Box-type steel bone confined concrete column with cross constraint batten plates and fabrication method of column

A technology of confining concrete and cross shape, applied in the directions of columns, piers, pillars, etc., can solve the problems of the reduction of the restraint capacity of steel reinforced concrete, the reduction of bearing capacity of steel-concrete columns, and the instability, so as to reduce maintenance costs and constraints. The effect of enhanced capacity and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

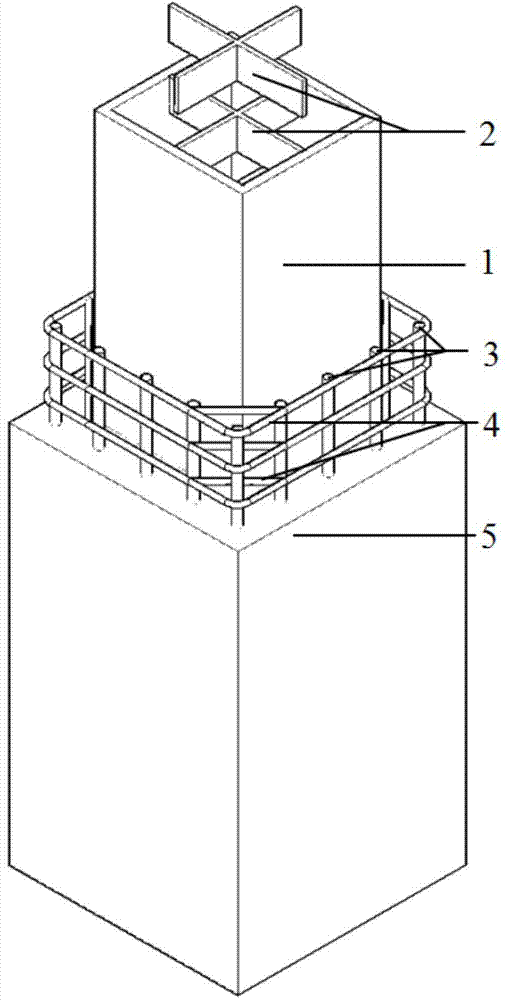

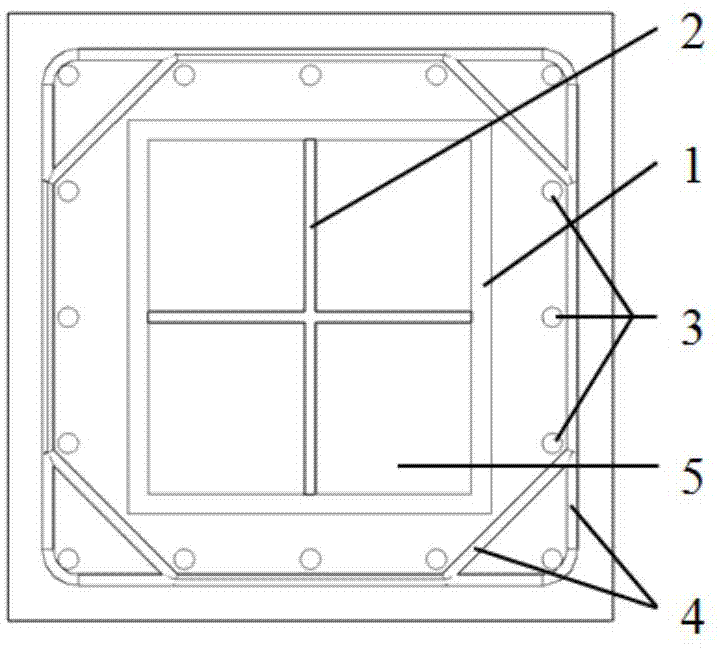

[0028] Such as figure 1 , figure 2 As shown, the box-shaped steel-frame-confined concrete column with cross-shaped restraint panels includes box-shaped steel frames 1, cross-shaped restraint panels 2, longitudinal steel bars 3, composite stirrups 4, and concrete 5; The steel-reinforced concrete column base is formed by adding a cross-shaped restraint panel.

[0029] According to the technical solution of the present invention, the manufacturing steps of the box-shaped steel-reinforced concrete column with cross-shaped constrained panels are as follows:

[0030] 1) Factory prefabricated welded box-shaped steel frame 1;

[0031] 2) Position the cross-shaped restraint plate 2 and weld it with the side steel plate of the box-shaped steel frame 1;

[0032] 3) After the prefabricated and welded steel frame members are transported to the site and positioned, the longitudinal reinforcement 3 and the composite stirrup 4 are bound;

[0033] 4) Support the formwork and pour concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com