Batten plate constraint type I-shaped steel bone confined concrete column and fabrication method thereof

A technology for constraining concrete and I-shape, applied in the directions of columns, piers, pillars, etc., can solve problems such as the decrease of bearing capacity of steel-concrete columns, the decrease of concrete restraint capacity, buckling deformation, etc. The effect of high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

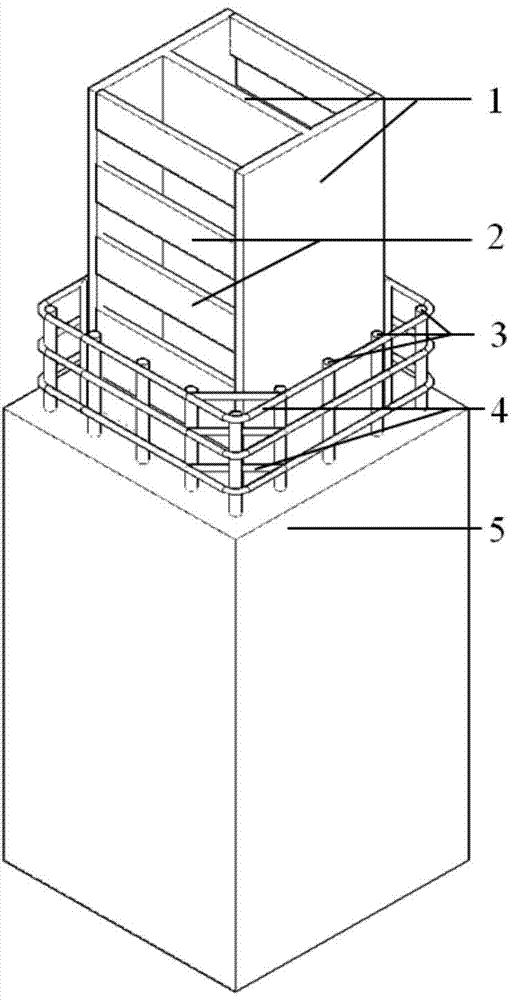

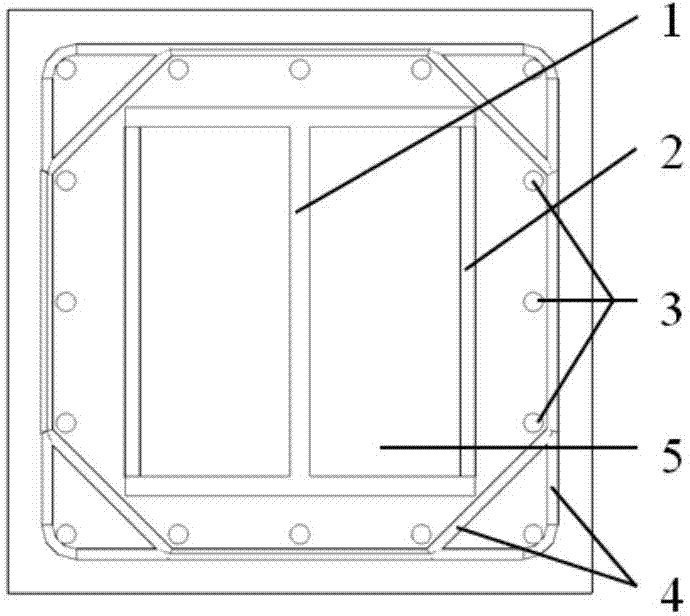

[0028] Such as figure 1 , figure 2 As shown in Fig. 1, the panel-constrained I-shaped steel-reinforced concrete column includes I-shaped steel frame 1, constrained panel 2, longitudinal steel bar 3, composite stirrup 4, and concrete 5; On the basis of the addition of restraint plate formation.

[0029] According to the technical solution of the present invention, the manufacturing steps of the panel-constrained I-shaped steel frame-constrained concrete column are as follows:

[0030] 1) Factory prefabricated welded I-shaped steel frame 1;

[0031] 2) Position the restraint plate 2 and weld it to the flange of the I-shaped steel frame 1;

[0032] 3) After the prefabricated and welded steel frame members are transported to the site and positioned, the longitudinal reinforcement 3 and the composite stirrup 4 are bound;

[0033] 4) Support the formwork and pour concrete 5 for maintenance;

[0034] 5) When the concrete reaches its strength, form a plate-bound I-shaped steel f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com