Method for equivalence hinged corrugated pipe by coupled variable cross-section beam

A technology of variable cross-section beams and design methods, which can be used in calculations, special data processing applications, instruments, etc., and can solve problems such as difficulty in calculation and debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

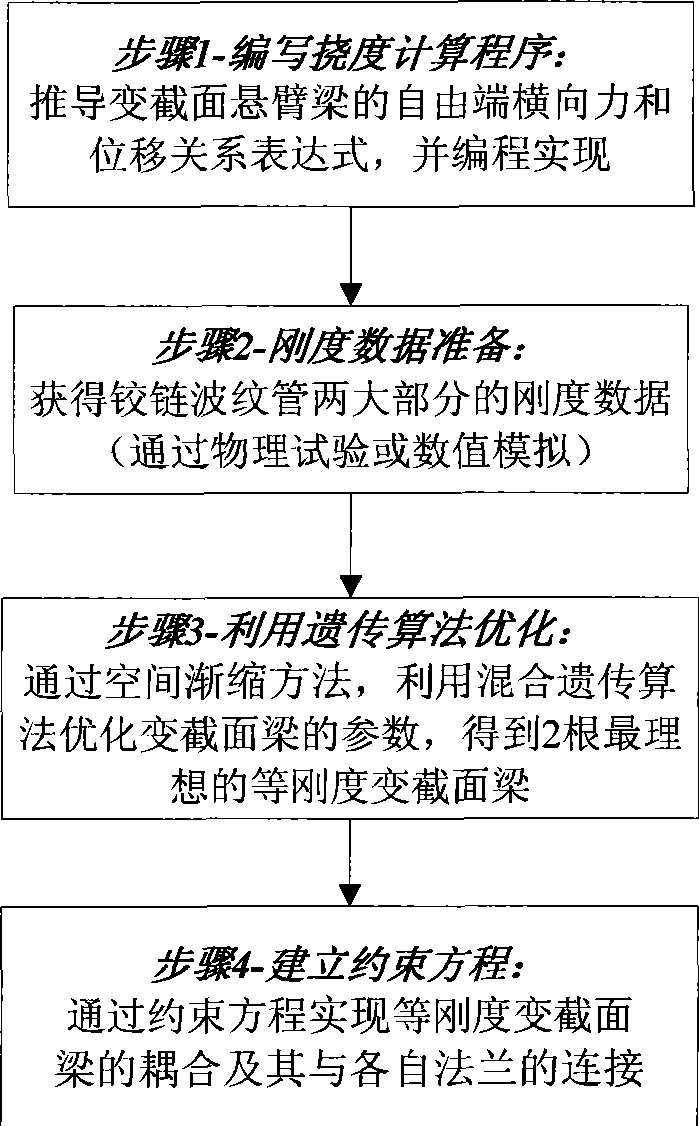

[0079] as attached figure 1 According to the steps of implementing the invention, the present invention includes the following four parts: 1) deriving the expression of the relationship between the lateral force and the displacement at the free end of the variable-section beam of the cantilever; 2) simplifying the hinged bellows, and obtaining the real Stiffness data of the two parts of the hinge bellows; 3) Using the hybrid genetic algorithm to optimize the parameters of each variable-section beam to obtain two variable-section beams with equal stiffness in the transverse direction; 4) Given the coupling of the variable-section beam and its connection with the flange method. The following four parts are introduced respectively.

[0080] 1 The relationship between lateral force and displacement of beam with small deflection and variable cross-section

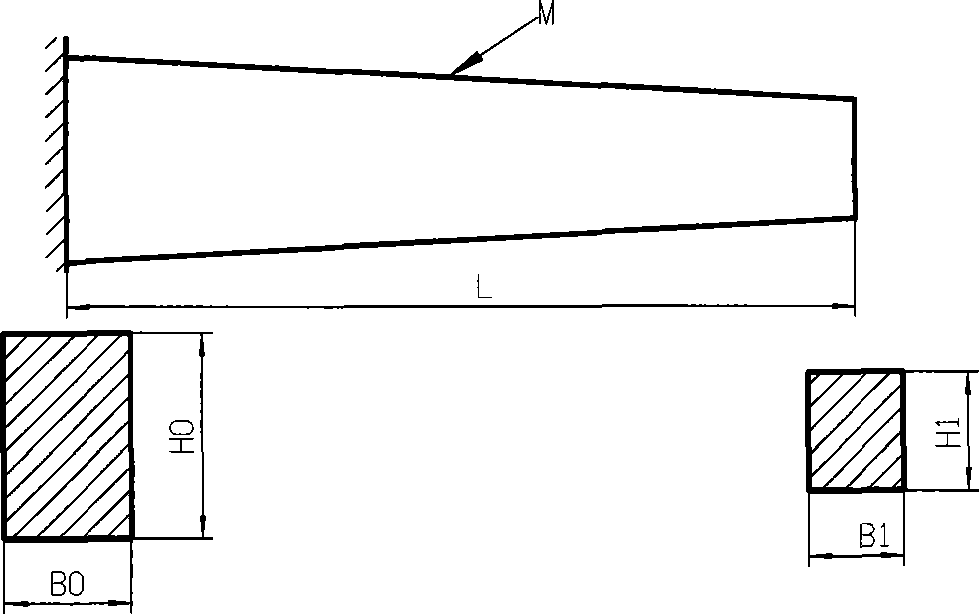

[0081] 1.1 Geometric parameters of variable cross-section beams

[0082] Instructions attached figure 2 Five geometric p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com