A kind of automatic continuous electroplating method

A vertical continuous electroplating and automatic technology, applied in the directions of printed circuits, electrical components, printed circuit manufacturing, etc., can solve the problems of easy scratches on the PCB board, oxidation of the PCB board, lowering the yield of finished products, etc., to save manpower and material resources, Guaranteed quality and simple work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

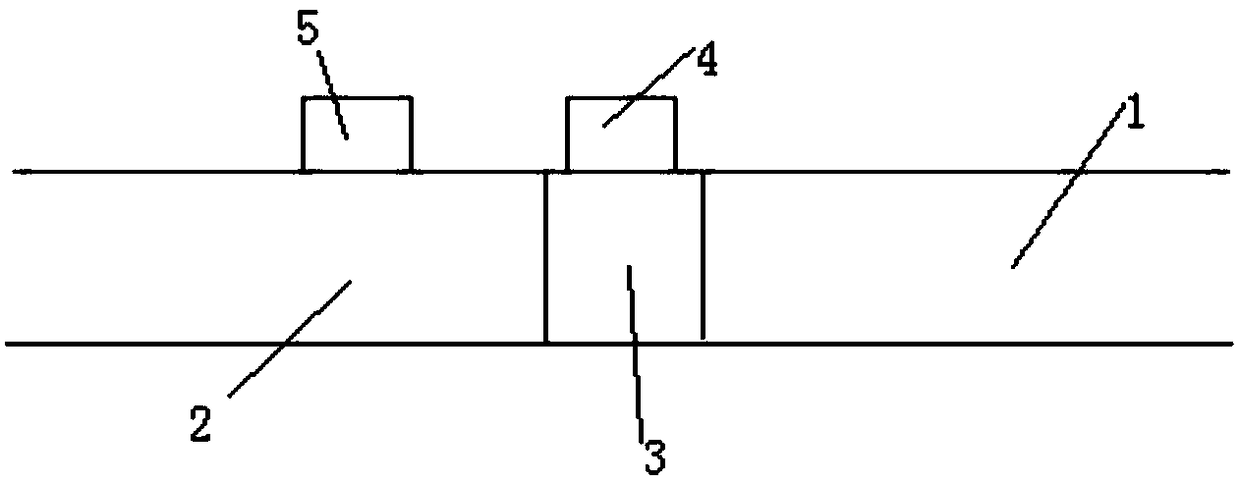

[0014] Refer to attached figure 1 , this embodiment includes a horizontal sinking copper wire 1 and a vertical continuous electroplating line 2, an integrated machine 3 for receiving and releasing boards is provided between the horizontal sinking copper wire 1 and the vertical continuous plating line 2, and an accompanying plating is provided on the side of the vertical continuous plating line 2 The board temporary storage device 5, the side of the retractable board integrated machine 3 is provided with a retractable board temporary storage device 4, the control signal of the horizontal sinking copper wire 1 is connected with the control signal of the vertical continuous electroplating line 2, and the transmission of the horizontal sinking copper wire 1 The speed is the same as the conveying speed debugging of the vertical continuous electroplating line 2, and the same conveying speed is locked when the horizontal copper sinking wire 1 and the vertical continuous plating line 2...

Embodiment 2

[0022] Refer to attached figure 1 , The difference between this embodiment and Embodiment 1 is that the horizontal copper sinking wire 1 and the vertical continuous electroplating line 2 are debugged with the same conveying speed of 2.5m / min; the rest are basically the same as Embodiment 1.

[0023] The entire production line is connected, eliminating the intermediate transfer process, greatly improving work efficiency, saving manpower and material resources, reducing production costs, avoiding scratches caused by transfer transfer, effectively ensuring the quality of finished products, and will not cause waste of production capacity. The operation is stable and can Avoid the loss caused by production failure, reduce the loss of the production line, and prolong the service life of the production line.

Embodiment 3

[0025] Refer to attached figure 1 , The difference between this embodiment and Embodiment 1 is that the horizontal copper sinking wire 1 and the vertical continuous electroplating wire 2 are debugged with the same conveying speed of 1.5m / min; the rest are basically the same as Embodiment 1.

[0026] The entire production line is connected, eliminating the intermediate transfer process, greatly improving work efficiency, saving manpower and material resources, reducing production costs, avoiding scratches caused by transfer transfer, effectively ensuring the quality of finished products, and will not cause waste of production capacity. The operation is stable and can Avoid the loss caused by production failure, reduce the loss of the production line, and prolong the service life of the production line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com