High-precision worm and gear transmission mechanism

A technology of worm gear and transmission mechanism, which is applied in the direction of gear transmission, transmission, mechanical equipment, etc., can solve the problems of inconvenient worm synchronous drive function, inconvenient worm gear derivation work, and unfavorable intermittent regulation, etc., and achieves the phenomenon of intermittent regulation. , The effect of easy derivation work and smooth synchronous rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

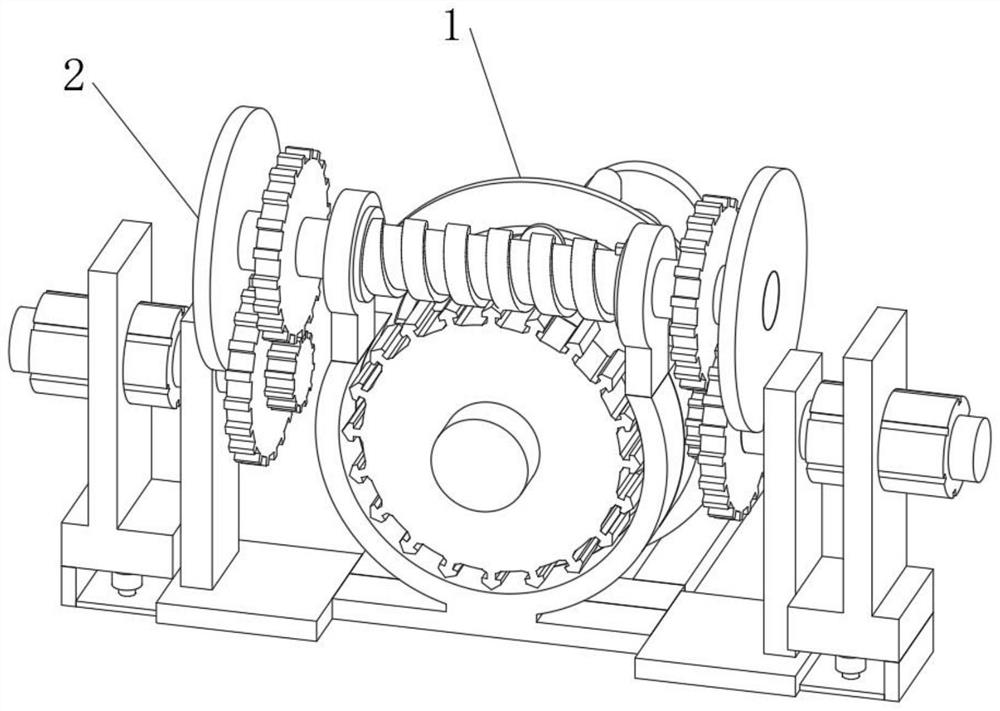

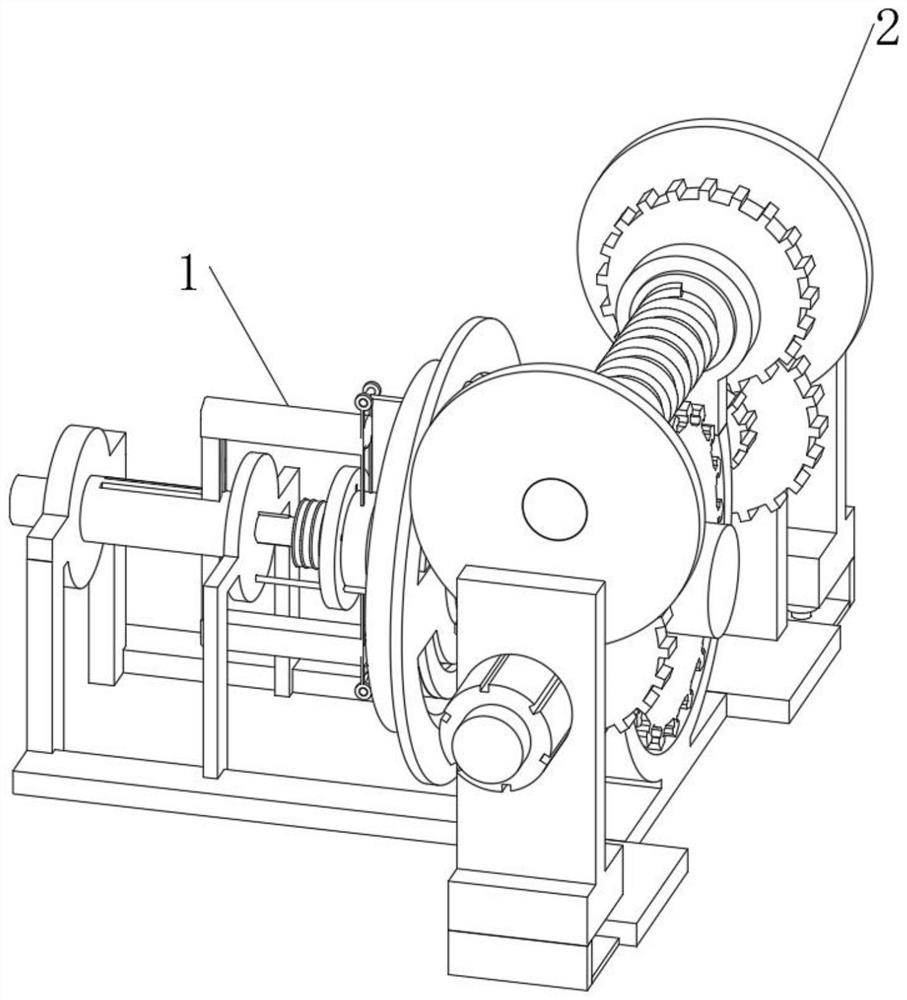

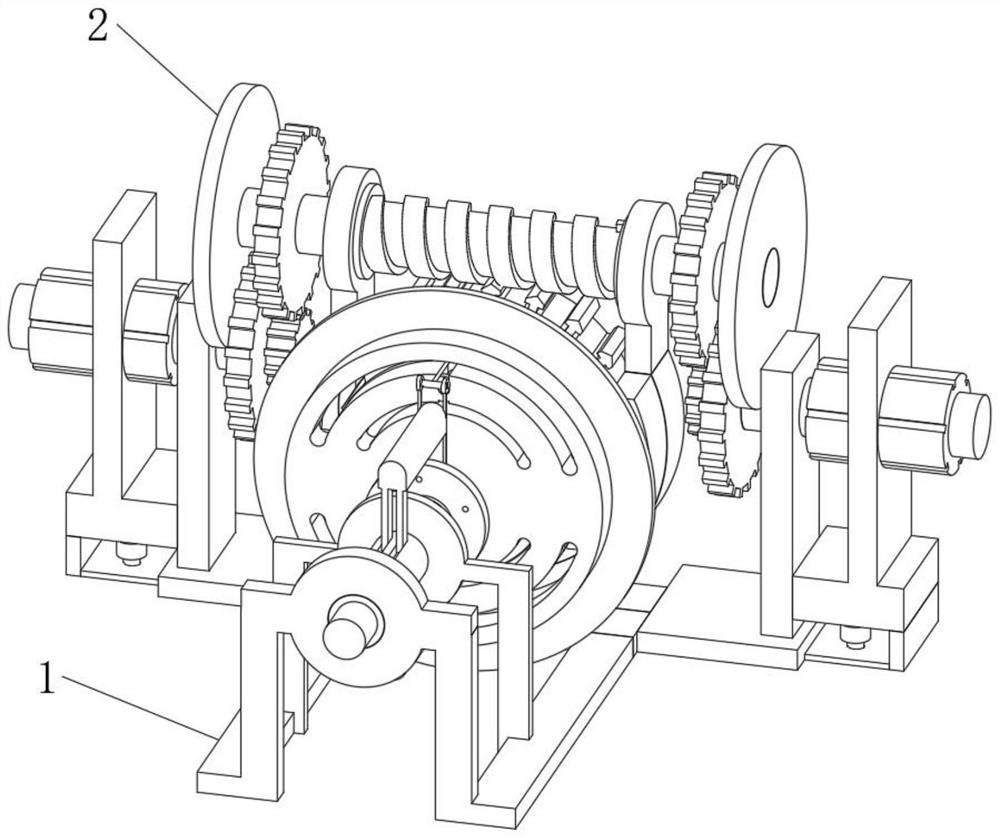

[0040] see figure 1 , figure 2 , image 3 , an embodiment provided by the present invention: a high-precision worm gear and worm drive mechanism, including a worm gear derivation connecting structure 1 and a worm connecting driving structure 2, and a worm connecting driving structure 2 is meshed and connected at the center front end of the worm gear derivation connecting structure 1 , through the combined connection of the worm gear derivation connection structure 1 and the worm connection drive structure 2, it is convenient for the integrated combination, which is helpful for the cooperative driving work;

[0041] see Figure 4 The worm gear derivation connection structure 1 includes a derivation transfer part 3 and a first support stand 4, the derivation and transfer part 3 is arranged at the central position of the worm gear derivation connection structure 1, and the rear end of the derivation transfer part 3 is in phase with the first support stand 4 The socket setting...

Embodiment 2

[0048] On the basis of Example 1, as Figure 8 As shown, the bottom side end of the worm connection drive structure 2 is communicated with a matching grooved pipe 29, the front end of the matching grooved pipe 29 is communicated with an oil feed pipe 28, and the front end of the oil feed pipe 28 is communicated with a communication pipe 27.

[0049] During the implementation of this embodiment, the user can communicate with the worm connection drive structure 2 by installing the communication pipe 27 , the oil supply pipe 28 and the matching groove pipe 29 , and the setting of the communication pipe 27 , the oil supply pipe 28 and the matching groove pipe 29 , and The bottom position of the communication pipe 27 is communicated with the outside world, which facilitates the oil supply work, realizes the internal lubrication work, and better reduces the internal resistance. For the purpose of lubrication, the communication pipe 27, the oil supply pipe 28, and the matching groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com