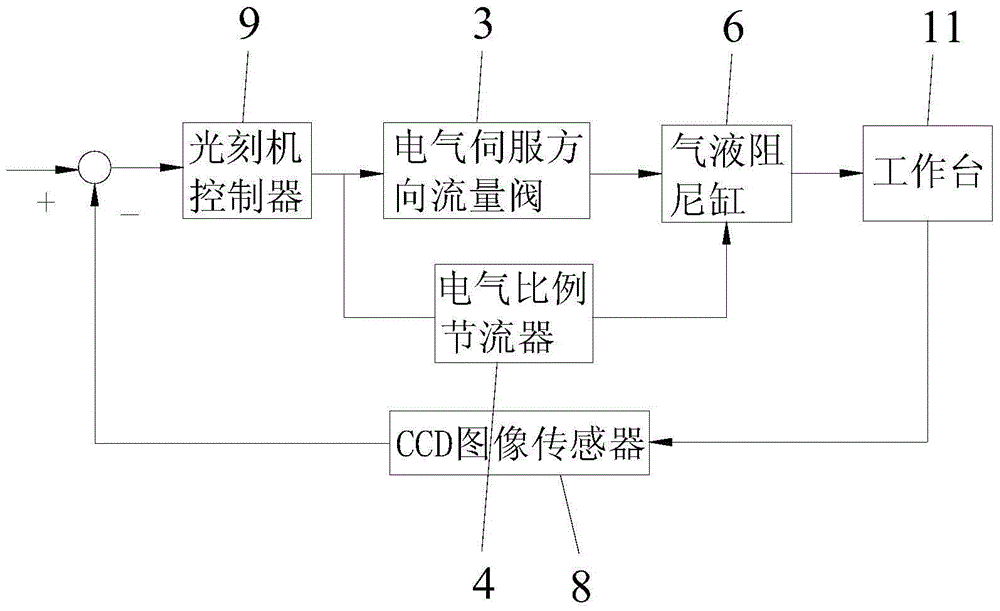

[0020] Please refer to Figure 1-2 , the electrical servo alignment control system of the lithography machine includes a pneumatic triple piece 1, two first pressure reducing valves 2, an electrical servo directional flow valve 3, an electrical proportional throttle 4, a gas-liquid damping cylinder 6, a static pressure Air bearing guide rail 7, CCD image sensor 8 and lithography machine controller 9.

[0021] The pneumatic triple unit 1 includes a water separation filter 1a, a second pressure reducing valve 1b and a lubricator 1c connected in sequence, the water separation filter 1a is connected to an air source, and the lubricator 1c is connected to the 10 of the two pipes.

[0022] The two first pressure reducing valves 2 are respectively arranged on the two pipelines 10, and are used to control the outlet pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com