A double-layer steel plate composite shear wall with truss-type ties of channel members

A steel plate shear wall and combined shear wall technology, which is applied to walls, building components, buildings, etc., can solve the problems of large overall area of the shear wall, loss of bearing capacity, and difficulty in mass production and application, so as to improve economic efficiency, Improve the integrity and strengthen the effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the embodiment of this patent is described in detail.

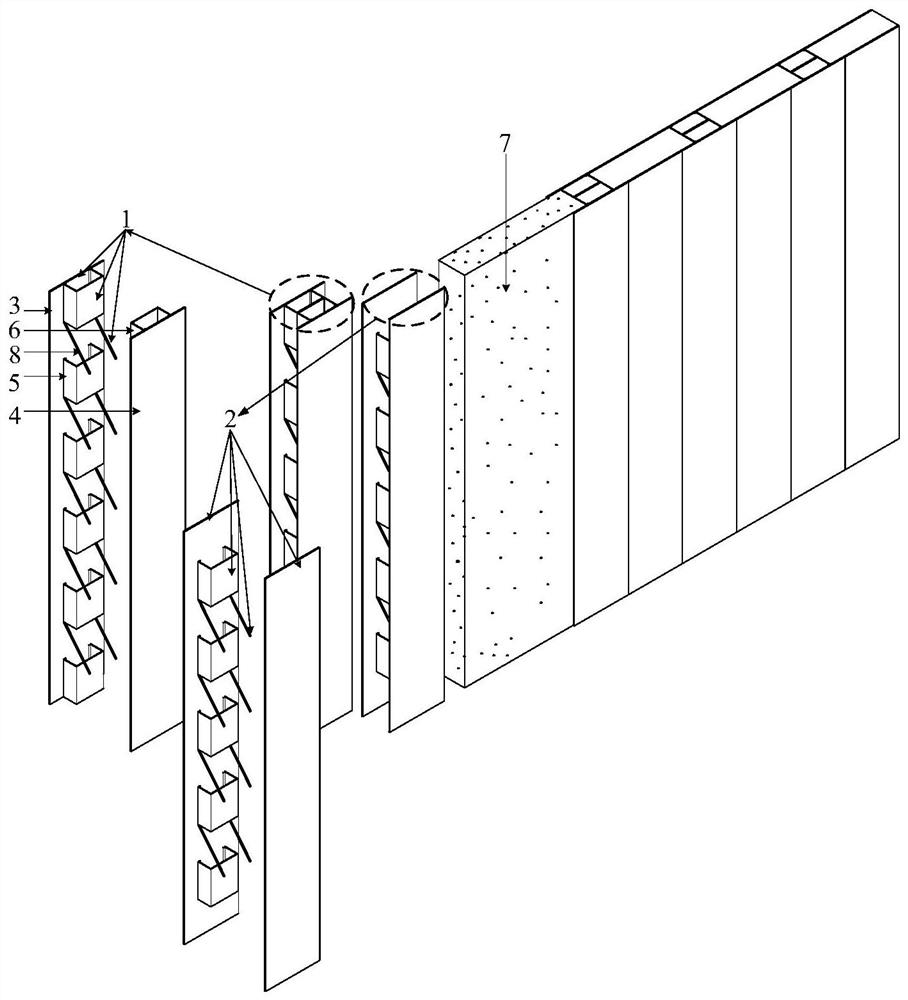

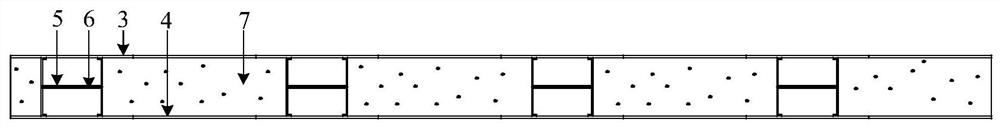

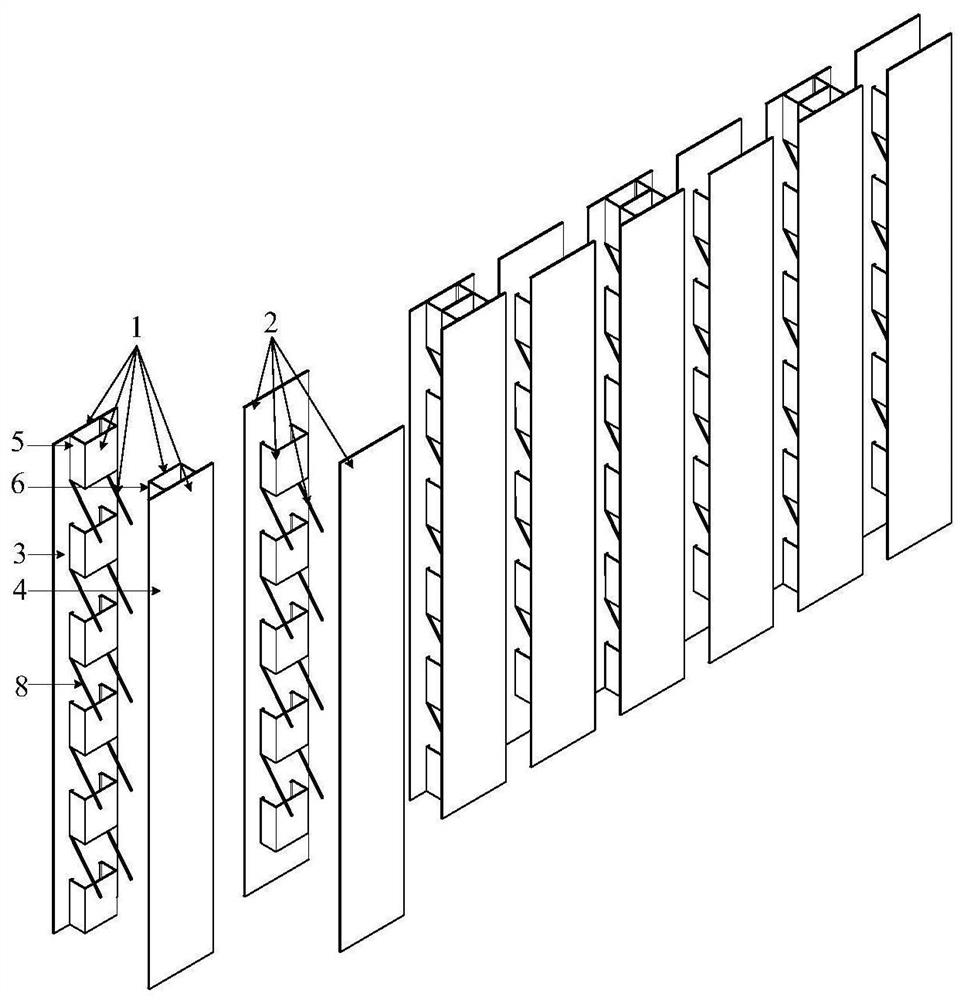

[0025] like Figure 1~6 As shown, a double-layer steel plate composite shear wall with truss-type ties

[0026] Include the following components.

[0027] 1——Steel plate shear wall unit one;

[0028] 2——Steel plate shear wall unit 2;

[0029] 3——outer steel plate one;

[0030] 4——outer steel plate two;

[0031] 5——Trough piece one;

[0032] 6——Trough part two;

[0033] 7 - concrete;

[0034] 8 - tie rod.

[0035] like Figure 1~6As shown, a double-layer steel plate composite shear wall with truss-type ties of channel parts is characterized in that: the composite shear wall is composed of several steel plate shear wall units-1 with channel parts and the same number of strips The steel plate shear wall unit 2 of the trough-shaped part is composed of a double-layer steel plate shear wall formed by cross welding and integrally poured concrete 7; the steel plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com