Patents

Literature

68 results about "Elastic plastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastic deformation results in the permanent change in an object's shape or size because of the pressure applied on it, which cannot be reversed even after this pressure is removed. Elastic deformation involves a temporary change in an object's shape or size, which self-reverses after force is no longer exerted on it.

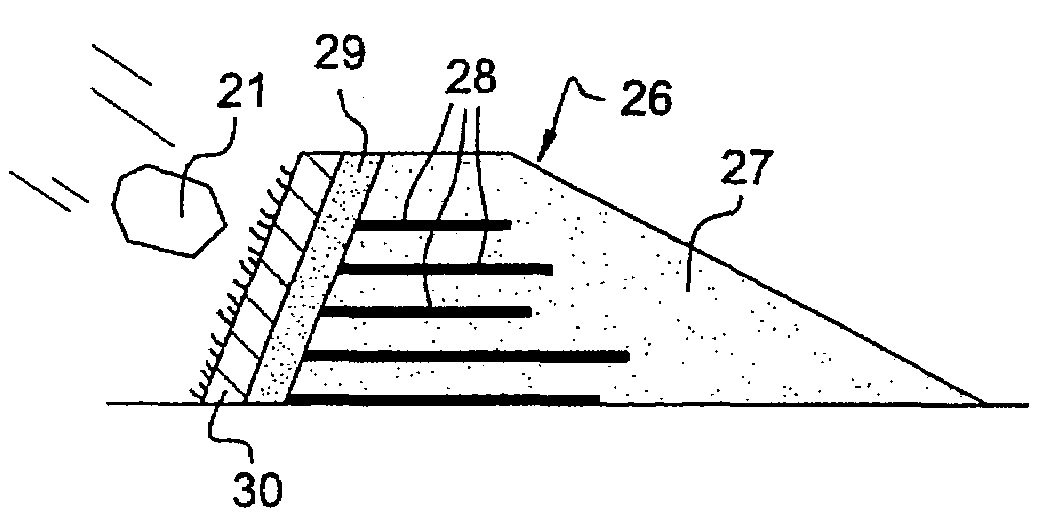

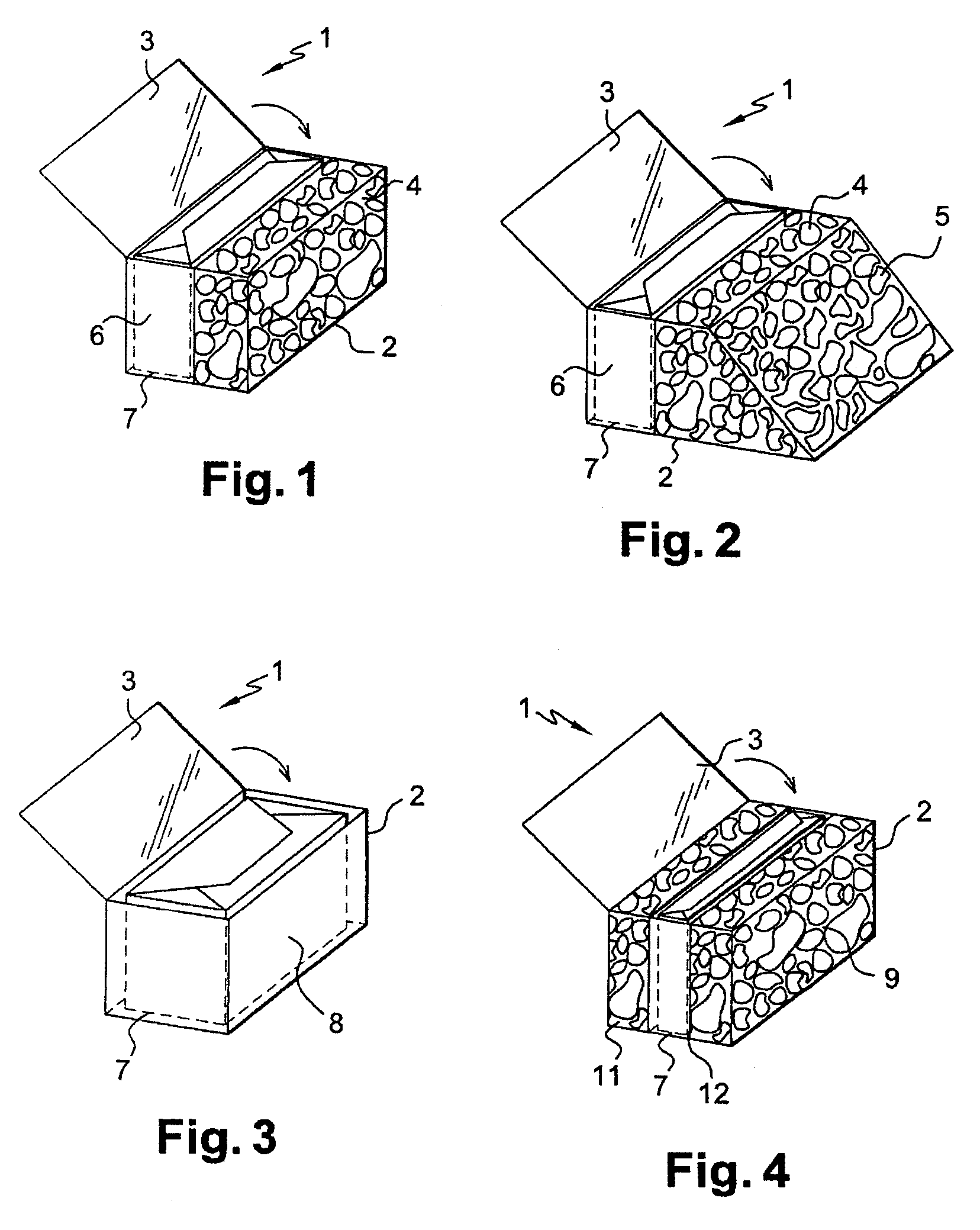

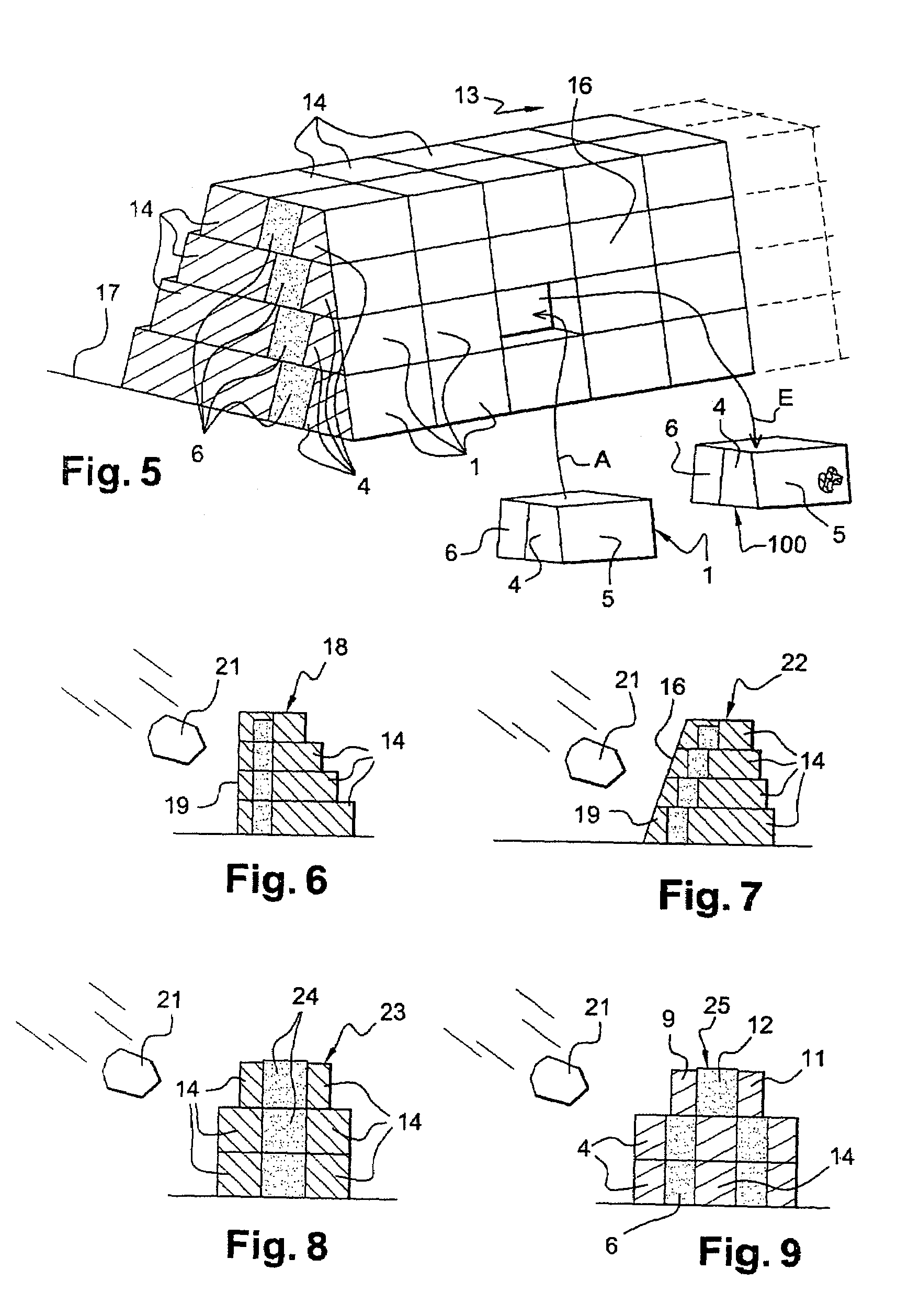

Civil engineering structure, individual construction element and method for reinforcing such a structure

InactiveUS7425107B2Artificial islandsProtective constructionEngineering structuresElastic plastic deformation

A civil engineering structure, intended for ensuring protection against impacts of moveable masses, has a face exposed to the impacts of moveable masses. The structure includes, in the region of the face exposed to the impacts of moveable masses, a set of individual construction elements secured to one another and filled completely or partially with at least one material having a capacity for being deformed elastoplastically, the individual construction elements liable to be damaged by impacts of moveable masses being capable of being replaced individually by similar individual construction elements.

Owner:FRANCE GABION ZONE IND

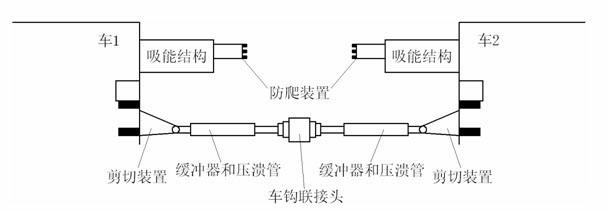

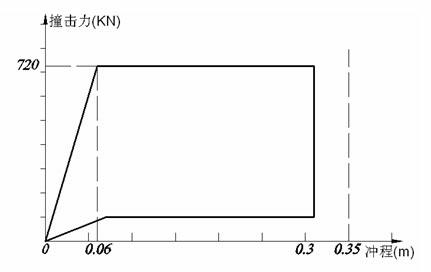

Complete automobile collision simulation method on basis of parameterization design

InactiveCN102339350AReduce computational complexitySpecial data processing applicationsCollision dynamicsEngineering

The invention relates to a complete automobile collision simulation method on the basis of the parameterization design and belongs to the field of a nonlinear finite element and nonlinear multi-body dynamics. The method comprises the following steps of: calculating collision force and a stroke of each power-absorbing component by nonlinear finite element software; according to series / parallel power-absorbing characteristics of the power-absorbing components, determining an equivalent total rigidity of power adsorption devices between carriages; then establishing a complete automobile collision dynamic performance analysis model on the basis of the parameterization design; and combining the complete automobile collision dynamic performance analysis model with constraint conditions to obtain an optimal combination of the power-absorbing characteristics of the power-absorbing components so as to obtain the optimal values of motion and a longitudinal load of each carriage in the complete automobile collision process. In the method, the nonlinear finite element and the nonlinear multi-body dynamics are combined to carry out complete automobile collision simulation research; the nonlinearity and the elastic plastic deformation of a material are simulated by the established model; and meanwhile, the collision simulation analysis of an automobile head is expanded to the complete automobile.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

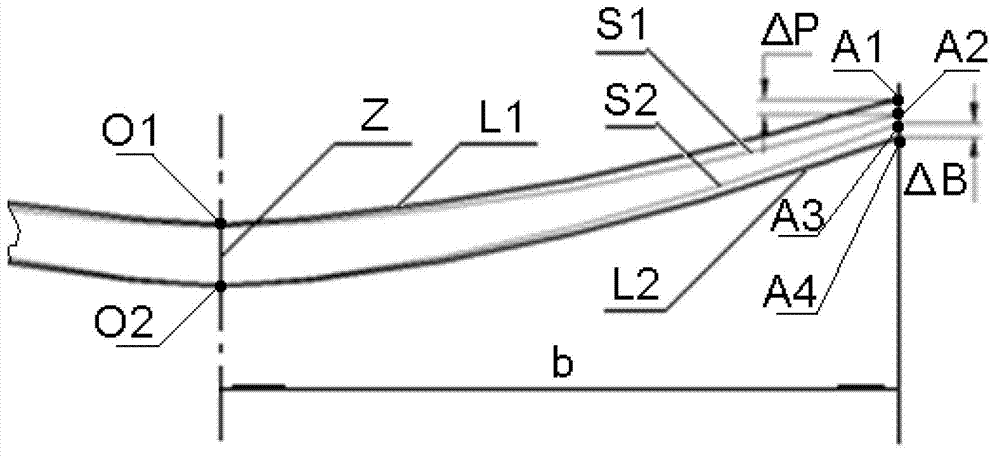

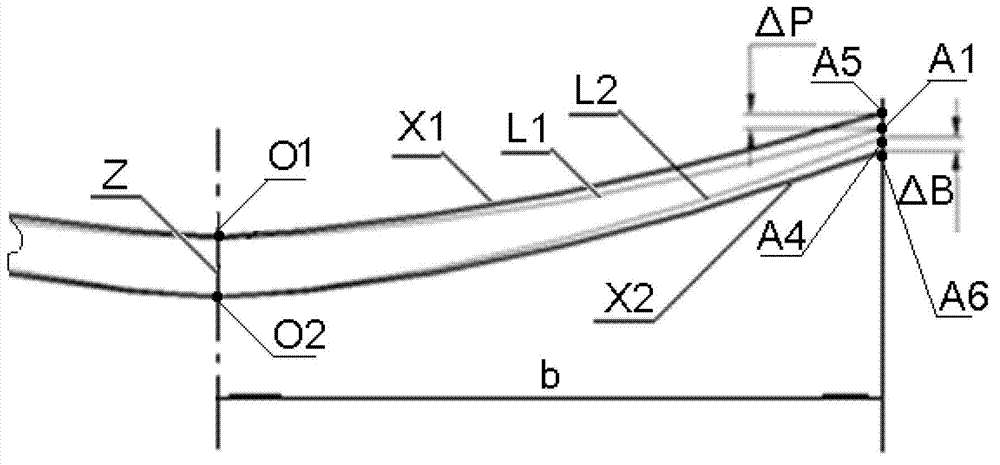

Precision forging blade thickness plastic deformation compensation method

ActiveCN103244195AReduce the frequency of clampingShorten the manufacturing cycleBlade accessoriesMachines/enginesAviationManufacturing technology

The invention belongs to manufacturing technologies for aviation engine blade precision forging dies and relates to a precision forging blade thickness plastic deformation compensation method. The compensation method is characterized by comprising a step (1.1) of determining maximum compensation values delta P0 and delta B0 according to elastic-plastic deformation characteristics of a blade, a step (1.2) of determining a blade basin compensation molded line X1, a step (1.3) of determining a blade back compensation molded line X2, a step (1.4) of determining first-time trial forging maximum compensation values delta P1 and delta B1, and repeating the step (1.2) to the step (1.4) until two maximum compensation values are no greater than 0.01mm. According to the precision forging blade thickness plastic deformation compensation method, pliers maintenance times of a precision forging die is greatly reduced, a manufacturing cycle of the precision forging die is shortened, and working efficiency is improved.

Owner:AECC AVIATION POWER CO LTD

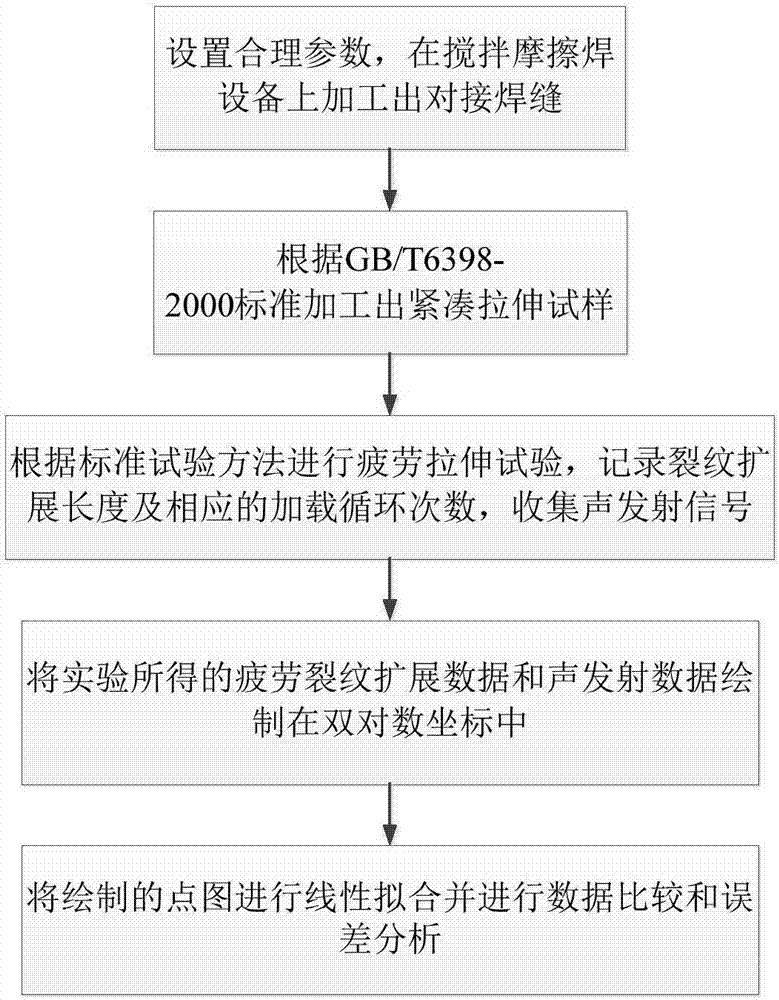

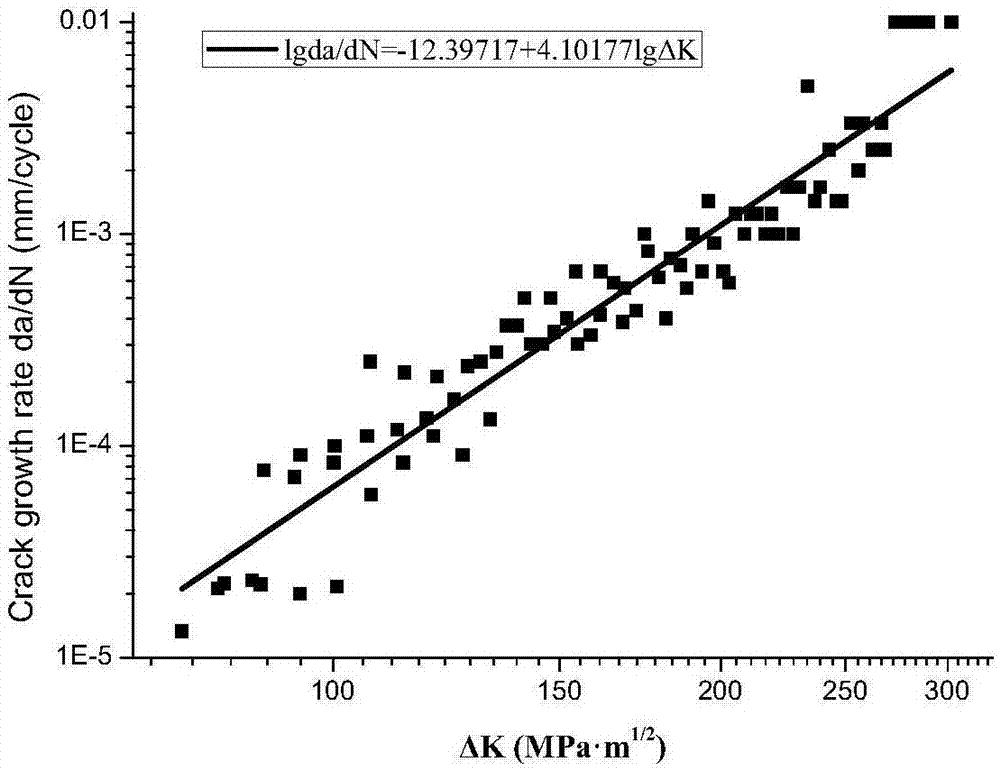

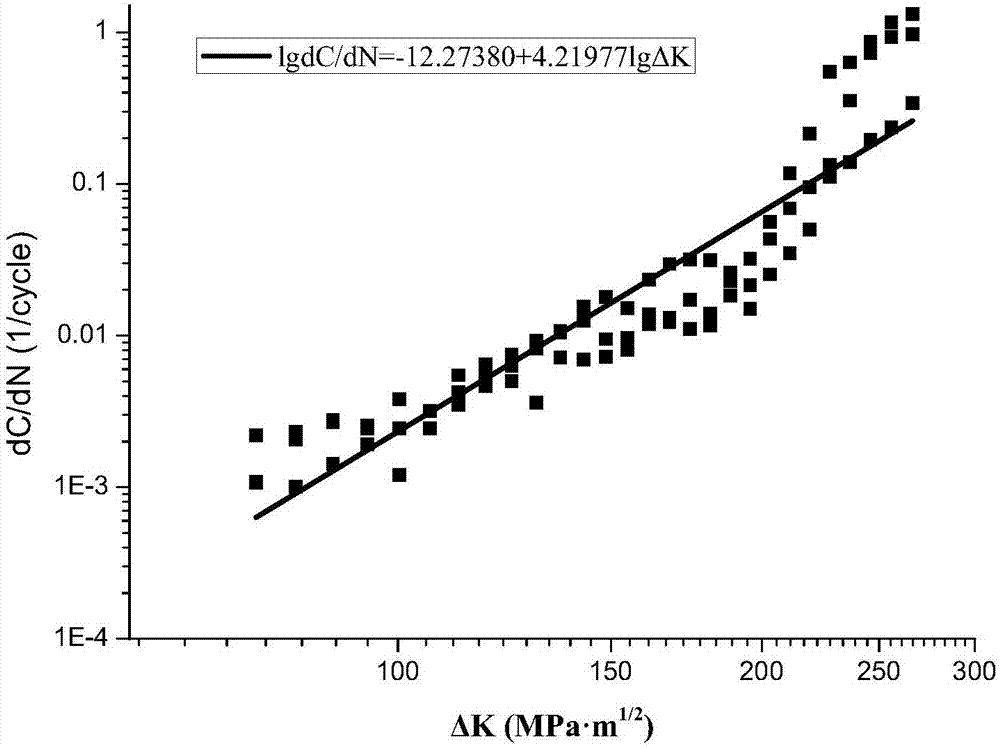

Acoustic emission inspection based research method for expanding characteristics of fatigue cracks of magnesium alloy stir-friction welding head

InactiveCN106872300AThe testing process is simpleThe test result is accurateMaterial analysis using acoustic emission techniquesMaterial strength using repeated/pulsating forcesFatigue loadingCurve shape

The invention discloses an acoustic emission inspection based research method for expanding characteristics of fatigue cracks of a magnesium alloy stir-friction welding head, and belongs to the technical field of mechanical properties of the magnesium alloy materials. The method is characterized in that in a process of expanding a test piece under action of fatigue load for a precrack-containing magnesium alloy, internal energy of the test piece is increased as a result of an elastic-plastic deformation effect, and finally, the energy is released while the cracks expand to obtain a relationship curve between an internal acoustic emission signal of the test piece and circulating times; the expansion condition of the fatigue test piece is determined by analyzing curve shape features, so that the critical value when the magnesium alloy enters an unstable propagation stage is obtained. The method does not require an experimenter to observe the test piece all the time, and has the advantages of being convenient, quick, accurate and the like.

Owner:TAIYUAN UNIV OF TECH

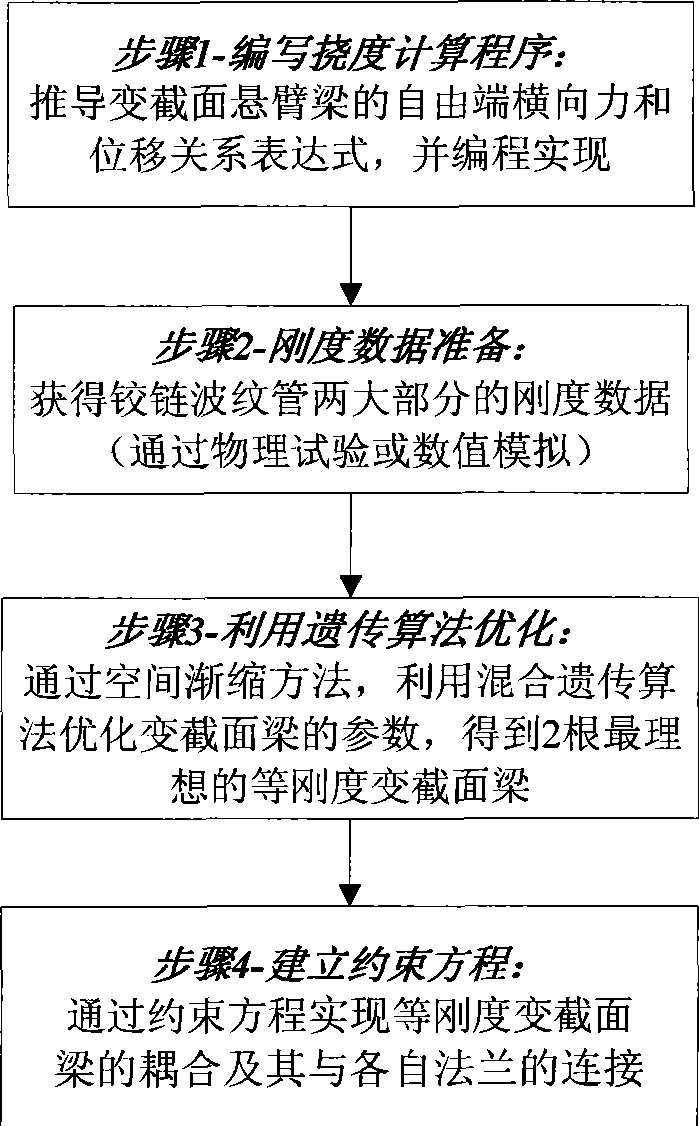

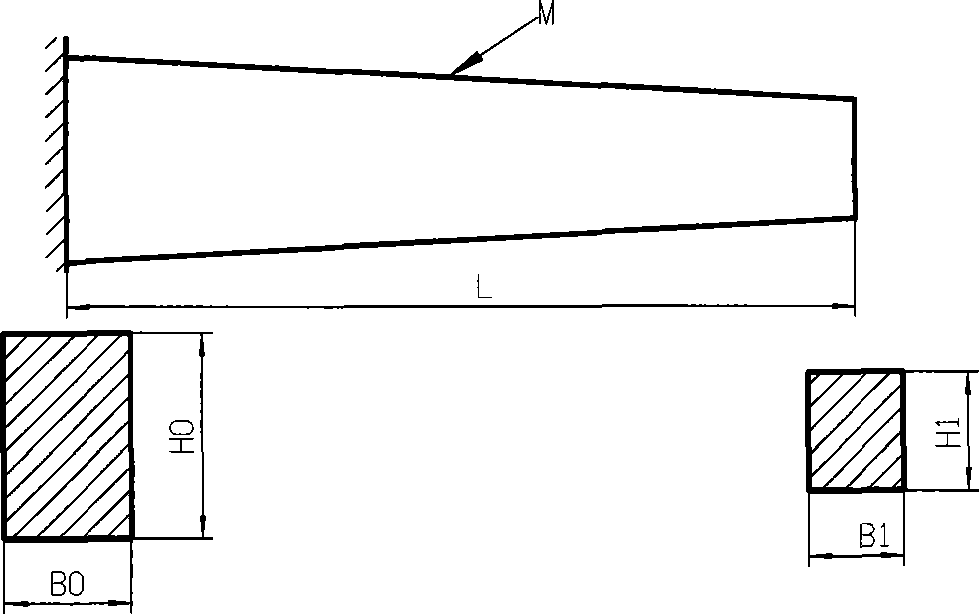

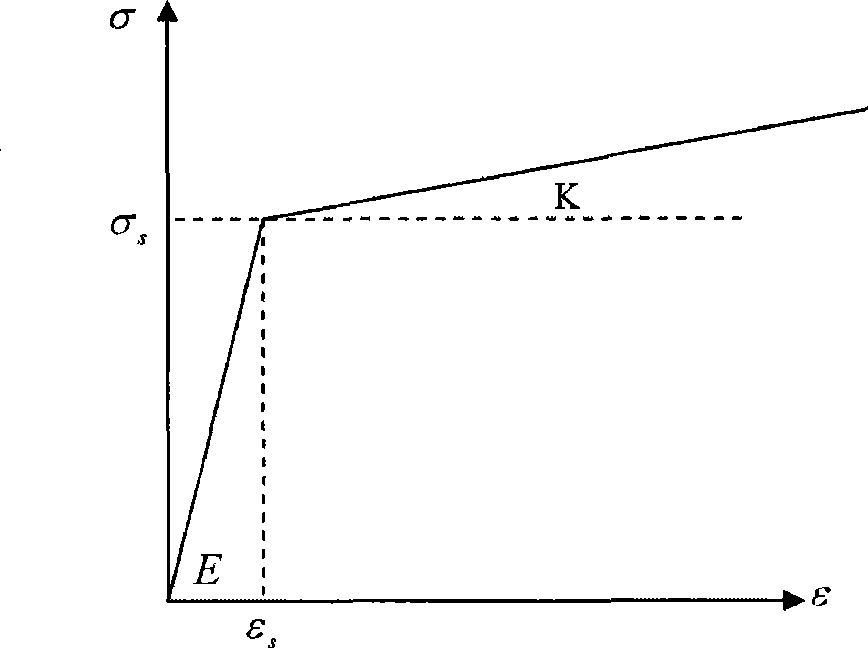

Method for equivalence hinged corrugated pipe by coupled variable cross-section beam

InactiveCN101520814ASolve the difficult problem of finite element calculation and debuggingSolve the problem of difficult calculation and debuggingSpecial data processing applicationsCircular discSystems design

The invention relates to a design method for the equivalence a hinged corrugated pipe by coupled variable cross-section beams in order to simplify the finite element analysis work for the complicated pipeline system design of the hinged corrugated pipe. Firstly, deducing the relation between force and displacement when transversal force is exerted on the free end of either variable cross-section beam of which any interface is rectangular based on the assumption that a cantilever beam has small deflection, and considering the elasticity and the elastic plastic deformation of either variable cross-section beam; secondly, proposing a method of simplifying a hinged corrugated pipe model and a method of utilizing finite element calculation to obtain the rigidity data of the fixed part of the simplified hinged corrugated pipe in two directions; thirdly, proposing a method of utilizing a mixing genetic algorithm to optimize parameters of the variable cross-section beams and proposing a special gradual shrinkage method aiming at the mixing genetic algorithm so as to further obtain geometric parameters and material parameters of the two variable cross-section beams; and finally, coupling the two variable cross-section beams at the free ends by constraint equations and connecting the roots of the variable cross-section beams with flanges by establishing auxiliary discs.

Owner:TSINGHUA UNIV

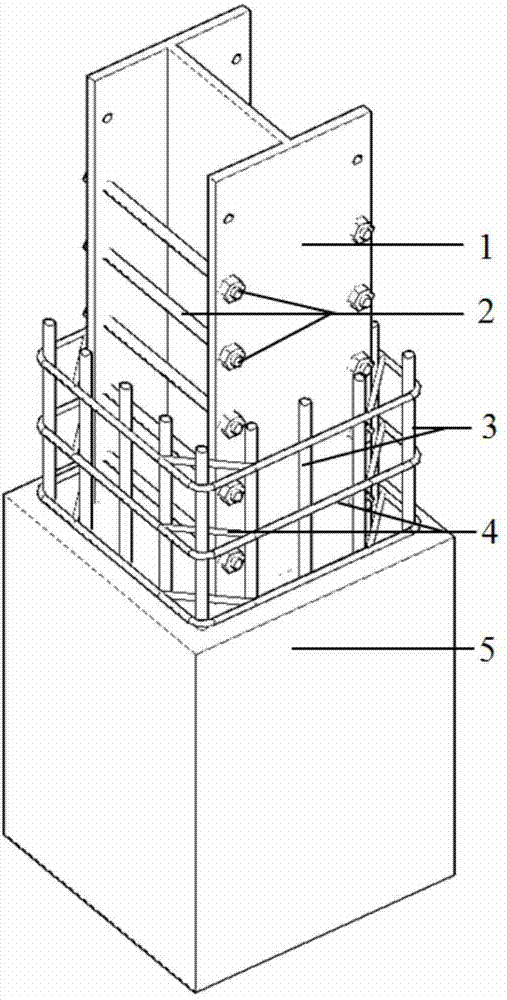

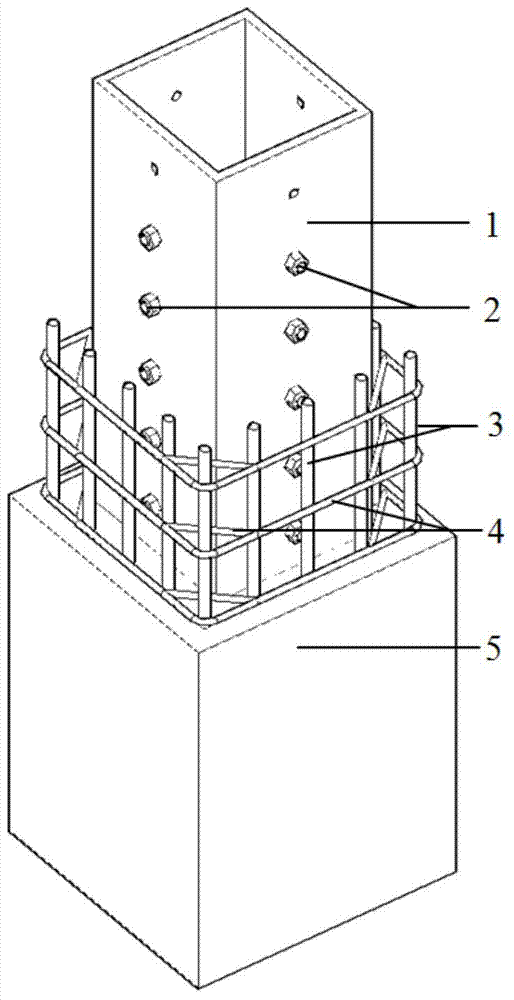

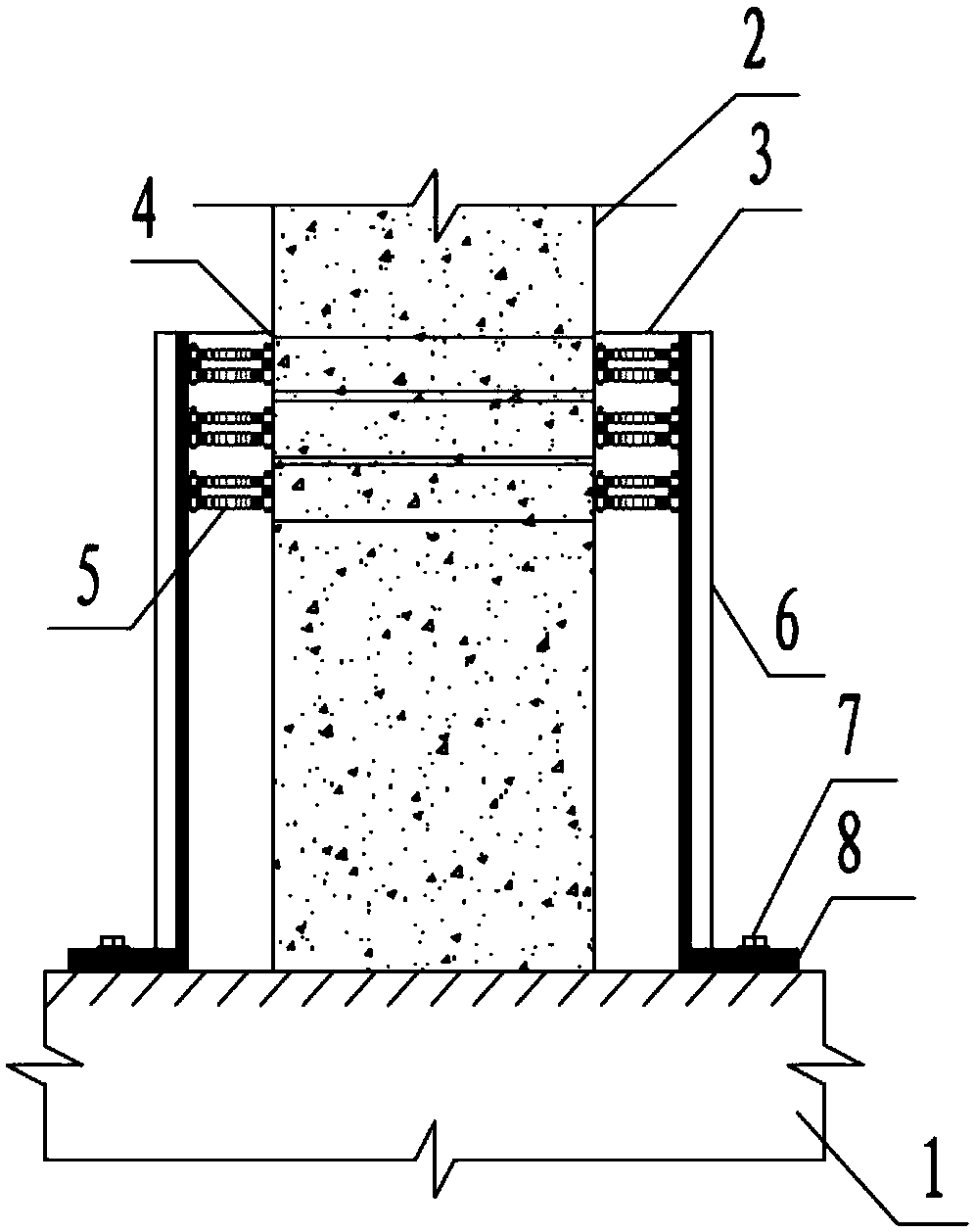

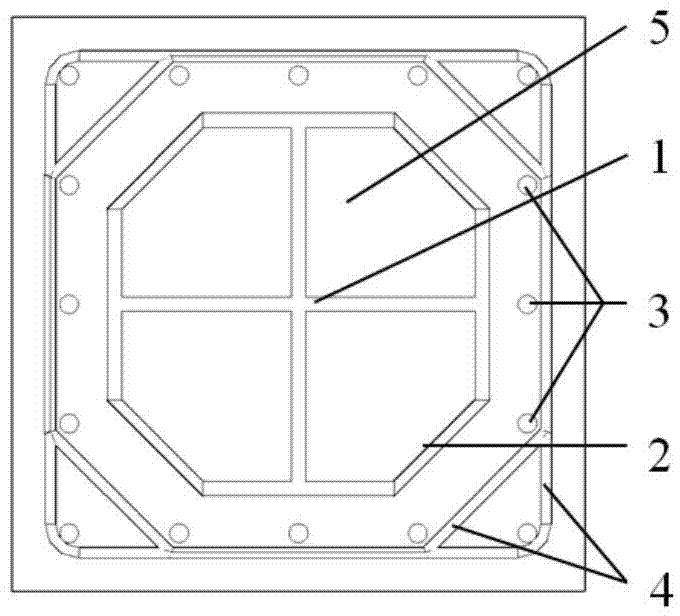

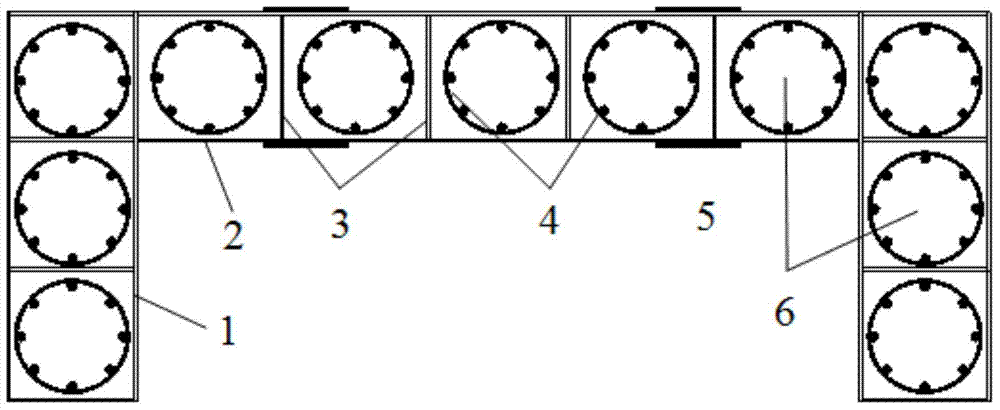

H-shaped steel bone-confined concrete column with round steel draw bars and fabrication method of column

InactiveCN103924740AReduce own overhangConstrained buckling deformationStrutsPillarsUltimate tensile strengthElastic plastic deformation

The invention relates to a steel bone concrete column, and particularly relates to an H-shaped steel bone-confined concrete column with round steel draw bars. The H-shaped steel bone-confined concrete column with the round steel draw bars comprises an H-shaped steel bone, the round steel draw bars, longitudinal reinforcement, a composite stirrup and concrete, wherein the round steel draw bars are connected with two flanges, at the outer sides of the flanges and near the free edges, of the H-shaped steel bone through bolts, so that the free extension length of each flange is effectively reduced, buckling deformation of the flanges is constrained, and meanwhile, the inspection capability of internal concrete of the steel bone is enhanced by existence of the round steel draw bars. The round steel draw bars are arranged at intervals, and the internal part of the steel bone is communicated with external concrete in series, so that the pouring quality of the concrete is ensured. Therefore, the concrete disclosed by the invention has the relatively high strength and the good elastic-plastic deformation capacity, and the formed steel bone concrete column has the relatively high bearing capacity, ductility and energy-dissipating capacity.

Owner:BEIJING UNIV OF TECH

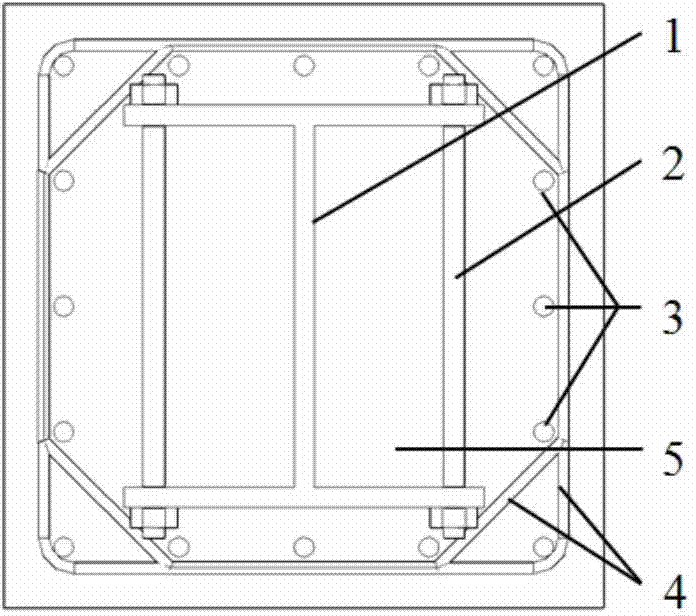

Box-type steel bone-confined concrete column with round steel draw bars and fabrication method of column

InactiveCN103924739AEffective knotReduce calculation lengthStrutsPillarsUltimate tensile strengthElastic plastic deformation

The invention relates to a steel bone concrete column, and particularly relates to a box-type steel bone-confined concrete column with round steel draw bars. The box-type steel bone-confined concrete column with the round steel draw bars comprises a box-type steel bone, the round steel draw bars, longitudinal reinforcement, a composite stirrup and concrete, wherein the round steel draw bars are connected with steel plates at two opposite edges of the box-type steel bone through bolts in the middles of the steel plates in a sectioning manner, so that the calculated length of each edge steel plate of the box-type steel bone is effectively reduced, the buckling deformation of each edge steel plate is constrained, and meanwhile, the inspection capability of internal concrete of the steel bone is enhanced by existence of the round steel draw bars. The round steel draw bars are arranged at intervals, so that the pouring quality of the concrete is ensured when the edge steel plates of the box-type steel bone are constrained. Therefore, the concrete disclosed by the invention has the relatively high strength and the good elastic-plastic deformation capacity, and the formed steel bone concrete column has the relatively high bearing capacity, ductility and energy-dissipating capacity.

Owner:BEIJING UNIV OF TECH

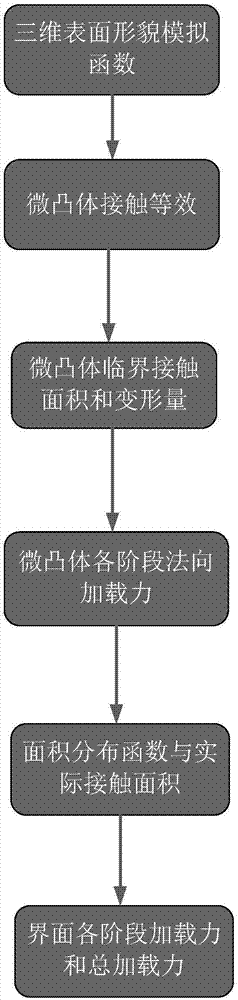

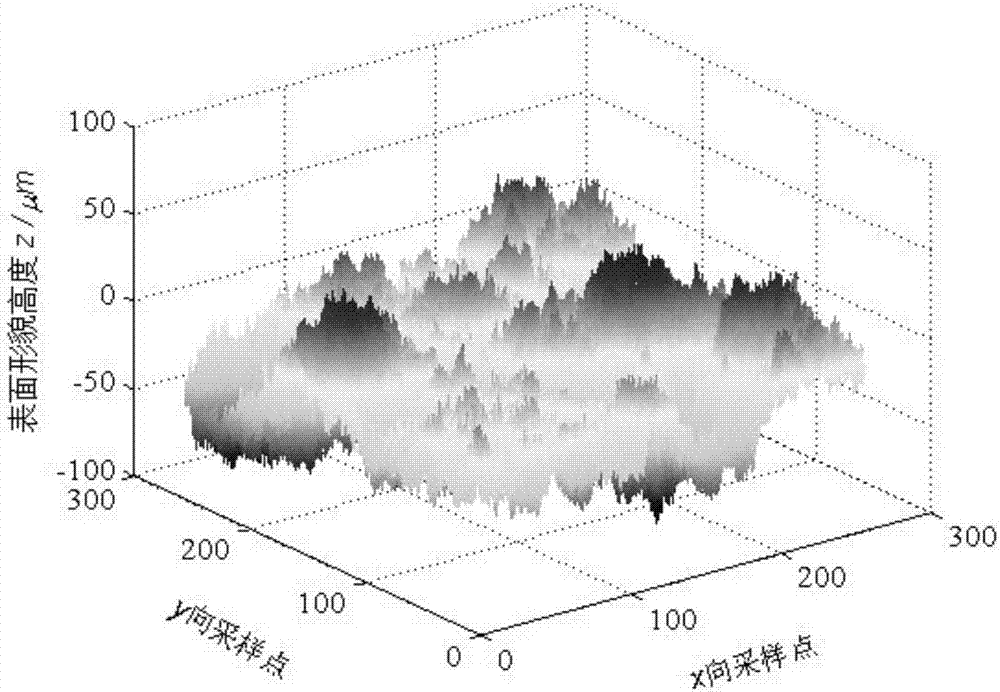

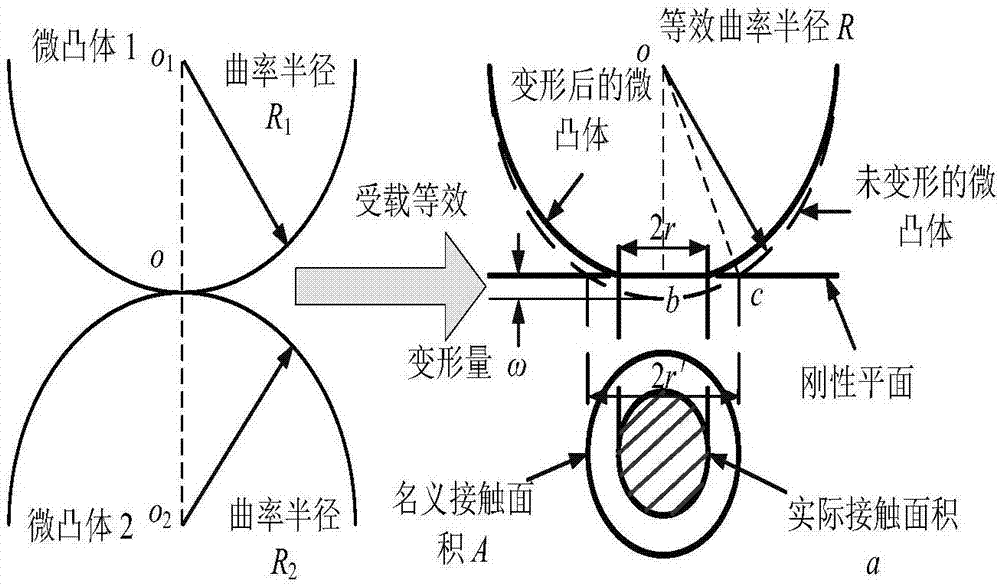

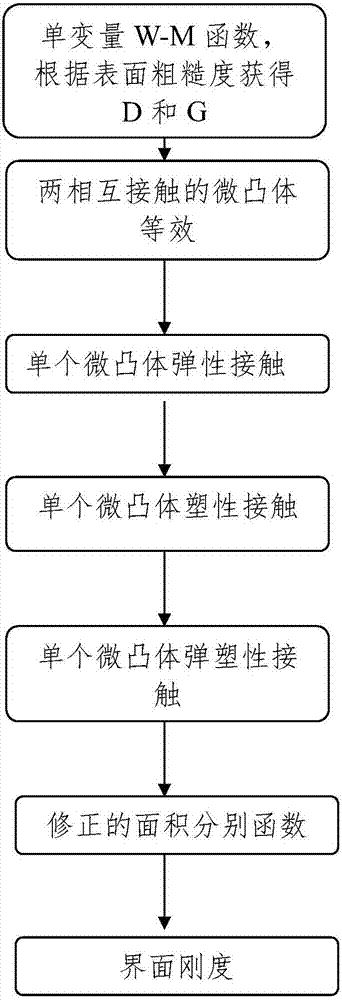

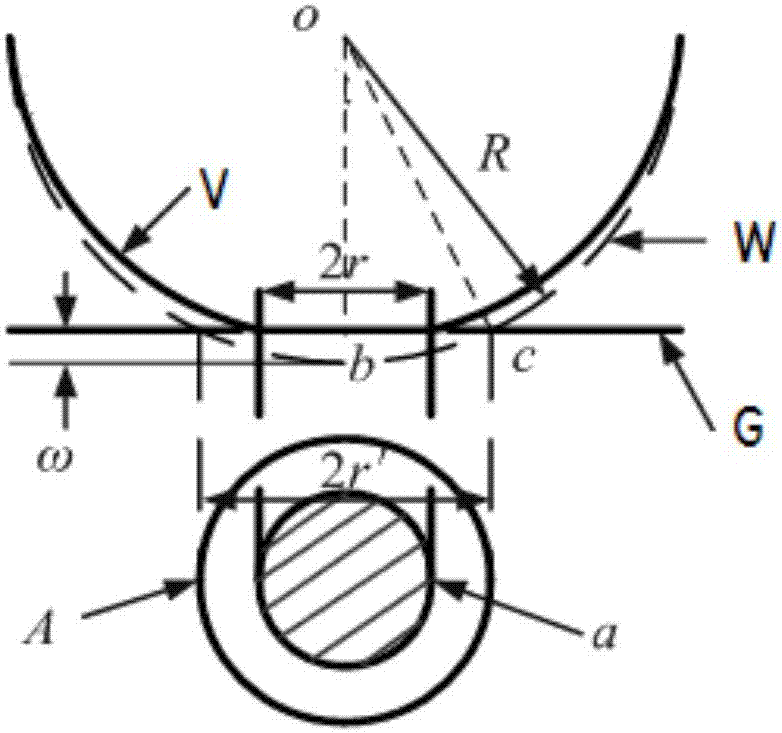

Prediction method of interface loading force in consideration of three-dimensional fractal

The invention discloses a prediction method of interface loading force in consideration of three-dimensional fractal. When two metal surfaces are contacted with each other, the formed interface contact is the contact among micro-bulges in fact from micro perspective. The loaded micro-bulges experience three stages of deformations of elasticity, elasticity-plasticity and plasticity in succession. In consideration of the three-dimensional fractal distribution characteristic of the micro-bulges in the interface, a prediction method of metal interface loading force under dry friction is provided based on fractal geometry theory and Hertz contact theory. The method considers three-dimensional fractal surface topography, friction coefficient and elastic-plastic deformation on the contact interface on the basis of the conventional contact analysis. The method makes the interface loading force which is hard to detect easy to obtain with simple calculation and easy operation, capable of being applied to interfacial dynamic characteristics analysis of precision machinery in projects.

Owner:NORTHEASTERN UNIV

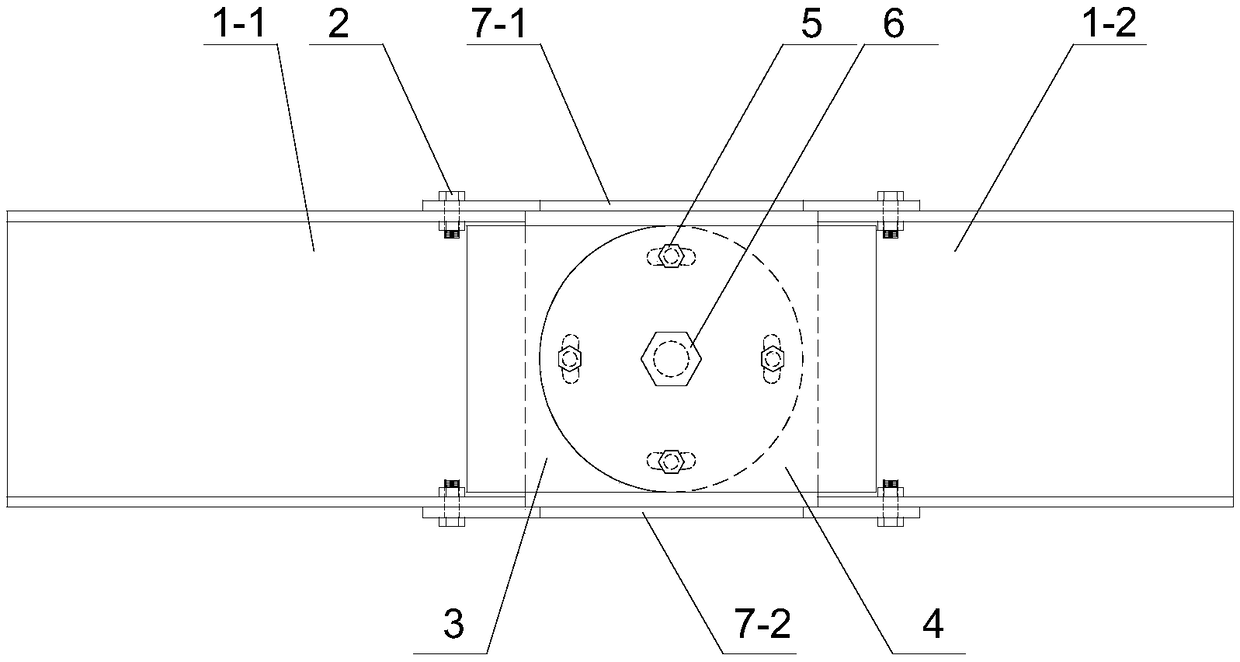

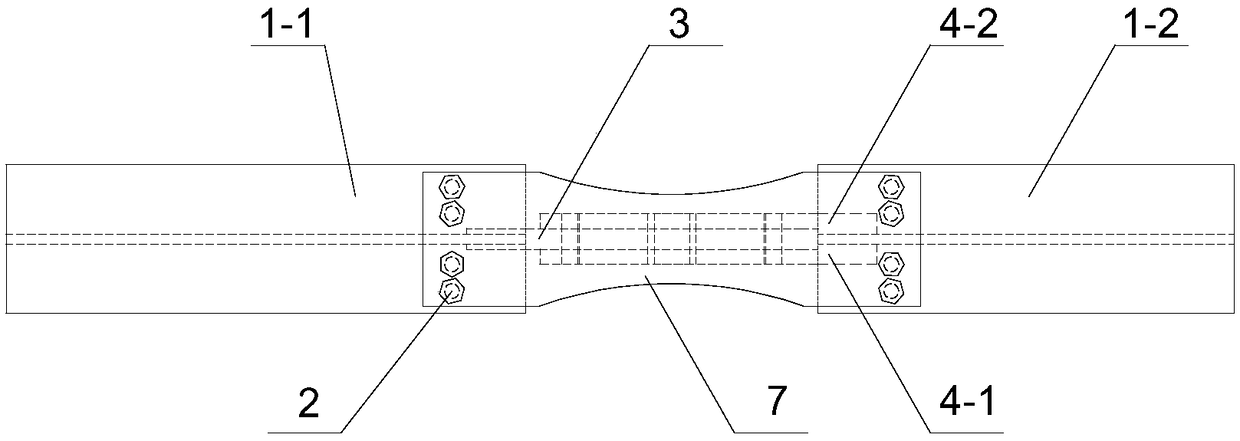

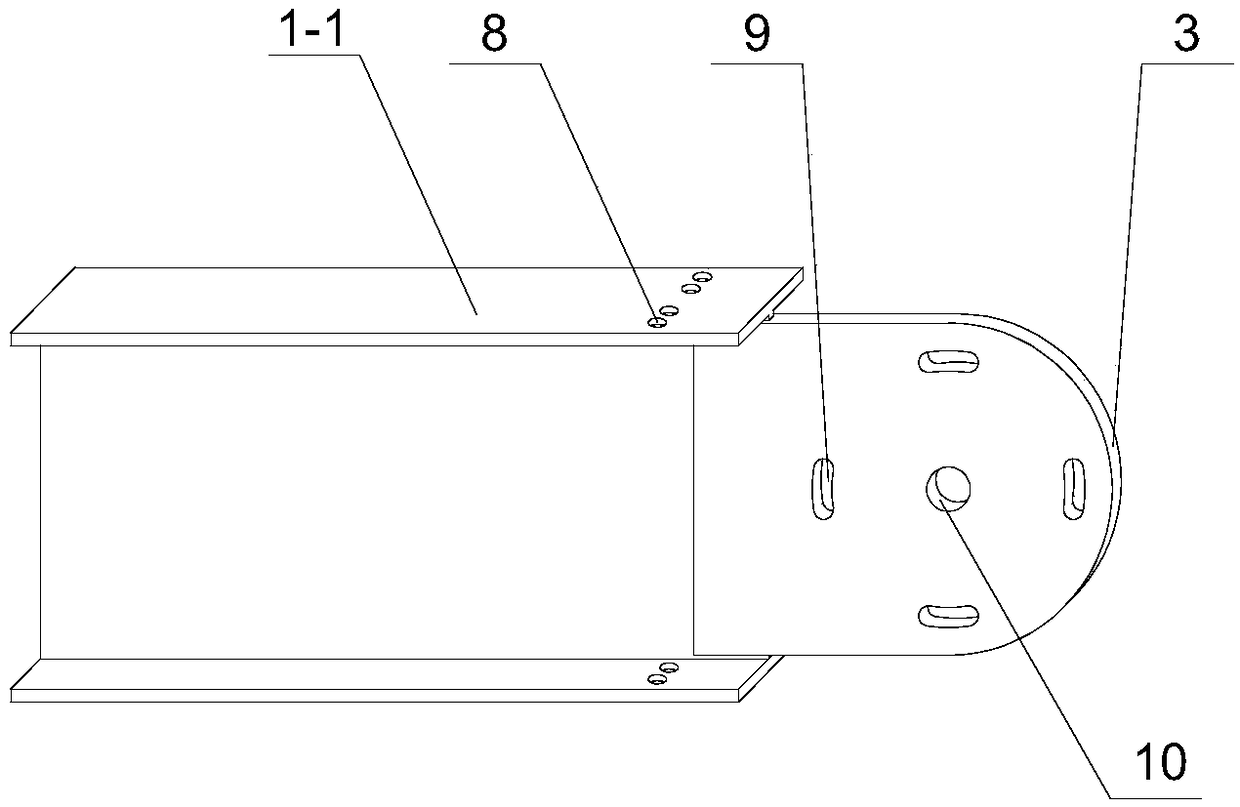

Self-damage energy-consuming repairable plastic hinge

InactiveCN108867865AImprove deformation abilityReduce energy consumptionProtective buildings/sheltersShock proofingArchitectural engineeringFixed energy

Provided is a self-damage energy-consuming repairable plastic hinge. The self-damage energy-consuming repairable plastic hinge comprises a fixing unit, a rotating unit and a connecting energy dissipation unit. A right beam end of a profile steel beam of the fixing unit is welded with a column of a structure, and double connecting plates are welded with the two sides of a left beam end of the profile steel beam respectively; a right beam end of a profile steel beam of the rotating unit is welded with a rabbet of a single connecting plate; a single connecting plate and double connecting plates of the connecting energy dissipation unit are in bolt connection through bolt holes, and the two ends of each fixing energy dissipation steel sheet are connected with the profile steel beam and upper and lower flanges of the profile steel beam respectively through bolts. The single connecting plate is located between the double connecting plates and is in loading connection with the double connecting plates through bolts. The fixing energy dissipation steel sheets are connected to upper and lower flange plates of the profile steel beam respectively through high-strength bolts, and the shape ofeach fixing energy dissipation steel sheet is 'dog-bone'-shaped to ensure that the process of the elastic plastic deformation to damage occurs in the middle part. The self-damage energy-consuming repairable plastic hinge only needs to replace the fixing energy dissipation steel sheets and resets after an earthquake, and the self-damage energy-consuming and post-earthquake rapid repair of partial components can be achieved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

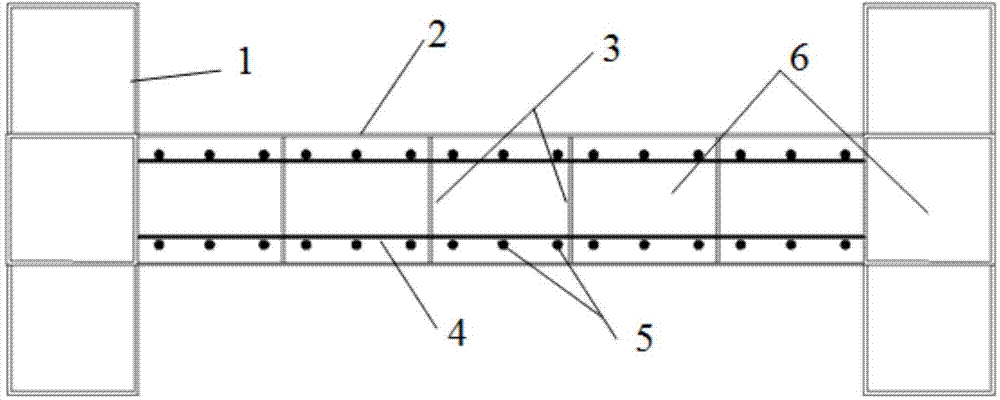

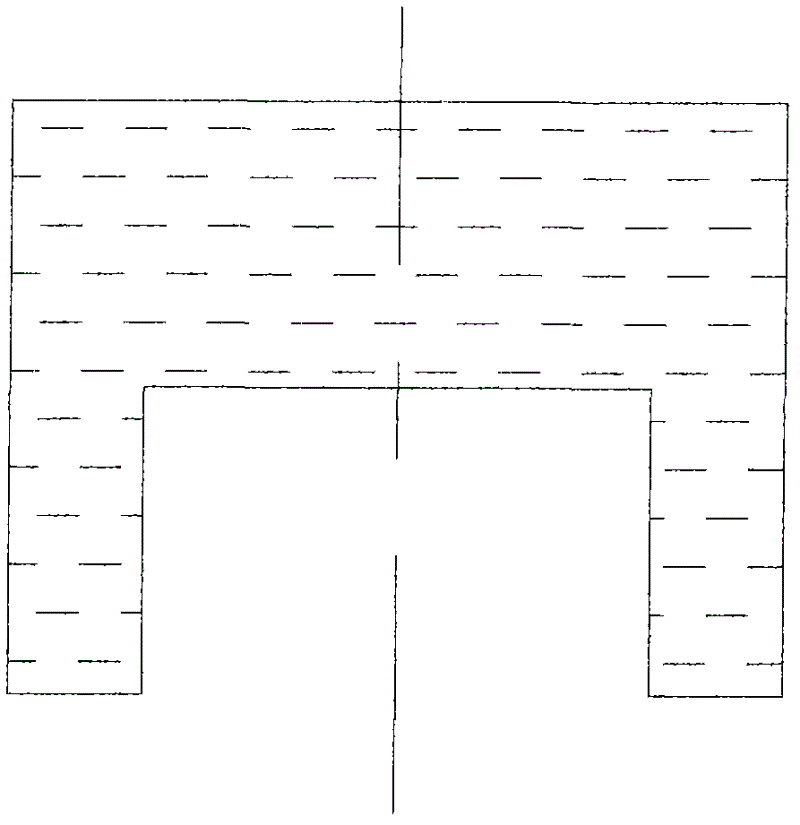

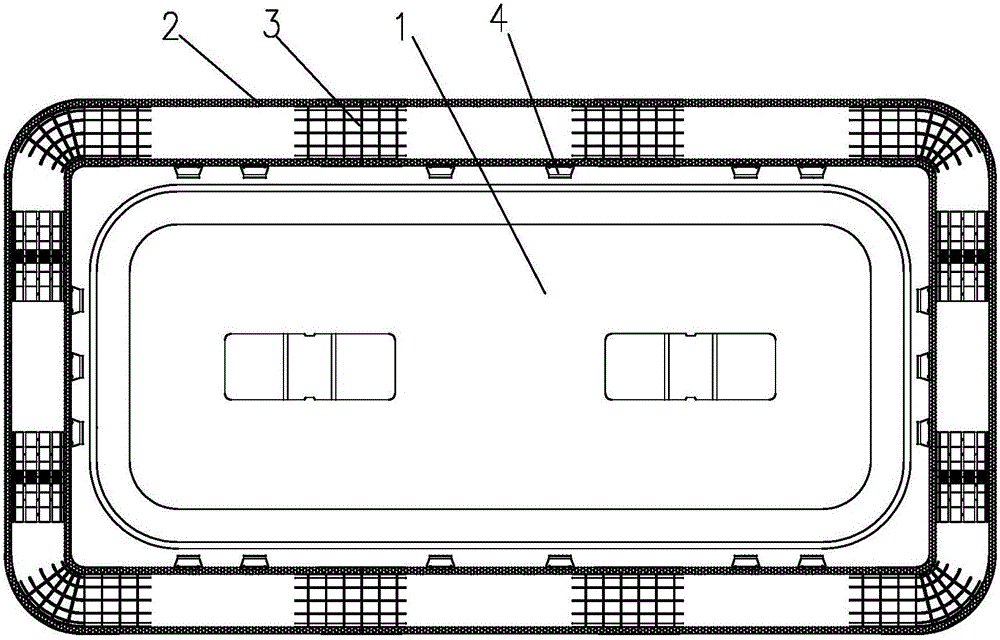

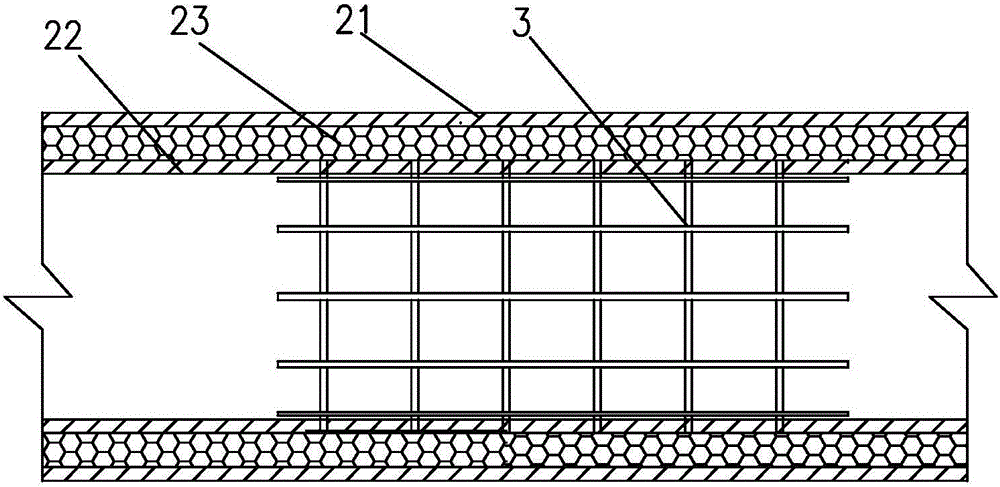

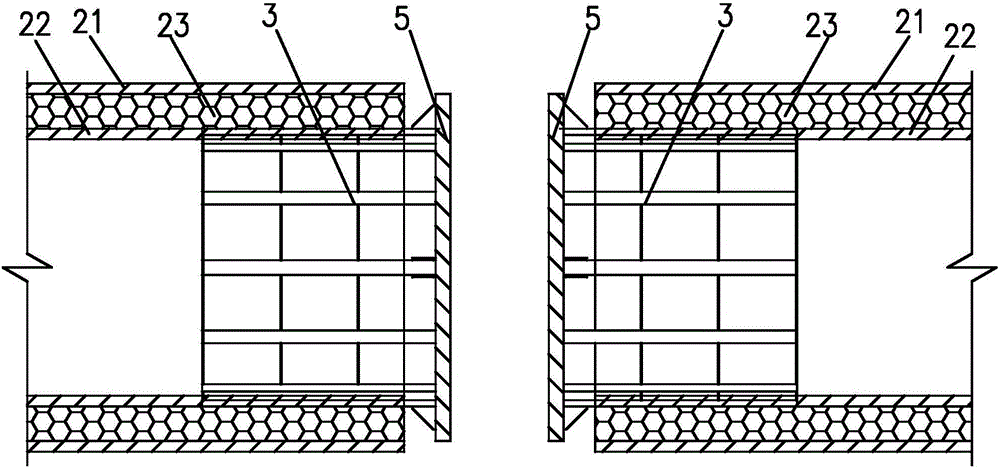

I-shaped multi-cavity double-steel-plate shear wall with built-in steel mesh reinforcement and manufacturing method

InactiveCN103883031AConstrained buckling deformationImprove the stable bearing capacityWallsBuilding material handlingSheet steelMesh reinforcement

The invention relates to a double-steel-plate combined shear wall, in particular to an I-shaped multi-cavity double-steel-plate shear wall with built-in steel mesh reinforcement and a manufacturing method. According to the I-shaped multi-cavity double-steel-plate shear wall with the built-in steel mesh reinforcement, the I-shaped section is applicable to the arrangement mode of a shear wall body in a building structure, the space between the inner sides of two steel plates is filled with concrete, buckling deformation of the steel plates can be effectively restrained, and the buckling strength of the steel plates is improved; due to the fact that the internal concrete is restrained by the steel plates on the two sides, cavity separating plates and steel reinforcement meshes in a double mode, the elastic-plastic deformation capacity and ultimate compressive strength of the concrete are improved; the flange portion of the shear wall body with the I-shaped section has a good restraint effect on a web wall, the bearing capacity, in the plane, of the combined shear wall and the bearing capacity, outside the plane, of the combined shear wall are remarkably improved, and thus the combined shear wall can have the high bearing capacity and the high elastic-plastic deformation capacity.

Owner:BEIJING UNIV OF TECH

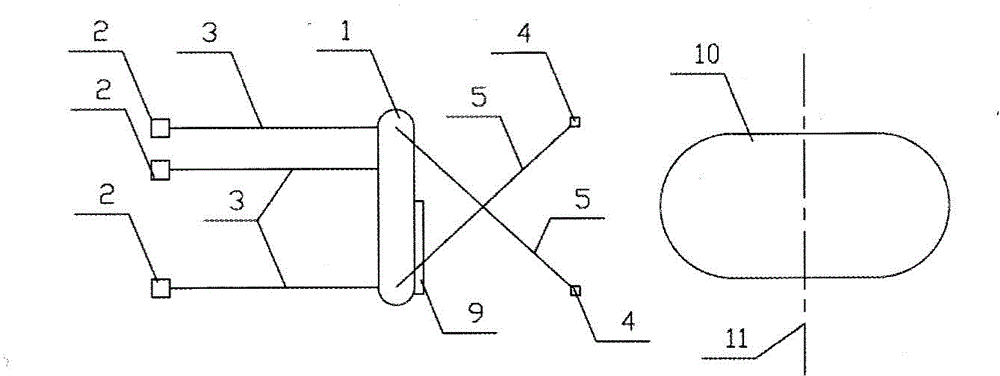

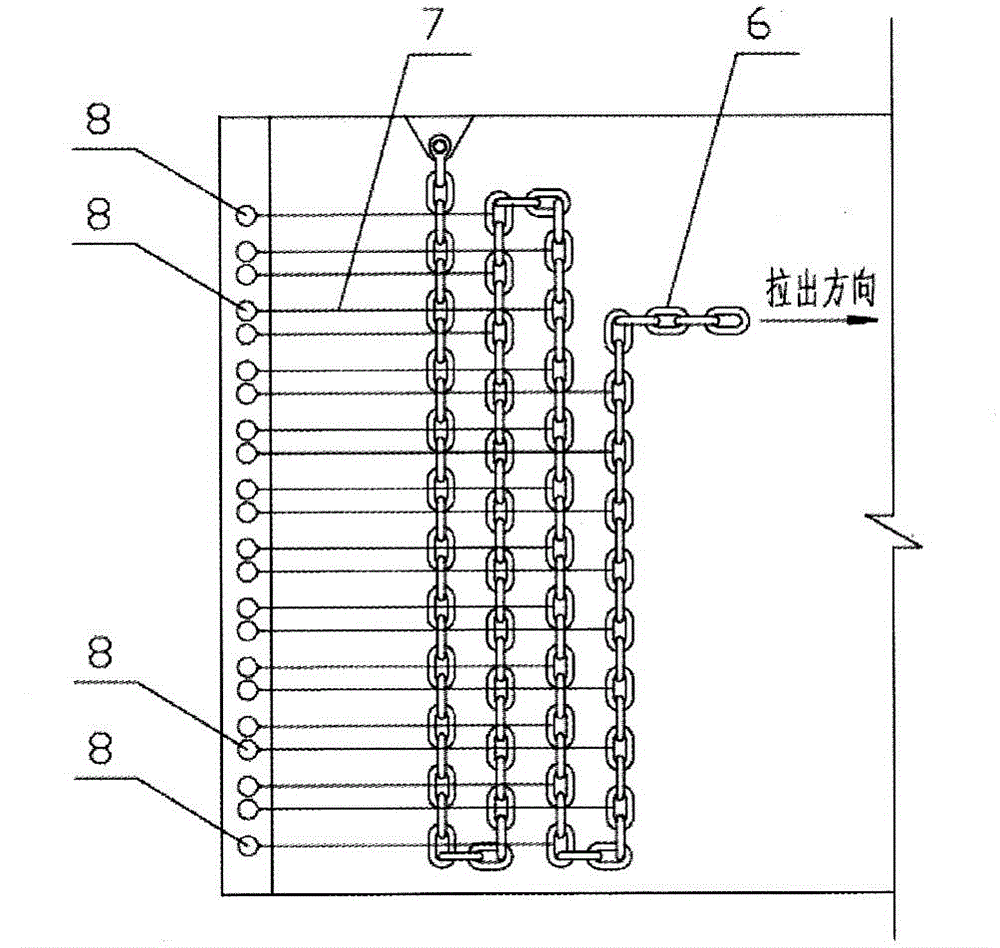

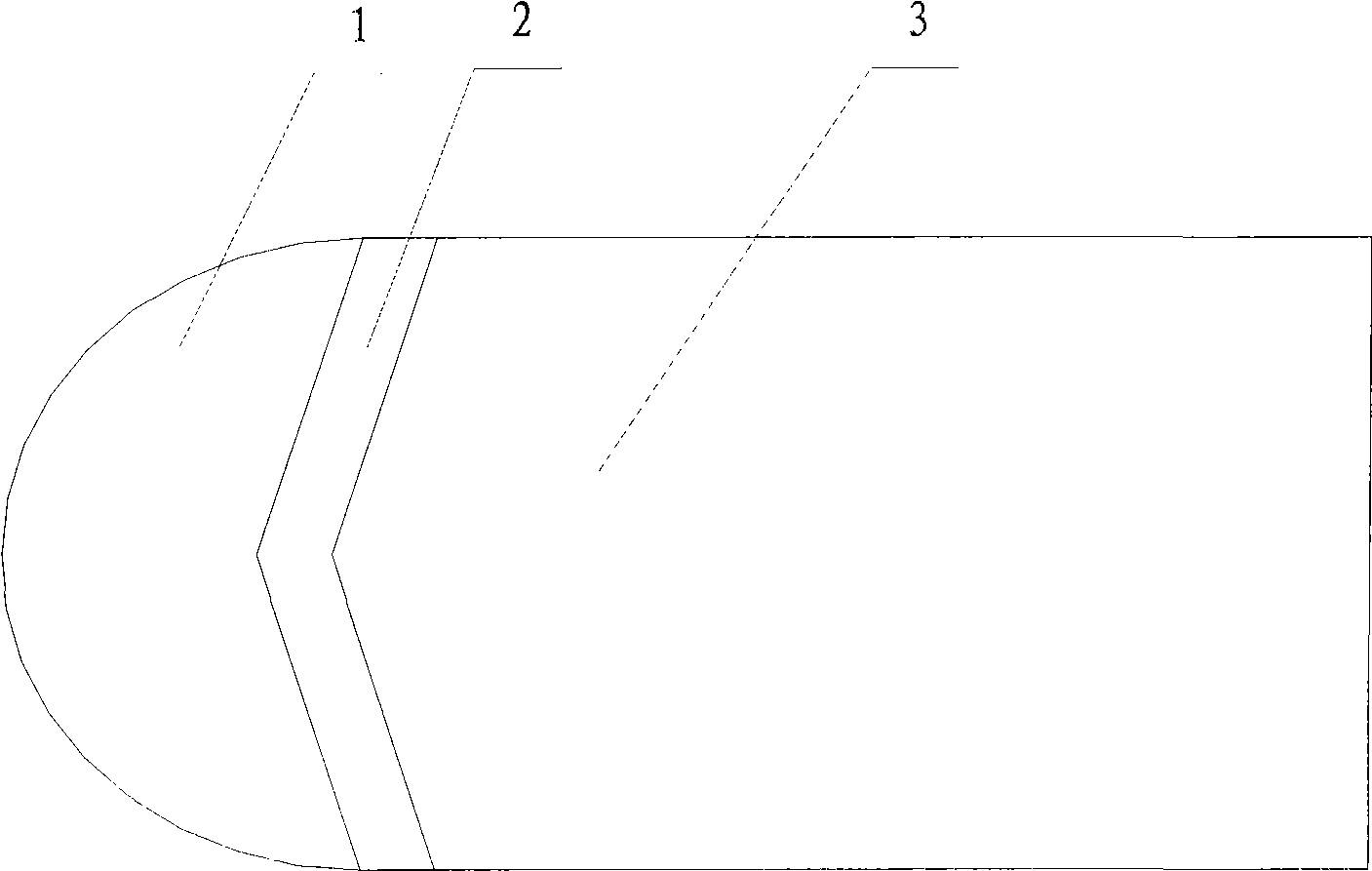

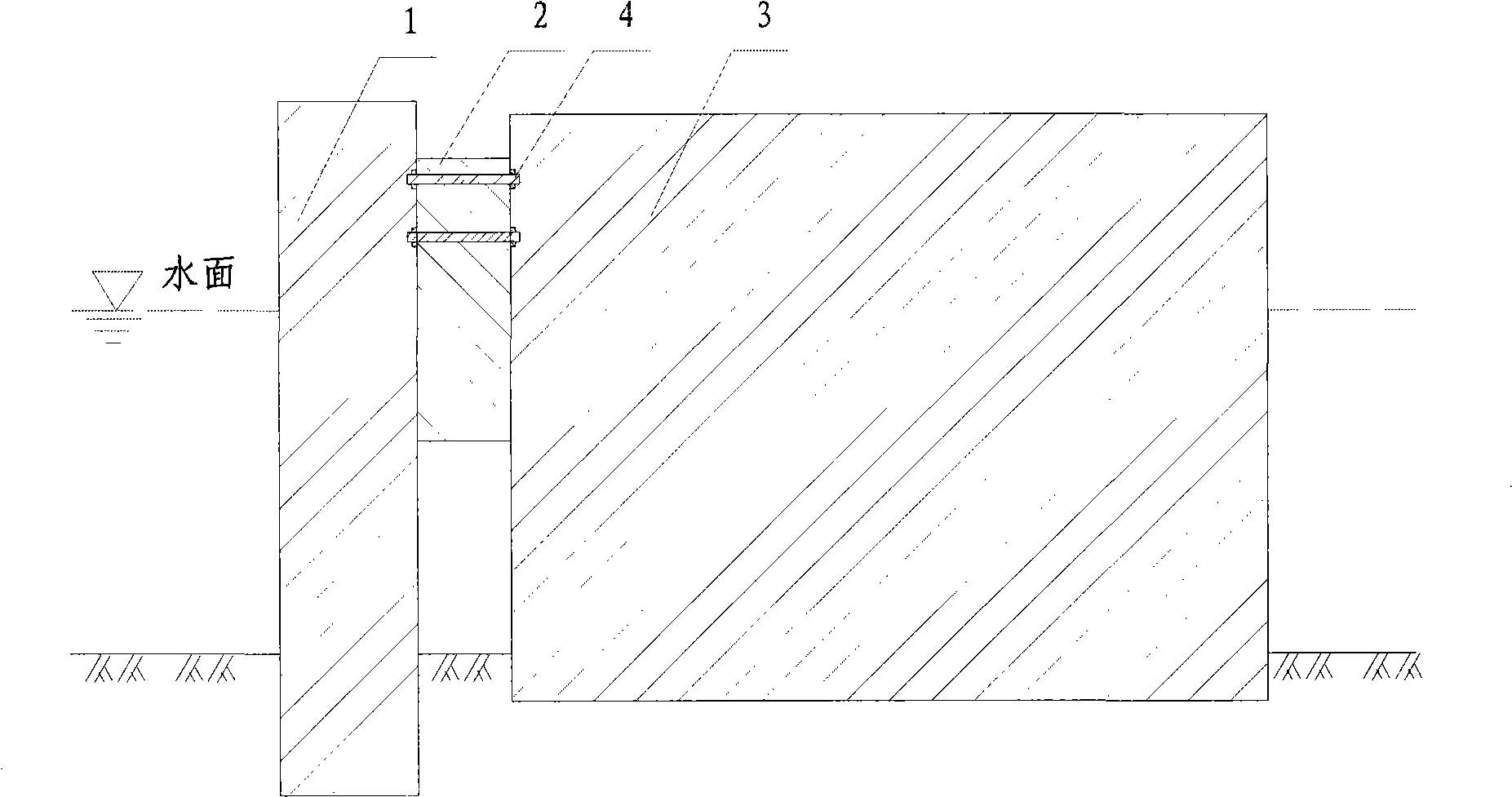

Mooring buffering ship collision preventive system

ActiveCN104314051AReduce the interaction forceReduce impact forceClimate change adaptationShipping equipmentMarine engineeringElastic plastic deformation

A mooring buffering ship collision preventive system comprises a floater, main anchors, main ropes, damping units, a buffering pad, auxiliary anchors, auxiliary ropes and the like. The floater is moored through the main anchors, the main ropes, the auxiliary anchors and the auxiliary ropes; at least two damping units on the floater are disposed at intervals; each damping unit is composed of a damping chain, an energy-dissipating rope and the like. The mooring buffering ship collision preventive system has the advantages that energy can be dissipated by continuously elongating and breaking the energy-dissipating ropes, the moving direction of a ship can be changed through the floater which is in oblique connection with the axis of a bridge, energy can also be dissipated by elastic plastic deformation of a collision preventive pad arranged on the floater and of a floater structure, mutual action between the ship and collision preventive equipment can be greatly reduced, impact that a pier possibly bears is greatly reduced, and the safety of the pier and of the ship can be protected.

Owner:NANJING GUANGBO ENG TECH

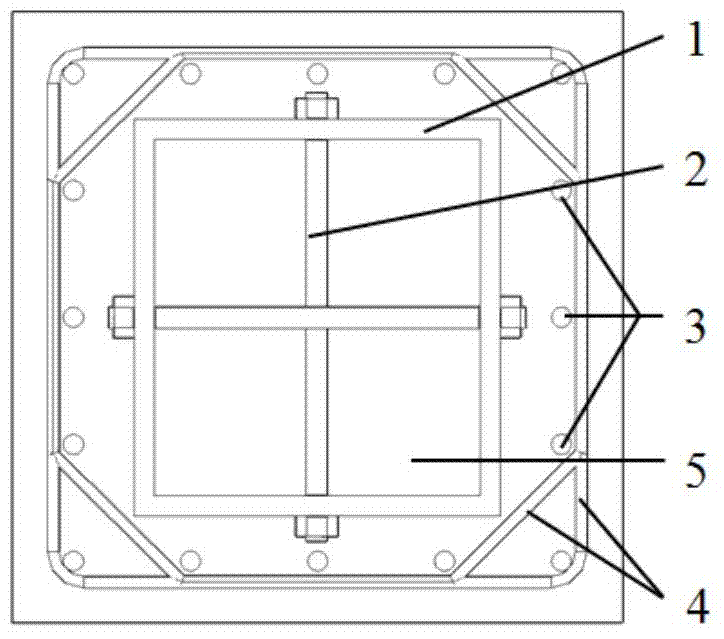

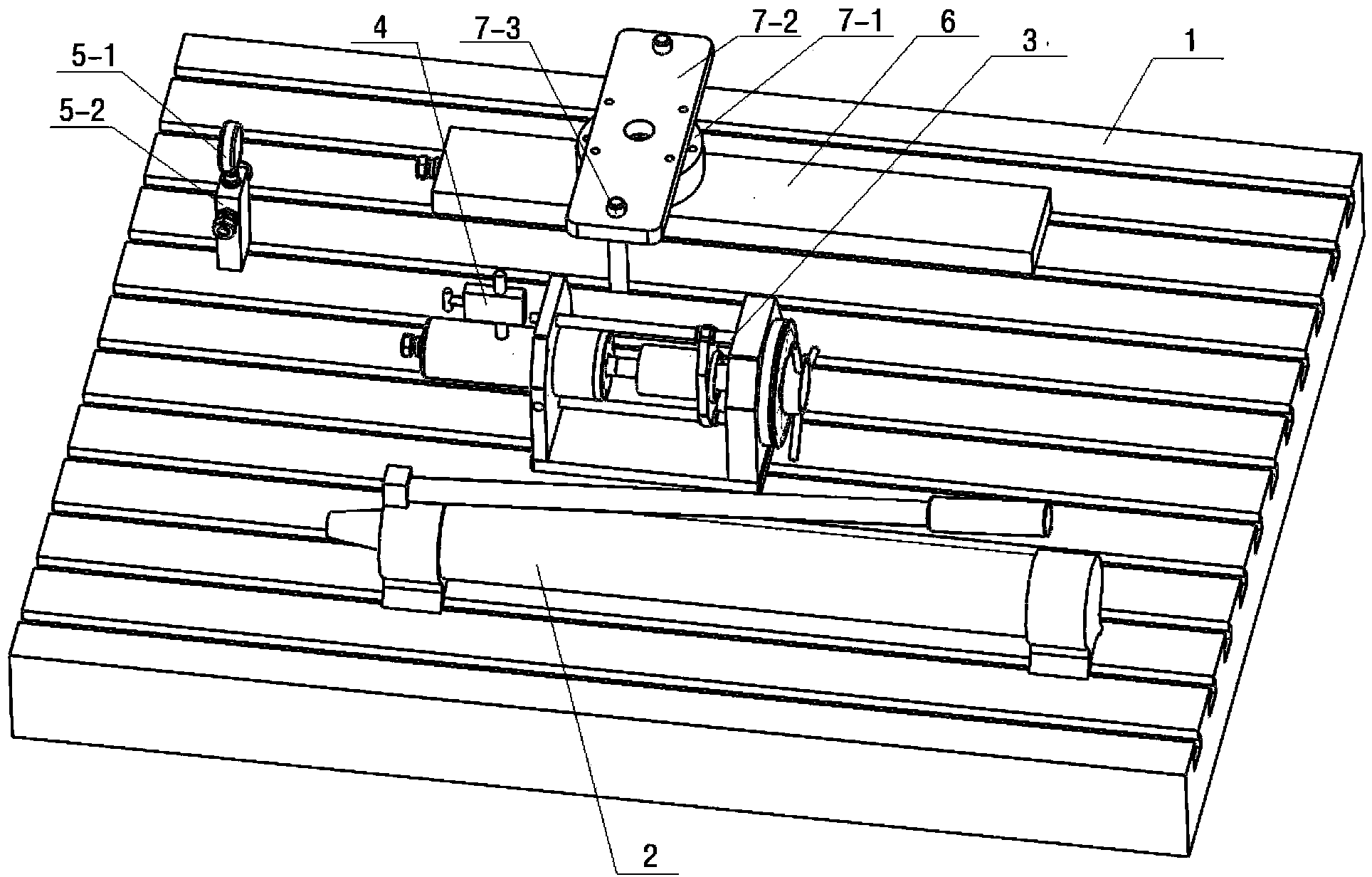

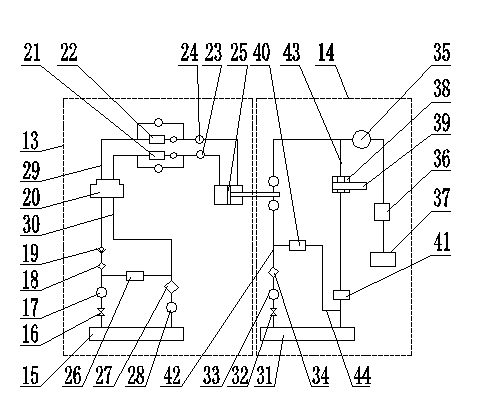

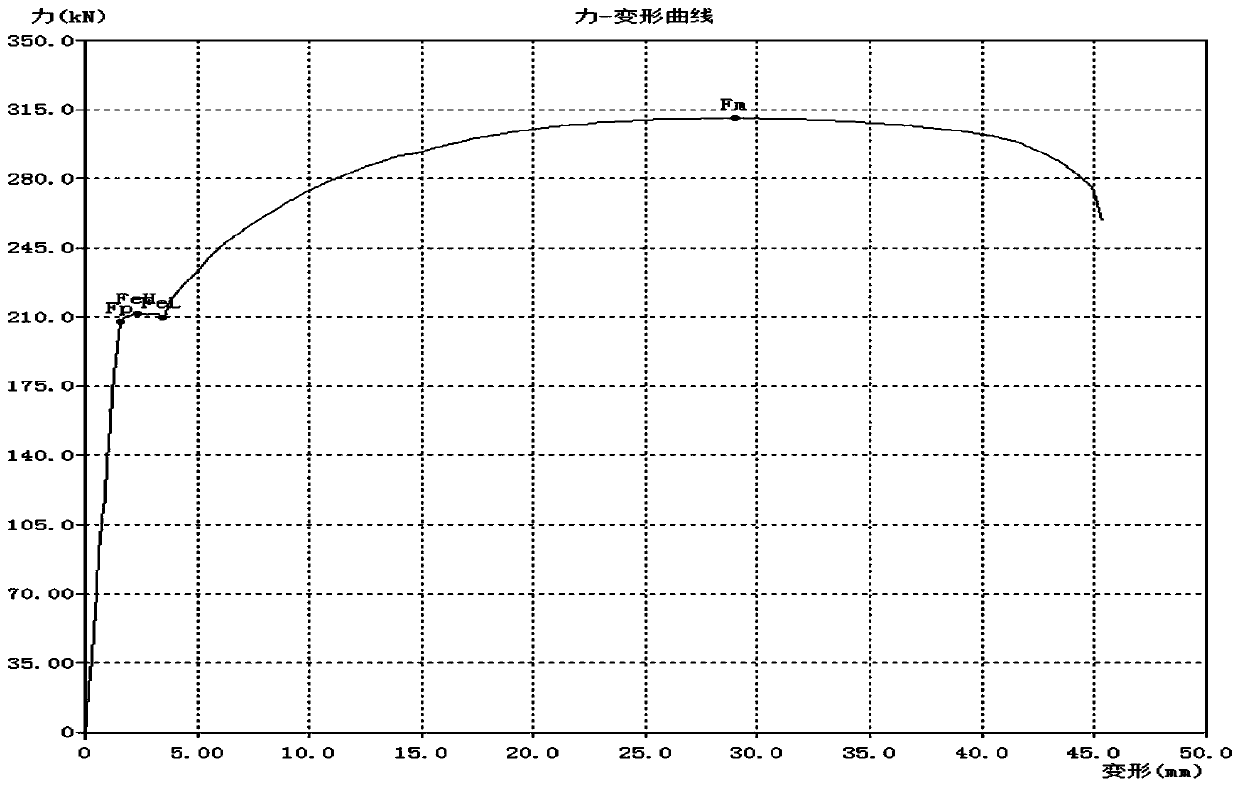

Thin-wall pressurization structure elastic-plastic deformation experimental study device

InactiveCN103353430AGuaranteed accuracyGuaranteed to be scientificMaterial strength using repeated/pulsating forcesEngineeringContact type

The invention relates to a thin-wall pressurization structure elastic-plastic deformation experimental study device, which is composed of an oil injection module, a pressure gauge, an experimental test piece, a micro-deformation test instrument and a pressure loading system. The oil injection module, the experimental test piece, and the micro-deformation test instrument are fixed on a test bench. The oil injection module includes a manual pump and a stop valve. The experimental test piece is provided with a thin-wall pressurization structure. The micro-deformation test instrument is a contact-type high precision displacement sensor. The pressure loading system comprises a loading plate, a load display system, and fastening trapezoidal screws. The experimental study device also includes a plunger precise pressure pump, which consists of a plunger pressurization structure, a mechanical drive structure and a frame. The experimental study device provided in the invention has the characteristics of high pressure regulating precision, convenient operation and low development cost, and can be used in experimental study processes of thin-wall pressurization structure sensitivity and compressive sensitivity.

Owner:郑祥模

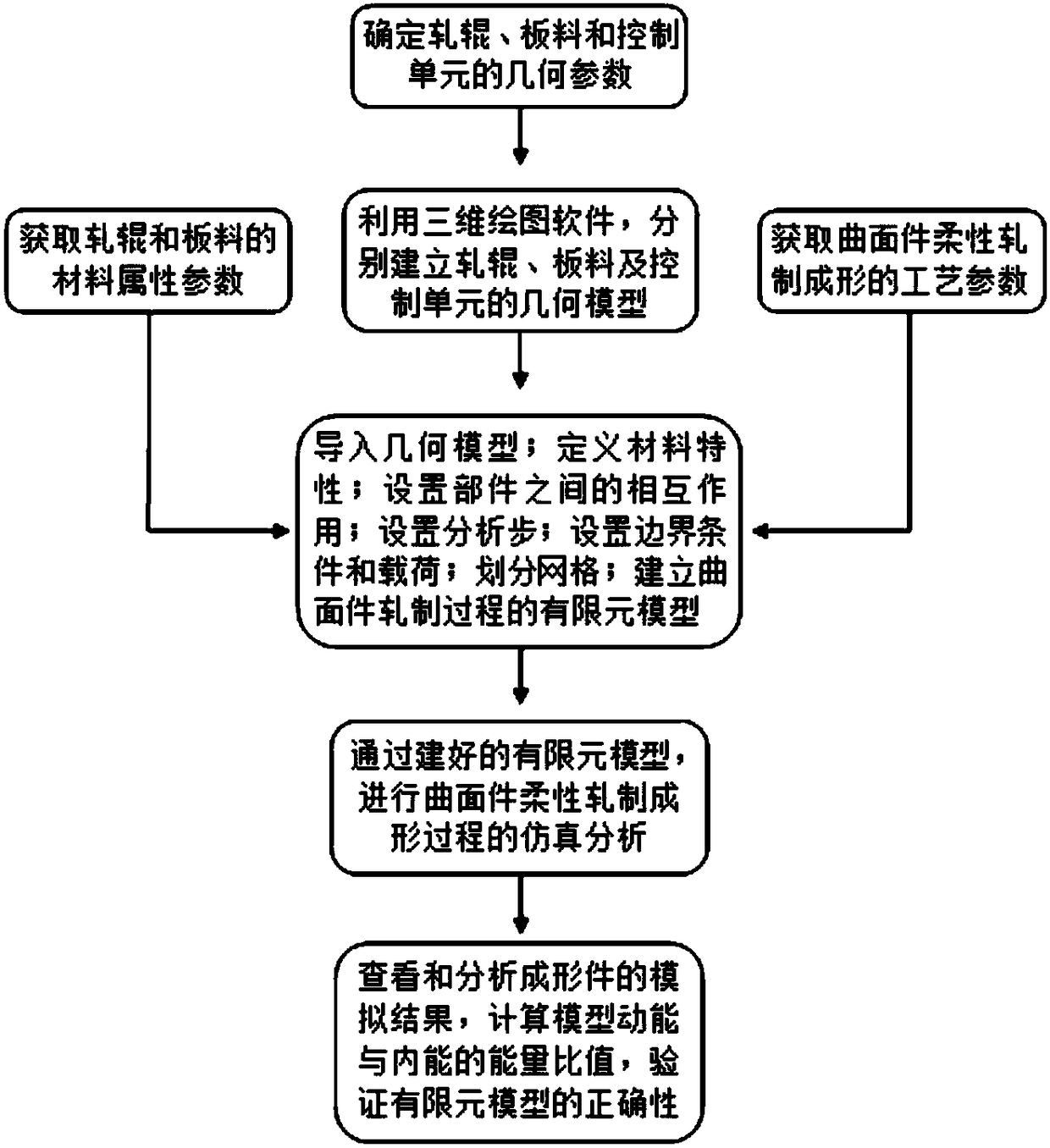

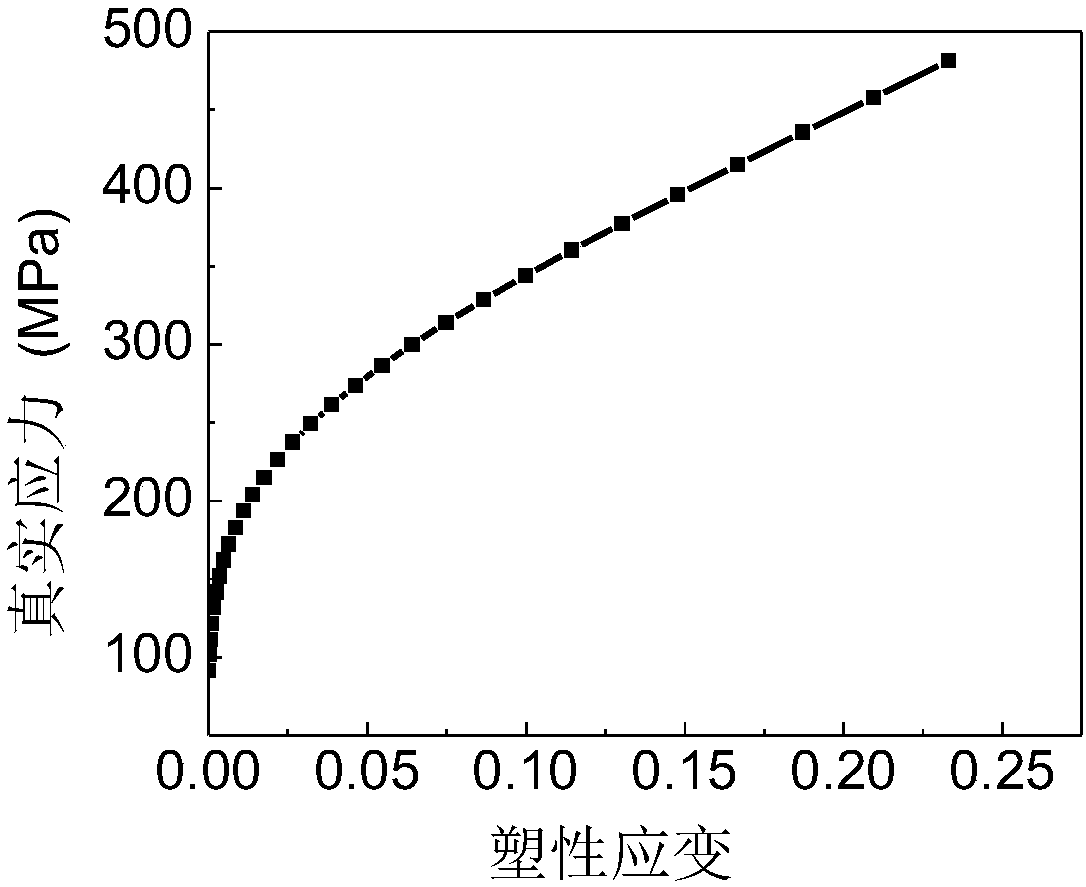

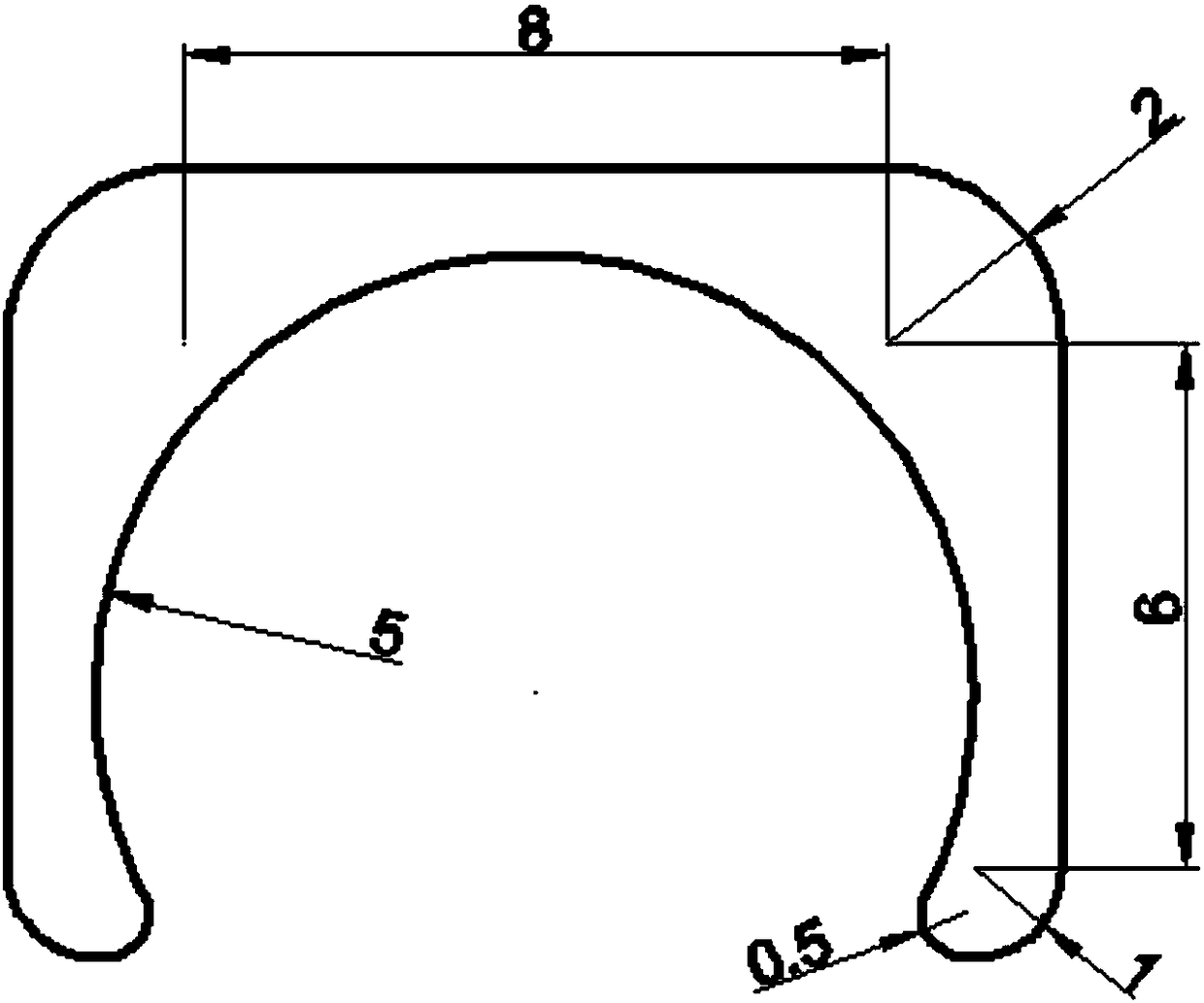

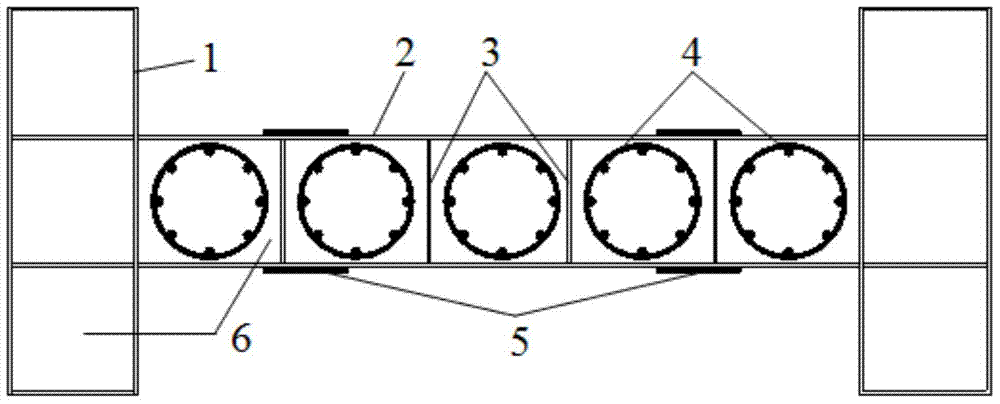

Numerical simulation method of flexible rolling and forming process of curved-surface part

InactiveCN108108582AGuaranteed accuracyGuaranteed reliabilityDesign optimisation/simulationSpecial data processing applicationsCouplingElement analysis

The invention discloses a numerical simulation method of a flexible rolling and forming process of a curved-surface part. The numerical simulation method comprises the following steps: acquiring material attribute parameters of a roller and a sheet material; determining geometric parameters of the roller, the sheet material and a control unit; establishing a geometric model of the roller, the sheet material and the control unit by utilizing a three-dimensional drawing software; acquiring technological parameters of flexible rolling and forming of the curved-surface part; establishing a finite-element analysis model; carrying out simulation analysis of the rolling and forming of the curved-surface part; identifying the accuracy of the finite-element analysis model. According to the method disclosed by the invention, the roller is set to be an elastic body, and elastic deformation of the roller and elastic-plastic deformation of the sheet material are coupled; the control unit is additionally arranged and is used for controlling a roller type of the roller; movement coupling constraint is arranged on the end face of the roller so that the roller rotates around the bent axis of the roller. The numerical simulation method disclosed by the invention reflects a real structure of a forming device and the rolling and forming process of the curved-surface part can be accurately simulated; the numerical simulation method has relatively high precision and efficiency, and evidences can be provided for designing and optimizing a flexible rolling and forming technology of the curved-surface part.

Owner:JILIN UNIV

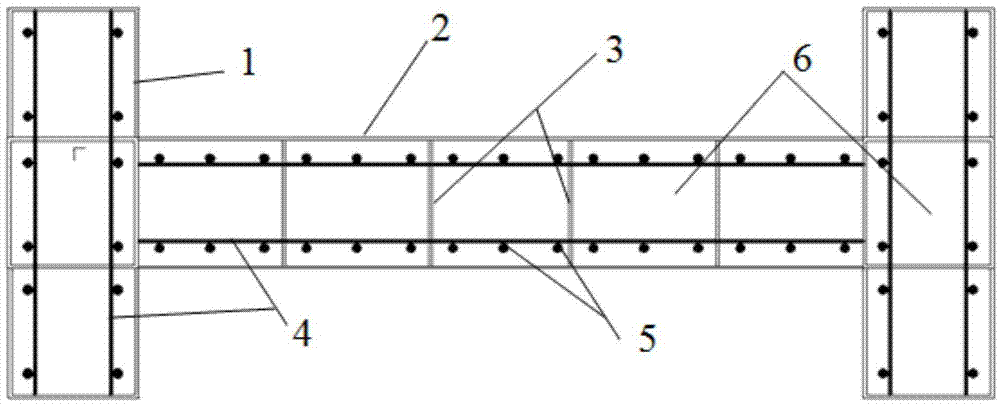

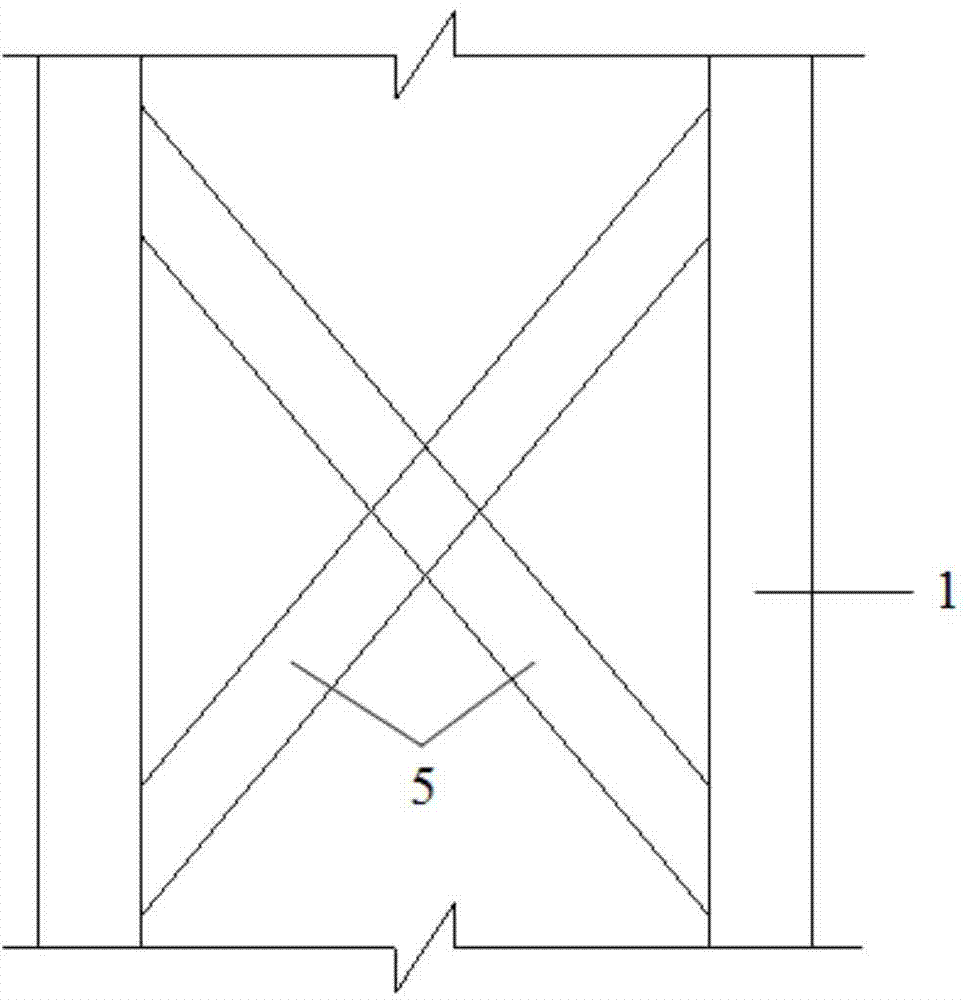

I-shaped steel plate shear wall with built-in round steel reinforcement cages and externally-attached steel plate supports and manufacturing method

InactiveCN103883032AConstrained buckling deformationImprove the stable bearing capacityWallsShock proofingSheet steelCompressive strength

The invention relates to a combined steel plate shear wall, in particular to an I-shaped steel plate shear wall with built-in round steel reinforcement cages and externally-attached steel plate supports and a manufacturing method. According to the I-shaped steel plate shear wall, the I-shaped section is applicable to the arrangement mode of a shear wall body in a building structure, the space between the inner sides of two steel plates is filled with concrete, buckling deformation of the steel plates can be effectively restrained, and the buckling strength of the steel plates is improved; due to the fact that the internal concrete is restrained by the steel plates on the two sides, cavity separating plates and the round steel reinforcement cages in a double mode, the elastic-plastic deformation capacity and ultimate compressive strength of the concrete are improved; the steel plate supports can fully play a role as diagonal members, and provide high lateral-resistant rigidity and the high bearing capacity for a shear wall body; the flange portion of the shear wall body with the I-shaped section has a good restraint effect on a web wall, the bearing capacity, in the plane, of the combined shear wall and the bearing capacity, outside the plane, of the combined shear wall are remarkably improved, and thus the combined steel plate shear wall can have the high bearing capacity and the high elastic-plastic deformation capacity.

Owner:BEIJING UNIV OF TECH

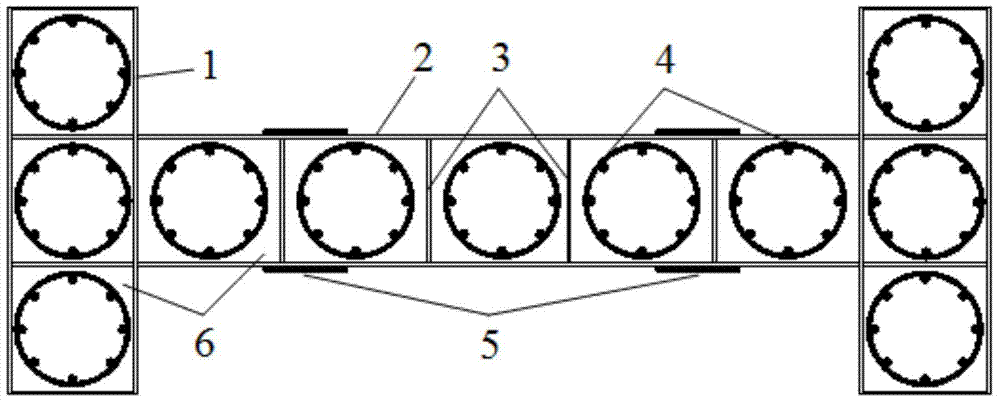

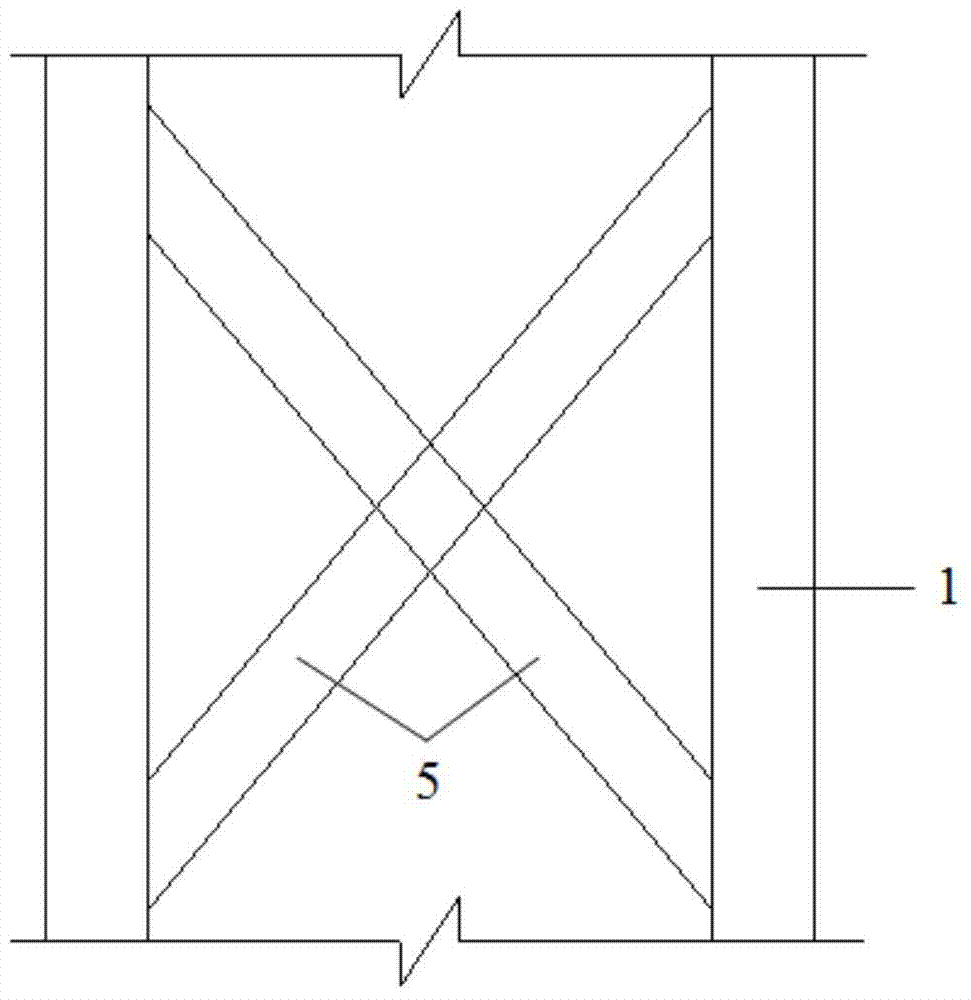

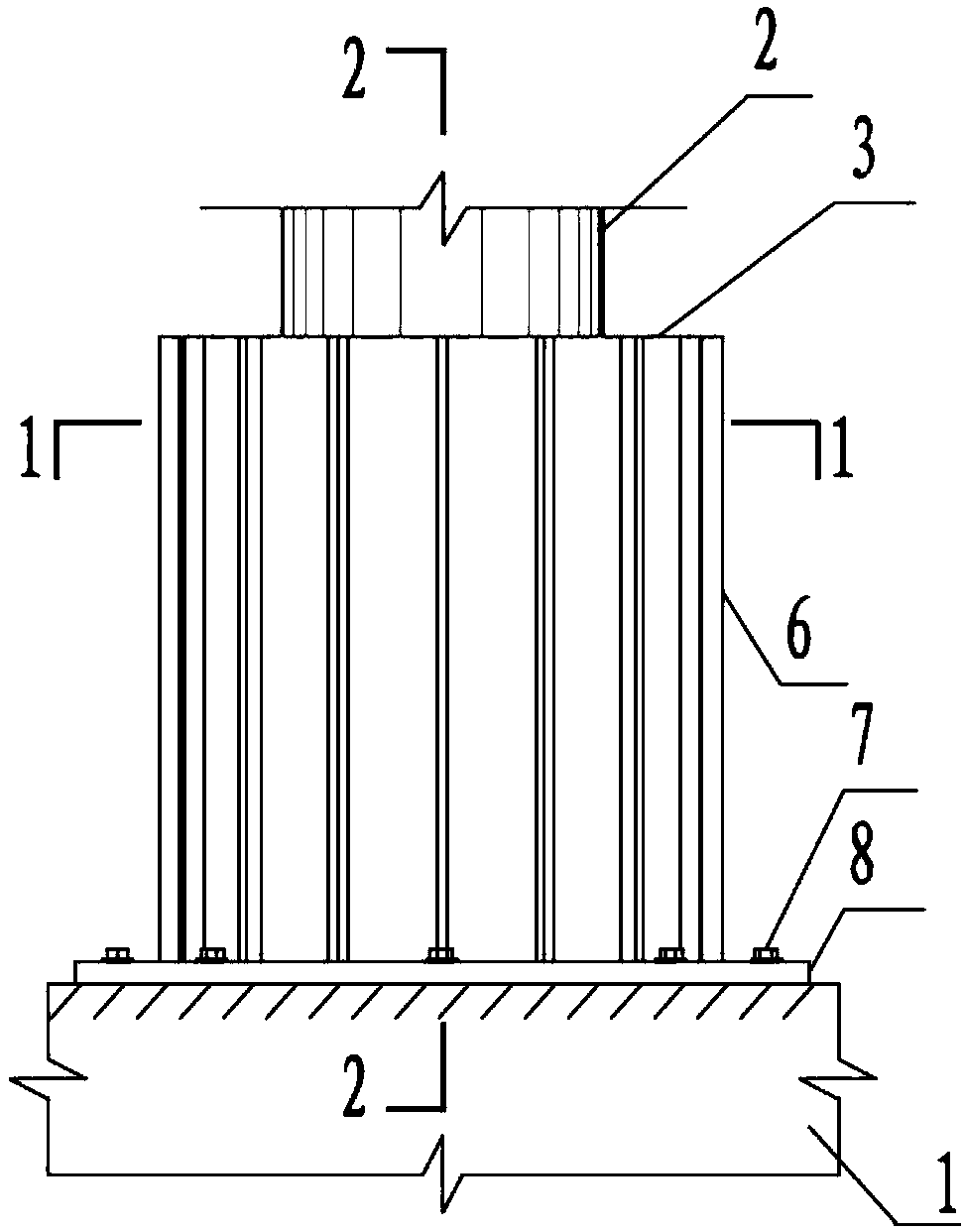

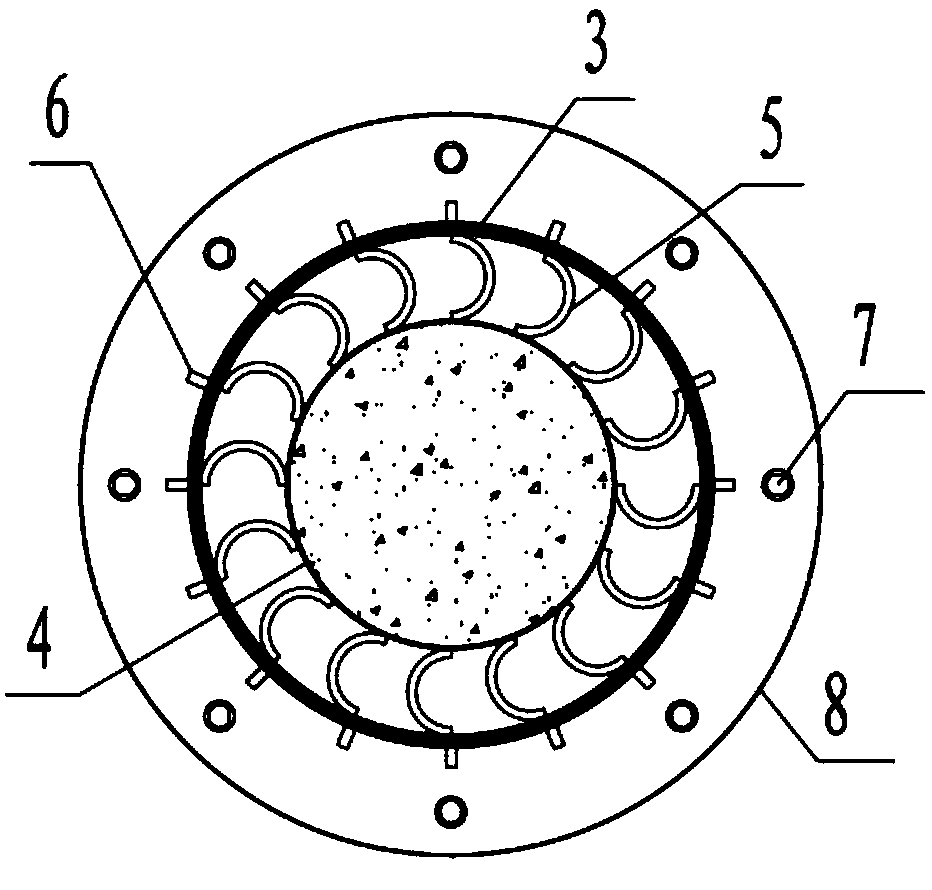

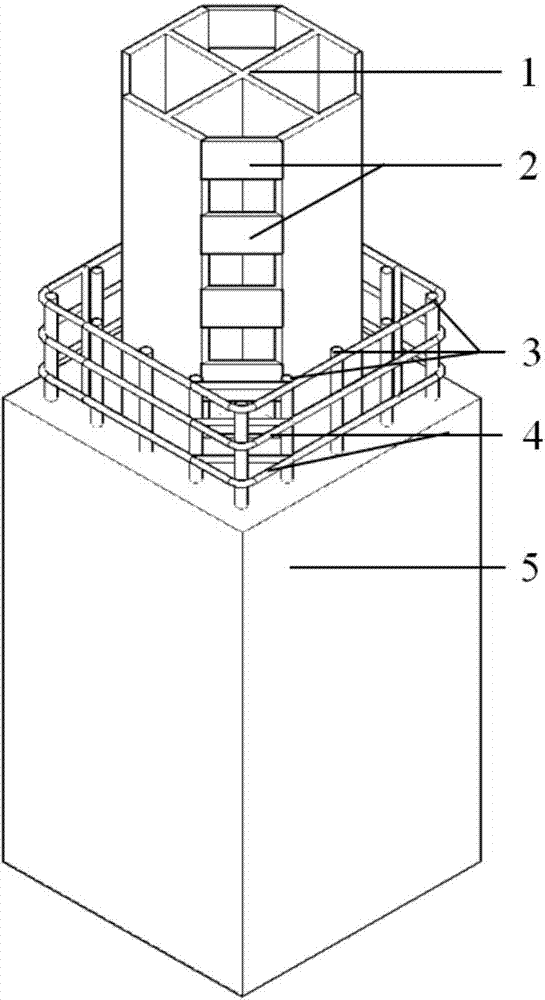

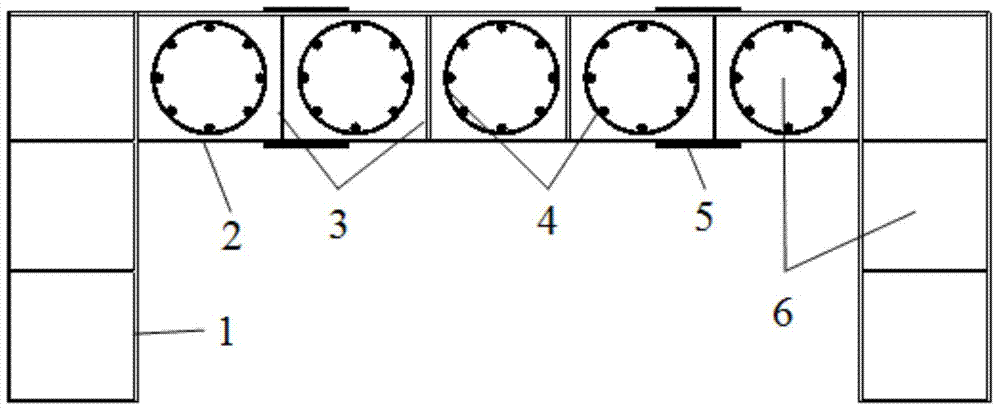

Multi-way shock absorbing device for bridge pier

PendingCN108691266ADoes not affect normal workReduce horizontal displacementBridge structural detailsBridge materialsElastic plasticElastic plastic deformation

The invention discloses a multi-way shock absorbing device for a bridge pier. The multi-way shock absorbing device for the bridge pier comprises an inner layer connecting plate and an outer layer fixing-supporting plate. The inner layer connecting plate and the outer layer fixing-supporting plate are detachably arranged on a pier column bearing platform and are arranged in the circumferential direction of the outer surface of a pier column. A plurality of elastic-plastic deformational components are uniformly distributed between the inner layer connecting layer and the outer layer fixing-supporting plate in the radial direction of the pier column section. Under the condition of usual using, the shock absorbing device keeps elastic, and normal operation of the bridge pier is not affected. Under the action of seismic loads, horizontal displacement of the bridge pier body occurs. When the bridge pier is overly displaced, the shock absorbing device yields, and an outer support device stillstays elastic. The shock absorbing device conducts reciprocation hysteretic energy dissipation through elastic-plastic deformation, so that the earthquake energy is dissipated, and the bridge pier horizontal displacement is reduced. The multi-way shock absorbing device of the column bridge pier is low in price, can be prefabricated in a factory, and can be assembled quickly in a construction sitewithout affecting normal using of the bridge. Moreover, the multi-way shock absorbing is convenient to replace after an earthquake, and can also be used as an anti-collision device of the pier bottom.

Owner:林同棪国际工程咨询(中国)有限公司

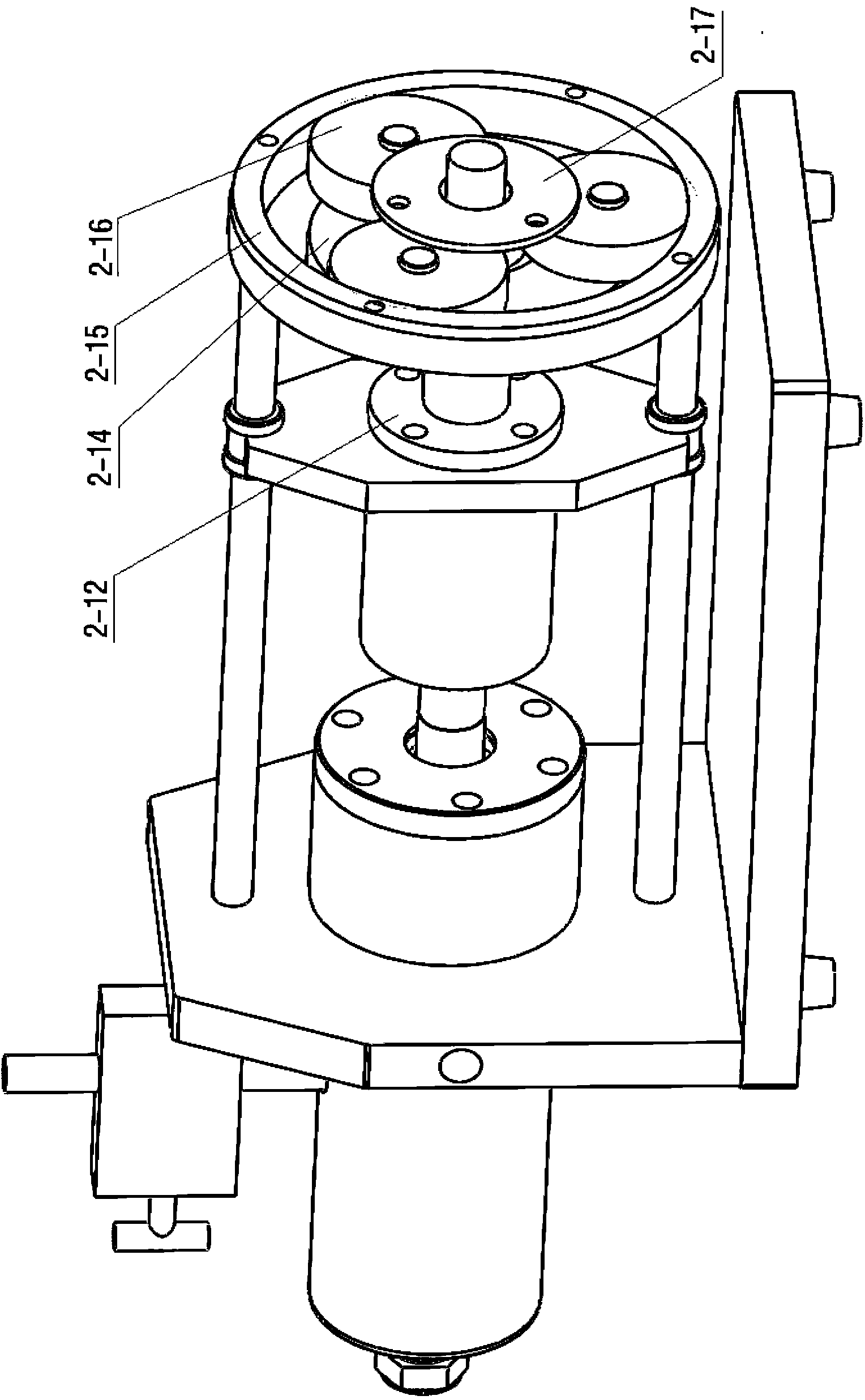

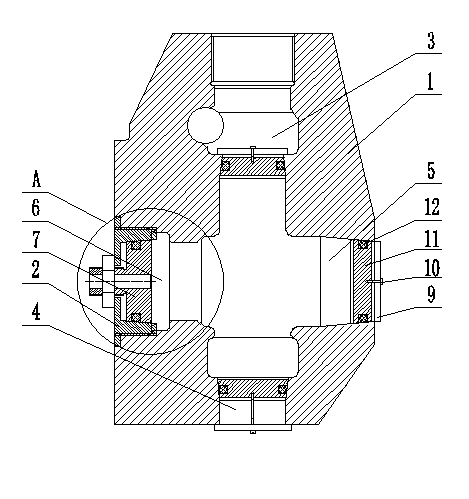

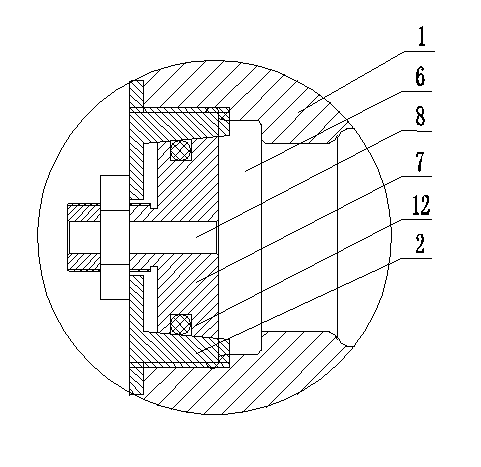

Pump head self-enhancing seal structure and self-enhancing device for pump head

InactiveCN103195699ASimple structureGuaranteed stabilityPump testingPositive displacement pump componentsHigh pressurePump head

The invention relates to a pump head self-enhancing seal structure and a self-enhancing device for a pump head, and belongs to the technical field of pump head self-enhancement. The pump head self-enhancing seal structure comprises an end cover, a high-pressure pump head, a discharge hole, a suction hole, a through hole and a plunger hole. The discharge hole, the suction hole, the through hole and the plunger hole are arranged in the high-pressure pump head in a cross manner. The end cover is mounted on an inner thread of the plunger hole of the high-pressure pump body. The self-enhancing device comprises a low-pressure unit and a high-pressure unit, and the low-pressure unit is connected with a water feed pipe of the high-pressure unit through an ultrahigh-pressure pressurizer. During self-enhancement of the pump body, the self-enhancing device can realize loading and pressure maintaining in the process of self-enhancement and pressurization of the pump body through adjustment of the low-pressure unit. The problems that requirements on accurate pressure adjustment, step-by-step loading, pressure maintaining and step-by-step unloading cannot be met by an existing self-enhancing device for the pump head can be solved. A preset elastic-plastic deformation of the high-pressure pump head can be realized, and the purpose of improving fatigue strength of the high-pressure pump head can be achieved.

Owner:YANGTZE UNIVERSITY

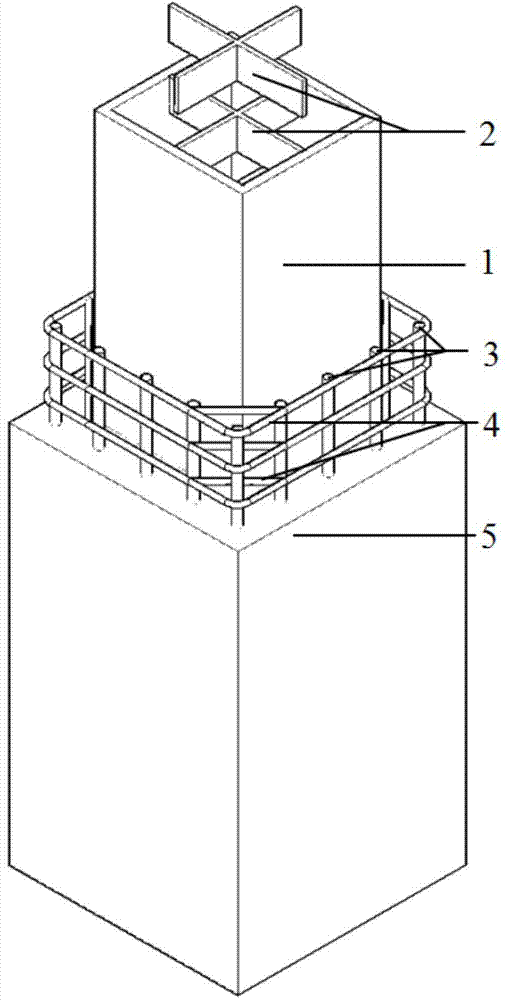

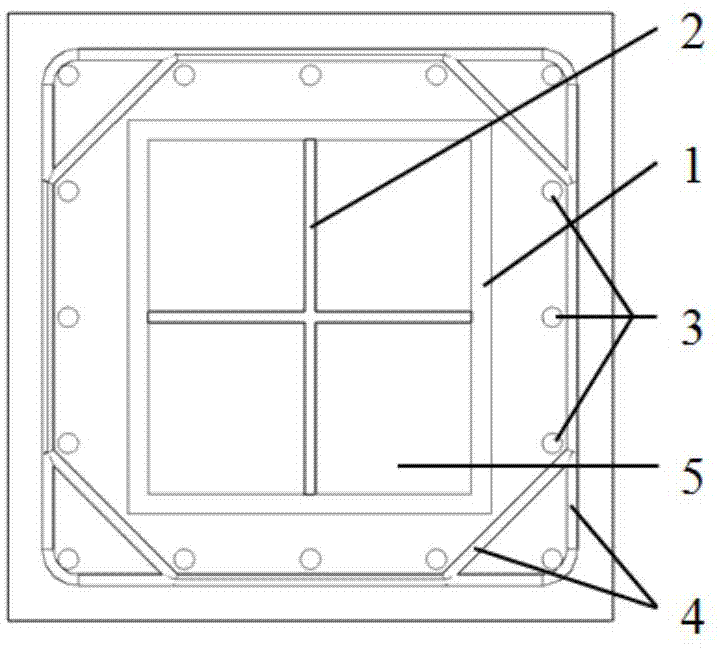

Box-type steel bone confined concrete column with cross constraint batten plates and fabrication method of column

ActiveCN103924741AIncrease binding forceConvenient bindingStrutsPillarsUltimate tensile strengthElastic plastic deformation

The invention relates to a steel bone concrete column, and particularly relates to a box-type steel bone confined concrete column with cross constraint batten plates. The box-type steel bone confined concrete column disclosed by the invention comprises a box-type steel bone, the cross constraint batten plates, longitudinal reinforcement, a composite stirrup and concrete, wherein the cross constraint batten plates are respectively welded and connected with steel plates at two opposite edges of the box-type steel box in the middles of the steel plates in a sectioning manner, so that the calculated length of each edge steel plate of the box-type steel bone is effectively reduced, the buckling deformation is constrained, and meanwhile, the inspection capability of internal concrete of the steel bone is enhanced by existence of the cross constraint batten plates. The cross constraint batten plates are arranged at intervals, so that the pouring quality of the concrete is ensured when the edge steel plates of the box-type steel bone are constrained. Therefore, the concrete disclosed by the invention has the relatively high strength and good elastic-plastic deformation capacity, and the formed steel bone concrete column has the relatively hhigh bearing capacity, ductility and energy-dissipating capacity.

Owner:BEIJING UNIV OF TECH

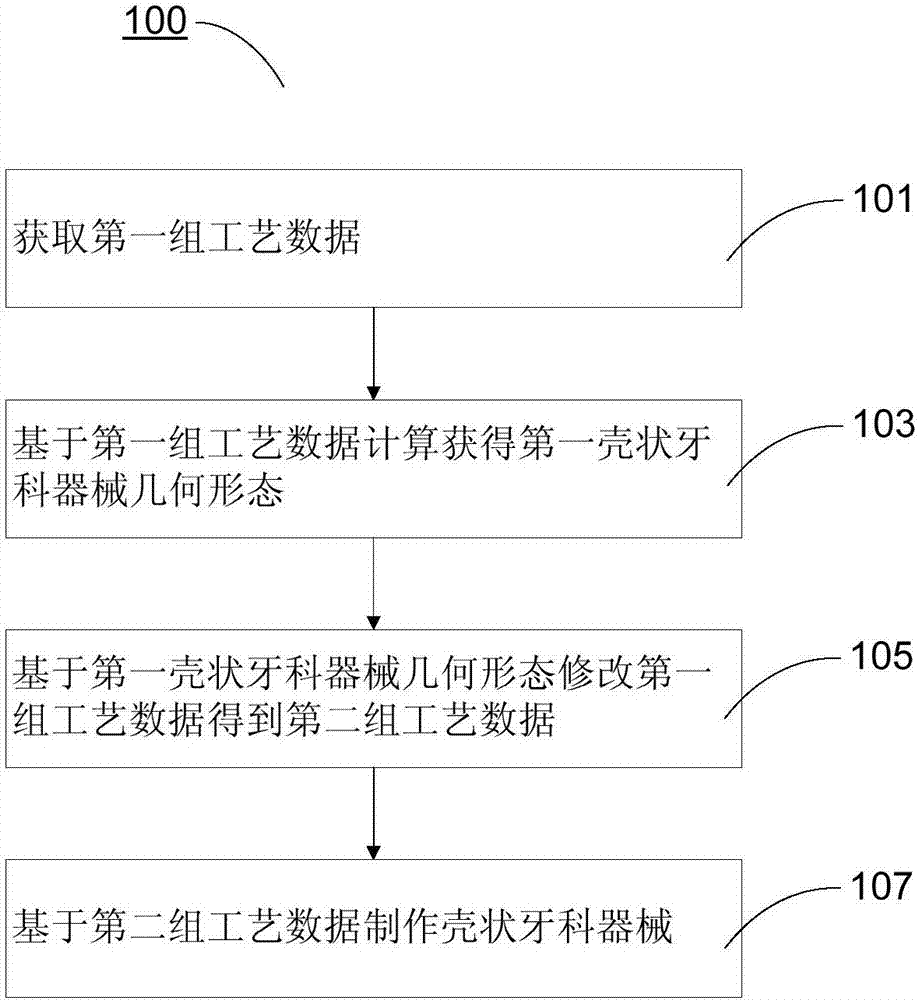

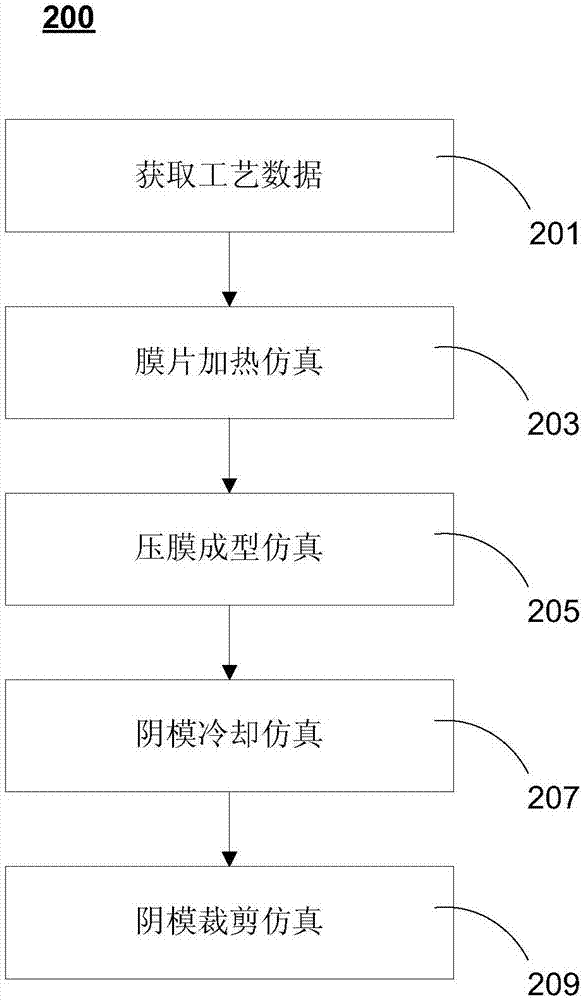

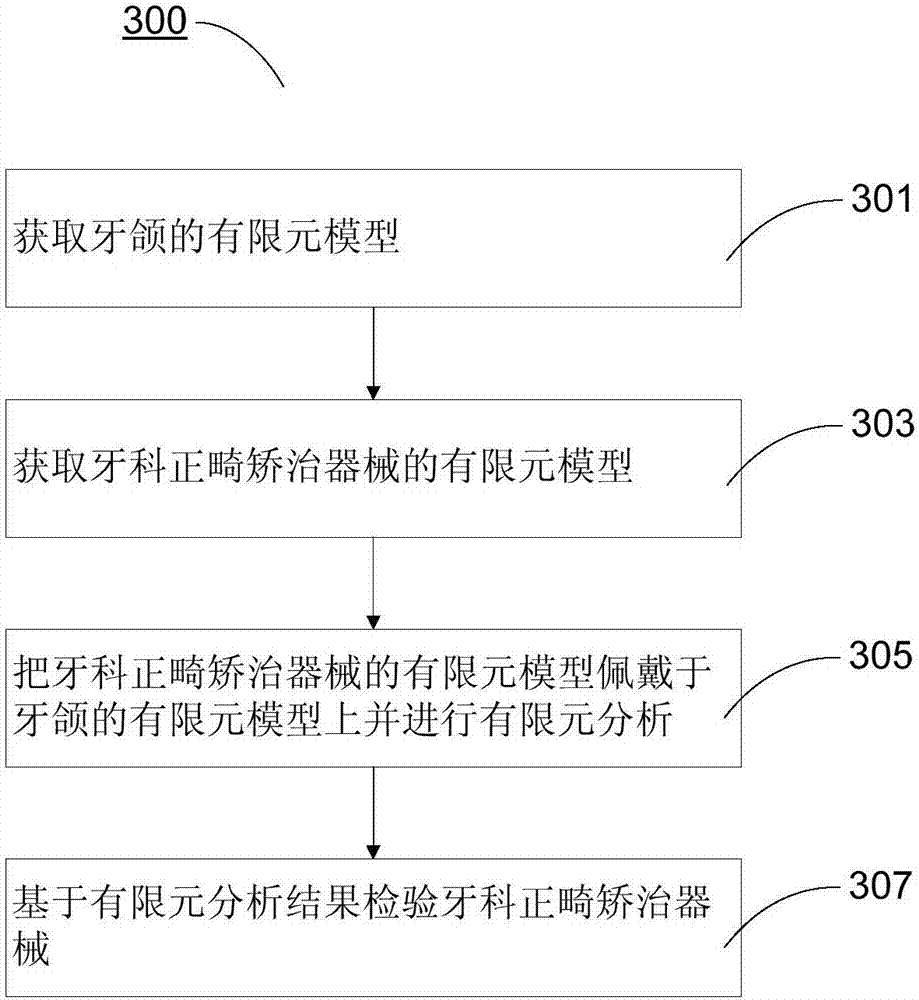

Process data optimization method of shell-shaped dental appliance making process based on hot-pressing film molding technology

ActiveCN107357949AOthrodonticsDesign optimisation/simulationComputer scienceElastic plastic deformation

The invention provides a process data optimization method of a shell-shaped dental appliance making process based on the hot-pressing film molding technology. The process data optimization method comprises obtaining a first set of process data of the shell-shaped dental appliance making process based on the hot-pressing film molding technology; obtaining a first shell-shaped dental appliance geometric shape through calculation based on the first set of process data; modifying the first set of process data based on the first shell-shaped dental appliance geometric shape in order to at least partially offset the deviation between the first shell-shaped dental appliance geometric shape and the design and caused by elastic-plastic deformation in the shell-shaped dental appliance making process, and obtaining a second set of process data.

Owner:WUXI EA MEDICAL INSTR TECH

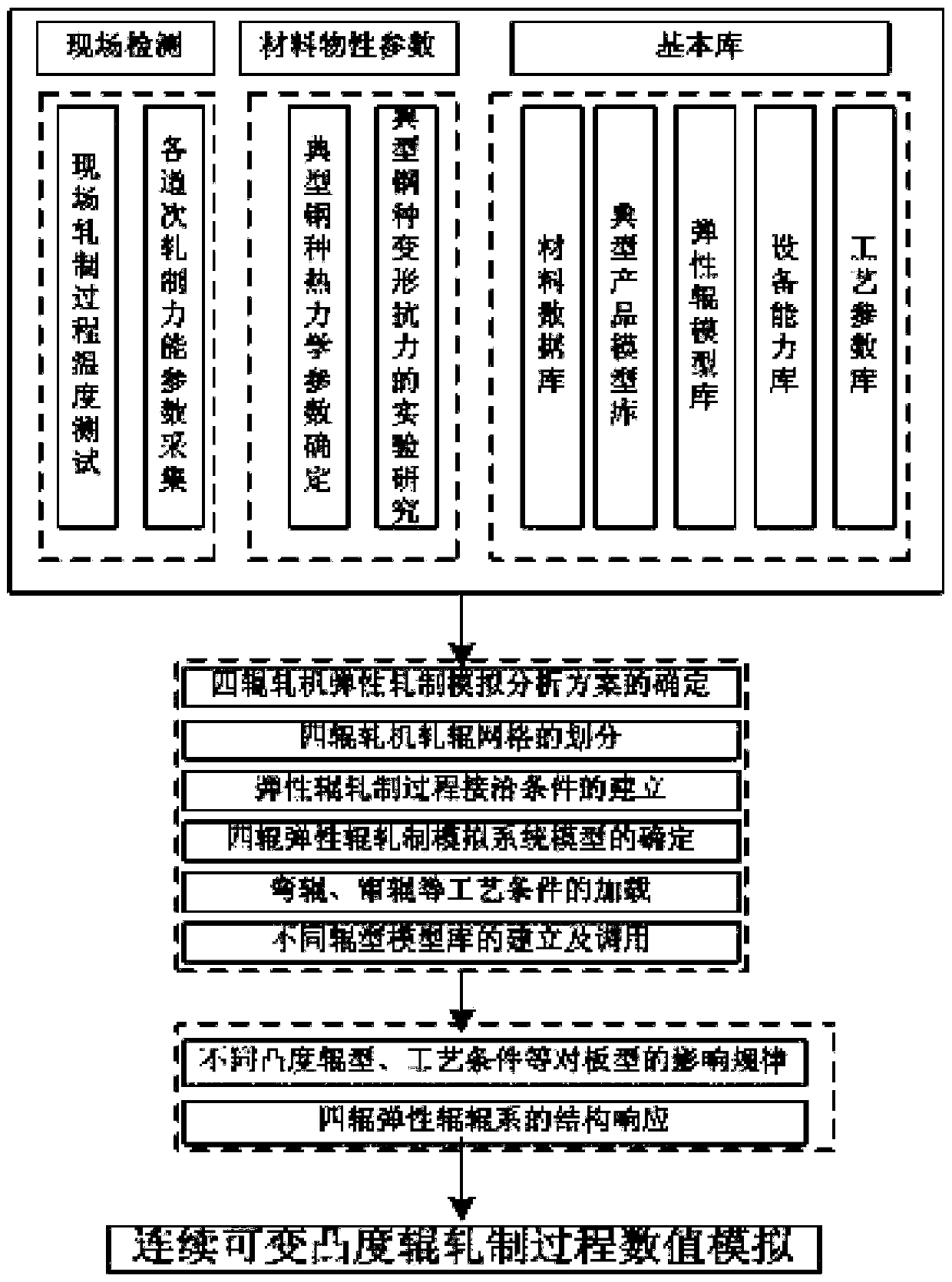

Numerical simulation method for rolling process deformation of continuous variable convexity roller of wide and thick plate product

PendingCN110008572AImprove impactExtend your lifeGeometric CADDesign optimisation/simulationElement modelElement analysis

The invention discloses a numerical simulation method for deformation in the rolling process of a continuous variable convexity roller of a wide and thick plate product. The numerical simulation method comprises the following steps: obtaining material attribute parameters of the continuous variable convexity roller and a rolled piece; determining geometric parameters of the continuous variable convexity roller and rolled piece; establishing a geometric model of the continuous variable convexity roller and rolled piece by utilizing three-dimensional drawing software; obtaining process parameters of rolled piece rolling forming and continuous variable convexity roller deformation; establishing a three-dimensional thermal coupling finite element analysis model; carrying out simulation analysis of deformation in the rolling process of the continuous variable convexity roller; and verifying the correctness of the three-dimensional thermal coupling finite element model. Accuracy and reliability of the model are guaranteed, elastic deformation of the continuous variable convexity roller and elastic-plastic deformation of a rolled piece are coupled together, and compared with other technologies, in addition, by means of coupling of a temperature field and a stress field, the method better conforms to the actual situation. The method is simple and easy to implement, low in cost, high inprecision and efficiency and capable of replacing a trial-manufacture experiment in practice.

Owner:SD STEEL RIZHAO CO LTD

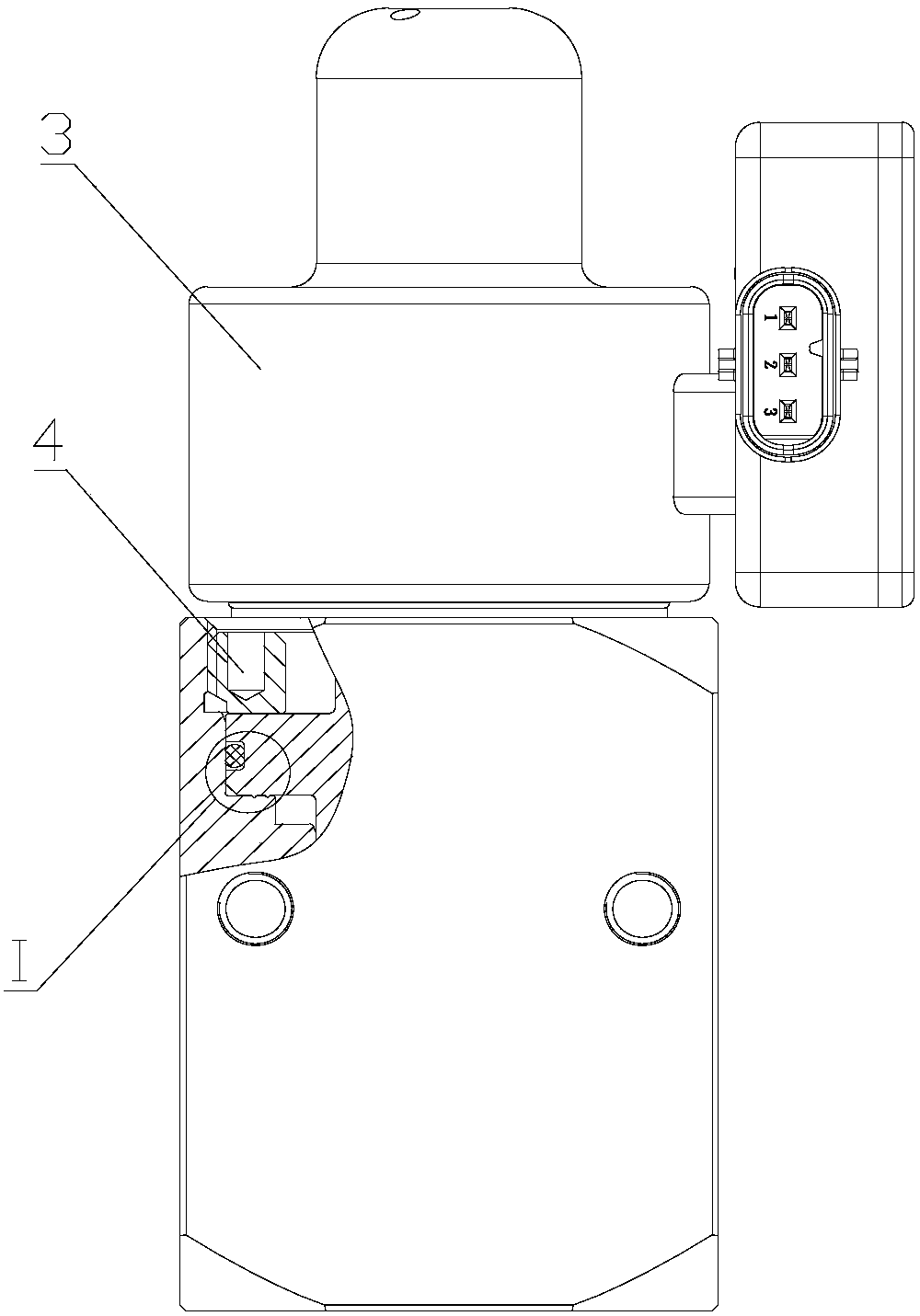

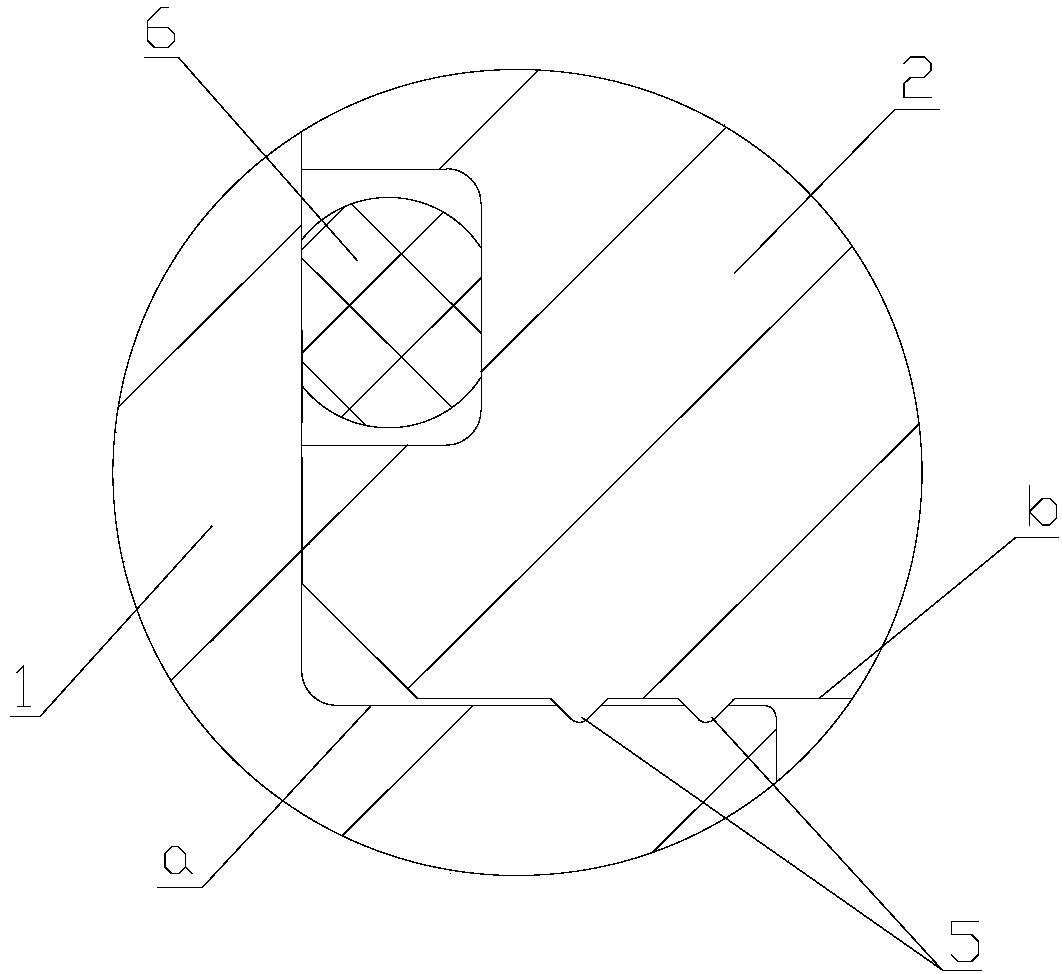

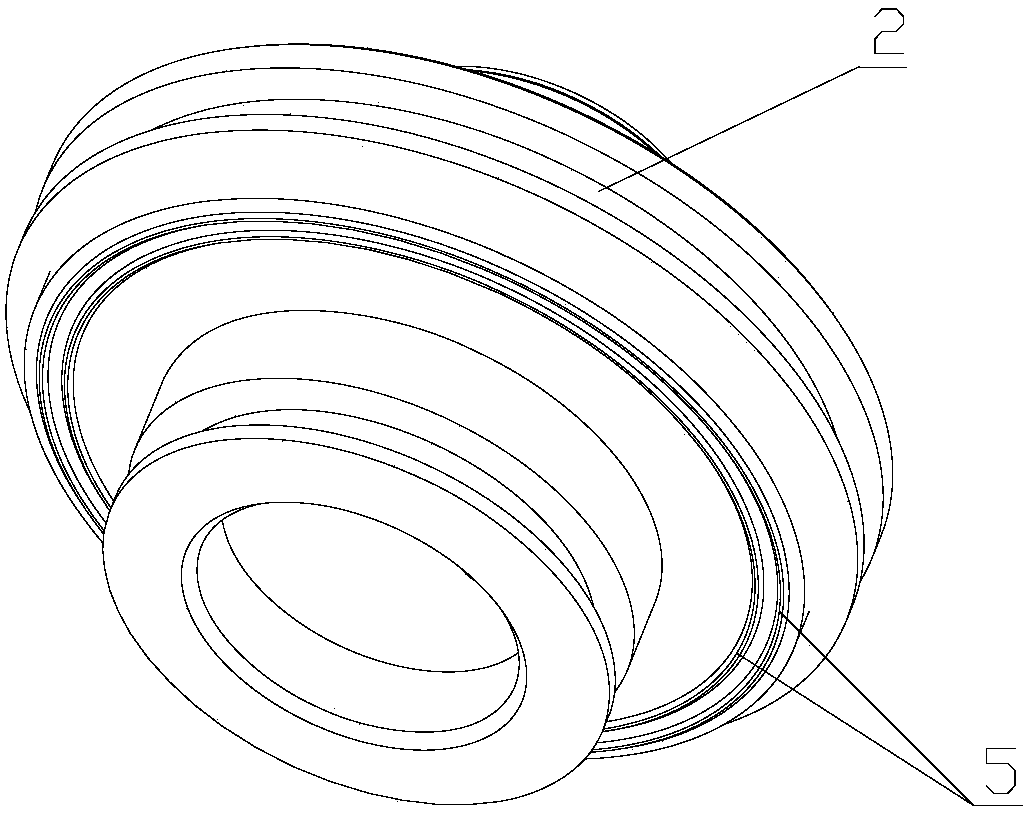

Electromagnetic valve

InactiveCN108087605AAchieving tightnessImprove applicabilityValve housingsSolenoid valveWorking pressure

The invention discloses an electromagnetic valve. The electromagnetic valve comprises a valve body (1) and a valve base (2); the valve body (1) is provided with a first sealing surface; the valve base(2) is provided with a second sealing surface; the first sealing surface and / or the second sealing surface are provided with at least one annular projection (5) projected on the first sealing surfaceand / or the second sealing surface; through a pressing part, the valve base and the valve body are mutually pressed and butted; the annular projection (5) is embedded in the butted second sealing surface and / or the first sealing surface under the effect of pressing force; and hard sealing is formed between the first sealing surface and the second sealing surface. The electromagnetic valve achievesthe sealing purpose through elastic plastic deformation between two parts, needing to be sealed, through external force; and the sealing structure can bear higher working temperature and higher working pressure, so that stable and reliable work in a carbon dioxide vehicle air conditioning system can be achieved.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

Batten plate constraint type confined concrete column with cross steel bone with flanges and fabrication method of column

InactiveCN103924735AConstrained buckling deformationReduce own overhangStrutsBuilding material handlingUltimate tensile strengthElastic plastic deformation

The invention relates to a steel bone concrete column, and particularly relates to a batten plate constraint type confined concrete column with a cross steel bone with flanges. The batten plate constraint type concrete column disclosed by the invention comprises the cross steel bone with the flanges, constraint batten plates, longitudinal reinforcement, a composite stirrup and concrete, wherein the constraint batten plates are respectively welded and connected with two adjacent flanges of the cross steel bone with the flanges in a sectioning manner, so that free extension length of each flange is effectively reduced, buckling deformation of the flanges is constrained, meanwhile, the inspection capability of internal concrete of the steel bone is enhanced by existence of the constraint batten plates. The constraint batten plates are arranged at intervals, and the internal part of the steel bone is communicated with external concrete in series, so that the pouring quality of the concrete is ensured. Therefore, the concrete disclosed by the invention has the relatively high strength and the good elastic-plastic deformation capacity, and the formed steel bone concrete column has the relatively high bearing capacity, ductility and energy-dissipating capacity.

Owner:BEIJING UNIV OF TECH

Method for shot blasting on surface of wheel of passenger vehicle

InactiveCN101518889AImprove fatigue resistanceAccelerated corrosionAbrasive blasting machinesStress concentrationEngineering

The invention discloses a method for shot blasting on the surface of a wheel of a passenger vehicle. The method is characterized in that the wheel is suspended and hooked through a suspending chain and enters a shot blasting chamber; the distance between suspending hooks is 800 millimeters; the moving speed of the suspending hooks is between 0.5 and 3 meters / minute frequency control; eight shot throwing machines are adopted; the shot throwing amount is 8*280 kilograms / minute; the diameter of a steel shot is 0.8 millimeter; the shot blasting time of each piece is 0.6 minute; each surface of the wheel can be impacted from the direction of 360 degrees so that the surface of the wheel produces elastic and plastic deformation and shows higher residual compressive stress so as to improve the surface strength and fatigue strength of a material of a surface layer of the wheel and the punched edge angle burr of the edge of a radiating hole, a center hole and a bolt hole of the wheel is passivated so as to avoid stress concentration. In the process of shot blasting, the surface layer of the material bears severe impact of the steel shot to produce a strain-hardening layer, thereby causing two effects: 1, the subgrain thinning caused on a tissue and the increase of dislocation density; and 2, the introduction of high macroscopic residual stress. Moreover, for the impact of the steel shot, the surface roughness is increased so that sharp edge produced in processing tends to smoothness. The changes obviously improve fatigue resistance and stress corrosion resistance of the material, thereby obviously improving the service life of the wheel; and the treatment method is validated and obtains excellent effect and economic benefit in production practice of our company.

Owner:山东通力车轮有限公司

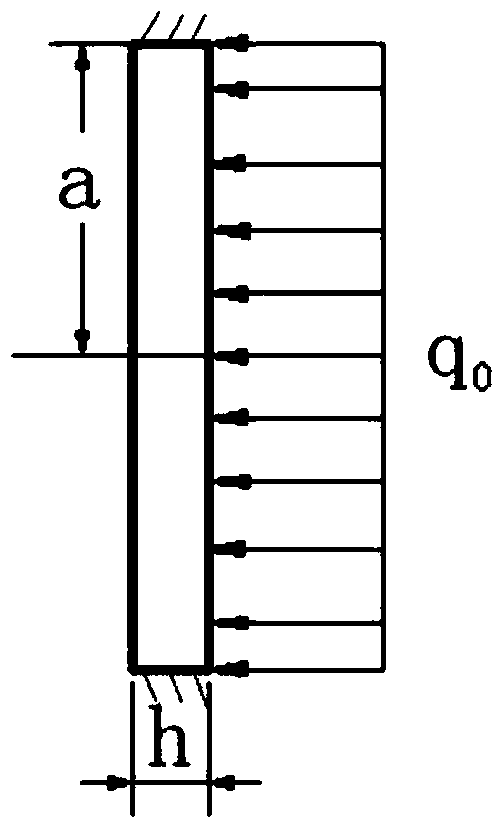

Large-span high-load prestressing force groove-shaped composite plate used as top plate of anti-aircraft basement

The invention discloses a large-span prestressing force groove-shaped composite plate used as a top plate of an anti-aircraft basement of 6 grades and lower than 6 grades. The composite plate is characterized in that a groove-shaped composite plate with a large span, a high load, a narrow board width and a low rib height forms a functional member together with an upper composite layer. Due to the adoption of an elastic-plastic deformation resilience characterization coefficient of a prestressing force plate, the resistance of the member under the action of a short-term effect of a nuclear explosion shock wave is improved. Therefore, materials are substantially saved, and the floor height is reduced. A groove-shaped large load meets the using requirements of an underground garage; parking spaces are saved in a large span; due to the adoption of a groove-shaped narrow board, the manufacturing cost and the floor height can be reduced; and the composite plate has an appropriate rib height and can meet load bearing requirements and the requirement of forming an air channel on a rib, the floor height is not increased, and a groove-shaped horizontal air channel is easy to connect. When the composite plate is used for the top plate of the underground garage, a construction period can be accelerated, the floor height can be reduced, the manufacturing cost can be reduced, a column grid can be saved, the parking spaces can be increased, and the grade of the underground garage can be improved.

Owner:柳忠林

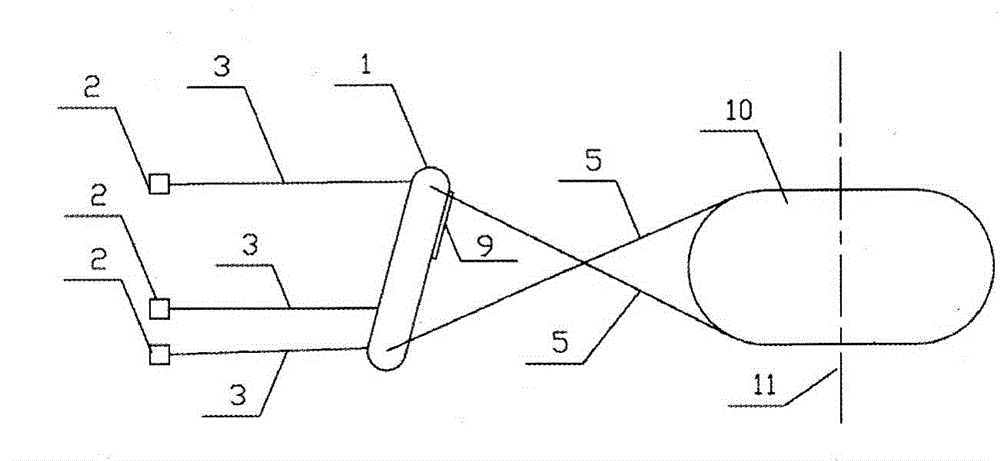

Flexible pile and gravity pier combined anti-collision device

InactiveCN101487245AReduce damageReduce repair workClimate change adaptationShipping equipmentEngineeringStructural engineering

The invention discloses an anti-collision facility which is arranged before a pier and consists of a flexible pile, a gravity pier and a rubber pad. The flexible pile is arranged at the front part and the gravity pier is arranged at the rear part; the flexible pile and the gravity pier are sequentially impacted by the ship, the impact time is prolonged by the elastic-plastic deformation of the flexible pile, the impact force of the ship finally transmitted to the gravity pier is relatively small, and the excessive deformation of the gravity pier is not caused, therefore, the recovery working quantity of the anti-collision facility is small and only the flexile pile is required to be replaced.

Owner:ENG COLLEGE OF ENG CORPS PLA UNIV OF SCI & TECH +1

Reinforcement type float cylinder type composite anti-collision device

InactiveCN106012978AHigh elastic-plastic deformation energyPromote absorptionClimate change adaptationBridge structural detailsElastomerSurface layer

The invention belongs to the anti-collision technical field. A reinforcement type float cylinder type composite anti-collision device is formed by connecting multiple float cylinder units. Each float cylinder unit comprises a hollow barrel-shaped surface layer and reinforcing ribs, wherein the surface layer comprises an outer layer, an inner layer and an elastomer filling layer arranged between the outer layer and the inner layer, and the reinforcing ribs are arranged in a hollow cavity of the surface layer. The reinforcement type float cylinder type composite anti-collision device has the beneficial effects that the structural form of a float cylinder is a hollow cylinder form, the structure is stable, and the cylinder structure is smaller in wave force compared with a rectangular structure and is suitable for bad wave environments with strong wave functions, uncertain wave directions and the like; and elastic-plastic deformation energy of an anti-collision structure is high so that energy absorption of an anti-collision block can be improved, and a bridge pier can be further protected. Meanwhile, installation is convenient, maintenance is simple, and the maintenance cost is low.

Owner:江苏天御海工新材料科技有限公司

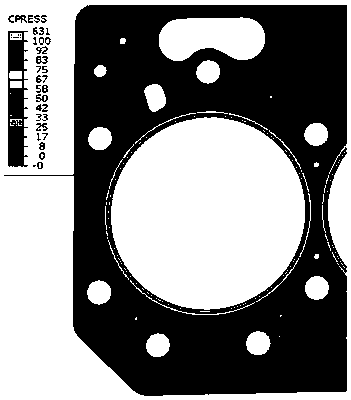

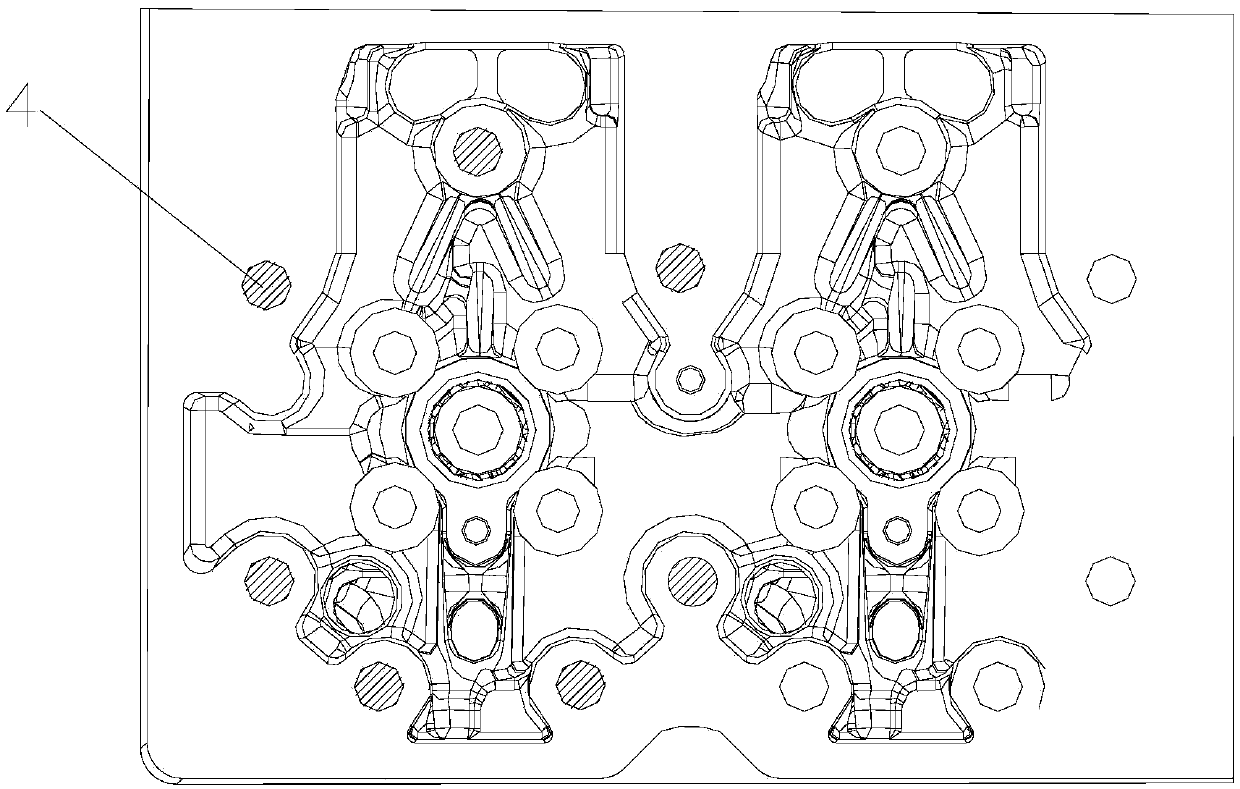

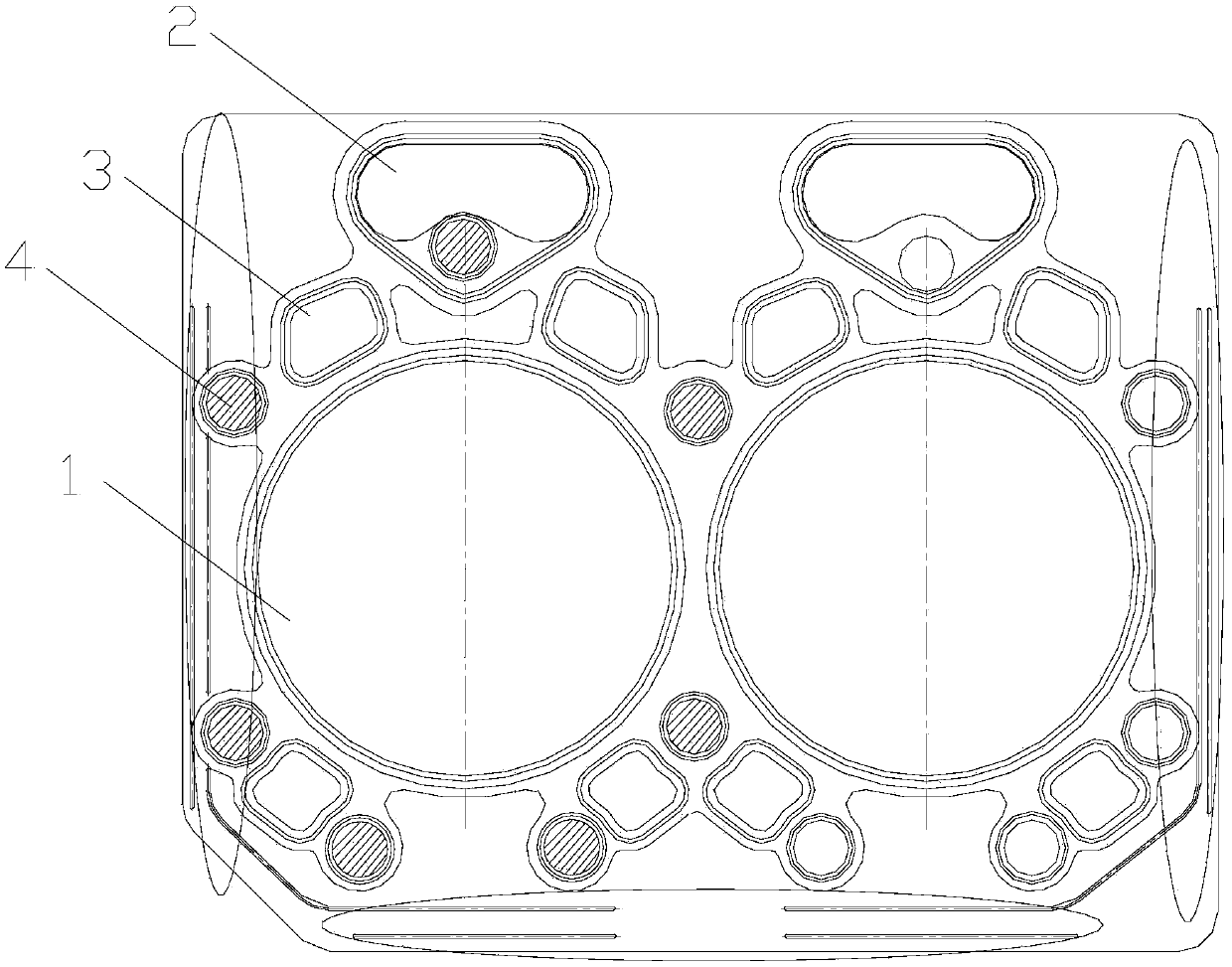

Gasket for solving cylinder cover sealing failure and estimating method of tightness of gasket

InactiveCN109630308AEven by forceMake up for air leaksSealing arrangements for enginesMachines/enginesElement analysisEstimation methods

The invention discloses a gasket for solving cylinder cover sealing failure and an estimating method of tightness of the gasket, and belongs to the technical field of engine fittings. N adjusting waves are added at the outer periphery, with more centralized bolts, of the gasket. The estimating method of the tightness of the gasket comprises estimation of elastic-plastic deformation performance ofthe gasket and estimation of sealing pressure of the gasket, wherein the estimating method of the sealing pressure of the gasket comprises the following steps: a calculating model is built; the material attributes of a machine body, a cylinder cover, a cylinder cover bolt and a gasket module are defined; the contact and the constraint among parts are built; and the sealing pressure distribution ofthe gasket is calculated by finite element analysis to determine if the sealing pressure of sealing strips in a cylinder port, a water hole and an oil hole on the cylinder cover gasket meets requirements or not. The estimation method of the elastic-plastic deformation performance of the gasket comprises the following steps: pressure wave characteristic curves of the adjusting waves in the gasketare obtained according to the stress and deformation conditions of the gasket; and then, the line pressure is converted to the surface pressure to obtain gasket pressure wave compression characteristic curve data and gasket pressure wave compression characteristic curves.

Owner:TIANJIN LOVOL ENGINES

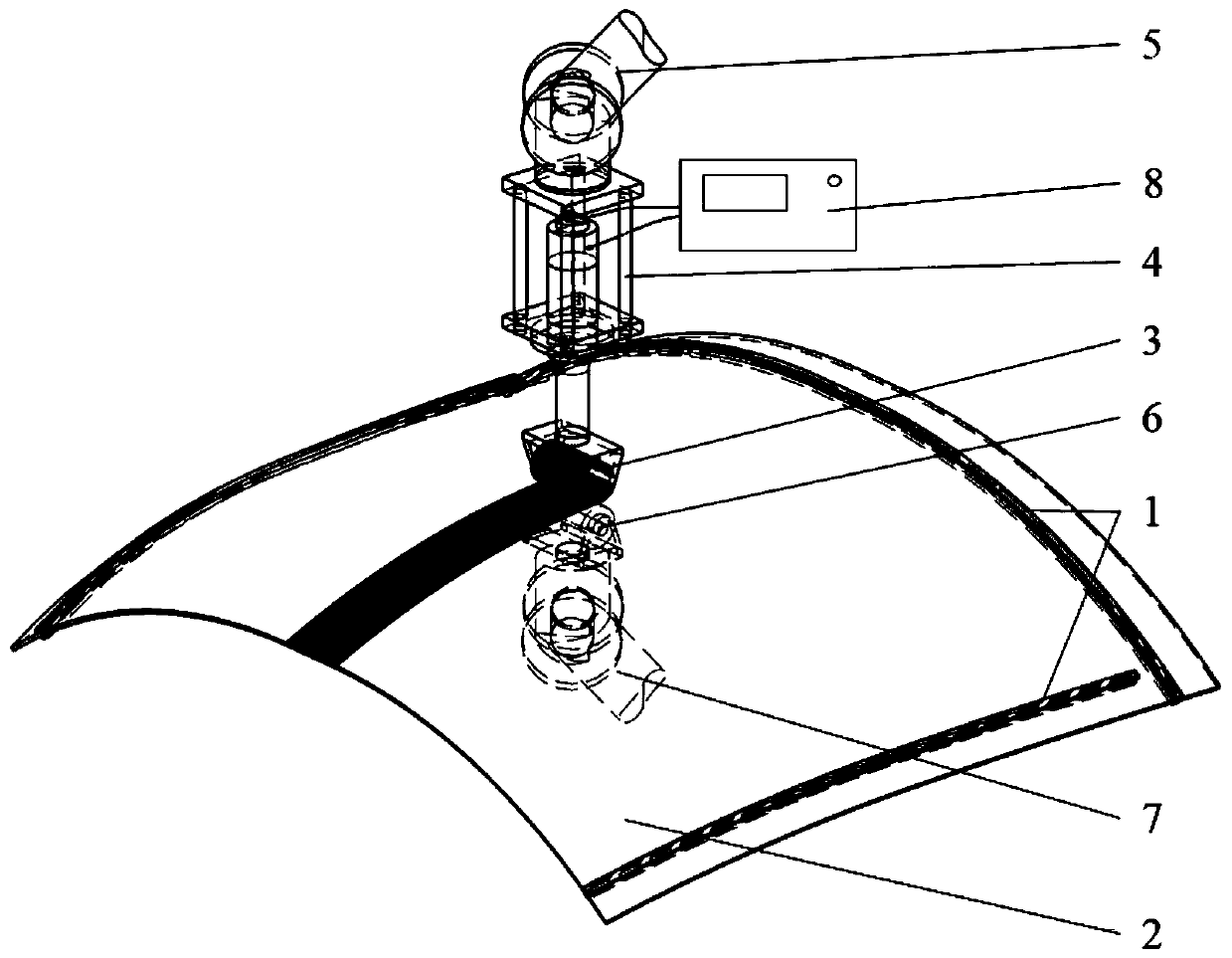

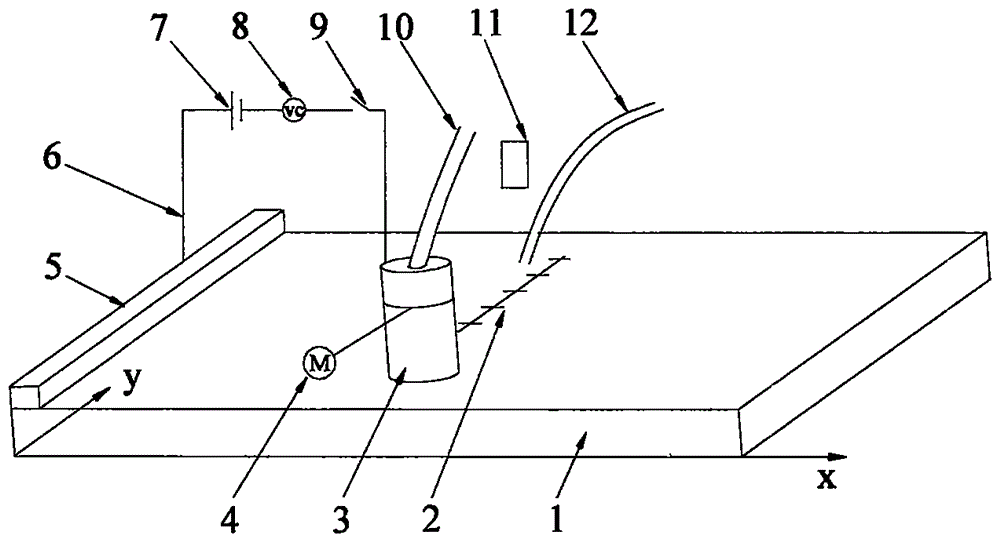

Ultrasonic-assisted flexible rolling forming method and device for micro-groove surface structure

ActiveCN110788182AHigh bonding strengthRealize continuous formingMetal-working feeding devicesMechanical vibrations separationEngineeringUltrasonic vibration

The invention belongs to the field of metal plastic forming, and discloses an ultrasonic-assisted flexible rolling forming method and device for a micro-groove surface structure. The device comprisesclamping sub-devices (1), an impression roller (3), a support roller (6) and an ultrasonic vibration system (4). The impression roller (3) and the support roller (6) can synchronously roll on the surface of a metal piece to be treated along a preset track, under the assistance of ultrasonic vibration, the impression roller and the support roller are cooperatively used to carry out extrusion effecton the metal piece to be treated, and then a micro groove is formed in the surface of the metal piece to be treated, wherein the ultrasonic vibration can soften the metal piece to be treated, and theauxiliary effect is achieved. According to the ultrasonic-assisted flexible rolling forming method, through improvement of the arrangement of the components in the device and the working relationshipof mutual cooperation between the components and the like, rolling extrusion on the surface of the metal plate piece is carried out through the cooperation of the impression roller and the support roller, so that the material on the surface of the metal plate piece is subjected to continuous elastic plastic deformation, and meanwhile, the deformation resistance of the material is reduced by utilizing the ultrasonic softening effect.

Owner:WUHAN TEXTILE UNIV +1

Groove-shaped steel plate shear wall with inbuilt round reinforcing cages and externally pasted steel plate supports and construction method

InactiveCN103883044AConstrained buckling deformationImprove the stable bearing capacityWallsShock proofingIn planeSheet steel

The invention relates to a composite steel plate shear wall, in particular to a groove-shaped steel plate shear wall with inbuilt round reinforcing cages and externally pasted steel plate supports and a construction method. The groove-shaped section adapts to the arrangement form of the shear wall in a building structure. As the inner sides of two steel plates are filled with concrete, buckling deformation of the steel plates can be effectively restricted, and the bearing capacity of the steel plates is improved. The concrete on the interior is double restricted by the steel plates on the two sides, cavity-dividing partition plates and the round reinforcing cages, so that the elastic-plastic deformation capacity and the ultimate compressive strength of the concrete are enhanced. The steel plate supports can fully play a role of diagonal draw bars and provide high resistant-lateral rigidity and a large bearing capacity for the shear wall. The flange parts of the shear wall with the groove-shaped section play a good role in restricting the web wall, so that the in-plane and out-plane bearing capacity of the composite shear wall is remarkably improved. Accordingly, the composite steel plate shear wall has the high bearing capacity and the good elastic-plastic deformation capacity.

Owner:BEIJING UNIV OF TECH

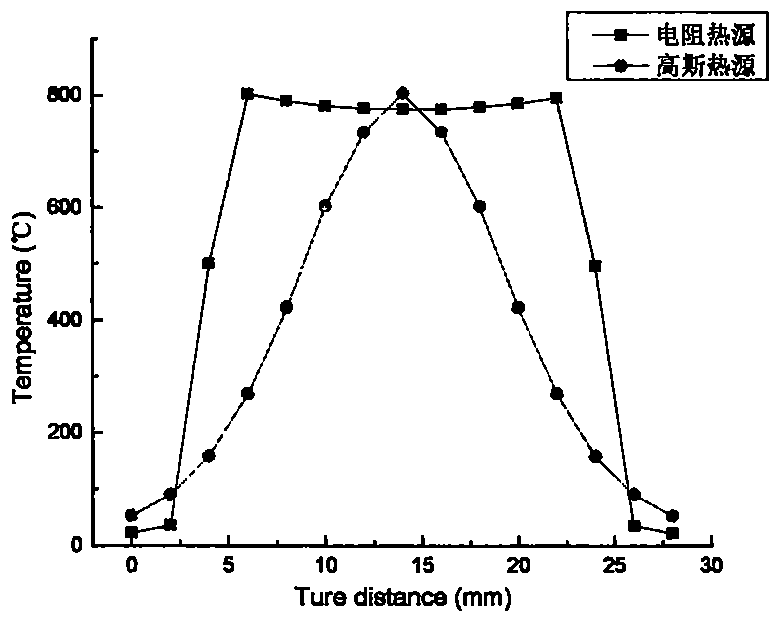

Line heating board bending forming technology method

The invention discloses a line heating board bending forming technology method. According to the technical scheme, a current passes through boards through one electrode and passes through the other electrode to form a loop, the gradient current density is formed in the thickness direction, and the problem that at present, during whole heat treatment of a large-width tailored welding blank, performance cannot be optimum is solved. The method comprises the following steps: firstly, the electrodes make contact with the metal boards, and the boards include a steel board, an aluminum alloy board, high-strength steel and a titanium alloy; secondly, a power source is powered on, the current passes through the metal boards through one electrode and passes through the other electrode to form the loop, and the current density is gradually reduced from top to bottom in the thickness direction; thirdly, the electrodes move relative to the metal boards, and move according to the reserved heating line, and resistance heat is used for locally heating the boards; fourthly, metal is heated to expand to have elastic plastic deformation, and angular deformation is formed; and fifthly, the heated portion is subject to tracking cooling, and in the elastic plastic deformation, elastic deformation is restored to plastic deformation, and angular deformation is reserved.

Owner:HARBIN INST OF TECH AT WEIHAI

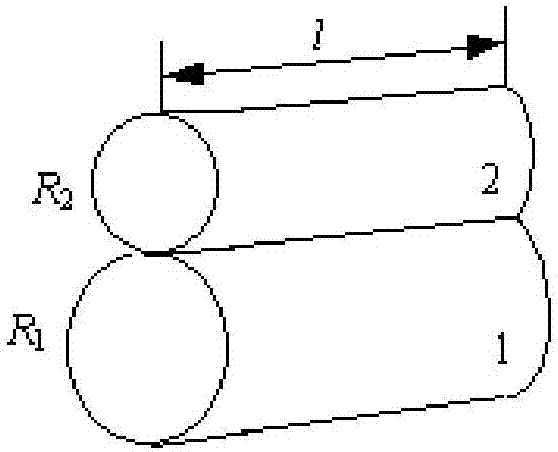

A calculating method for determining the interfacial rigidity of cylinders

InactiveCN107169200AEasy to operateControl dynamicsGeometric CADDesign optimisation/simulationHardnessEngineering

The invention relates to the field of dynamic analysis of mechanical interfaces and specifically relates to a calculating method for determining the interfacial rigidity of cylinders. The method specifically takes into consideration the influence of change of rigidity of contact materials along with surface loading depth, a friction coefficient in contact and elastic-plastic deformation of micro-bulges; the contact rigidity of a whole cylinder loaded interface contains elastic loads and elastic-plastic loads of all micro-bulges on the interface; the contact rigidity of cylinder interfaces is calculated by using the formula (described in the specification). The method is used for obtaining interfacial rigidity of cylinders of precision machinery. The calculating method is simple and easy to operate, enables interfacial rigidity of cylinders, which is hard to detect, to be obtained easily, overcomes the shortcomings of traditional methods, guarantees accuracy and reliability of results, and provides technical reference for controlling dynamic characteristics of cylinder interfaces.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com