Gasket for solving cylinder cover sealing failure and estimating method of tightness of gasket

A sealing failure and gasket technology, which is applied to engine sealing devices, instruments, electrical digital data processing, etc., can solve the problems of increased gasket cost, long gasket development cycle, and uneven distribution of sealing pressure, so as to reduce the test cost , shorten the development cycle, and the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

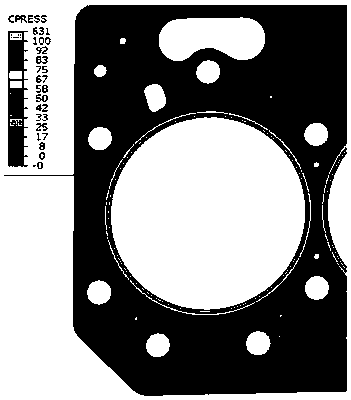

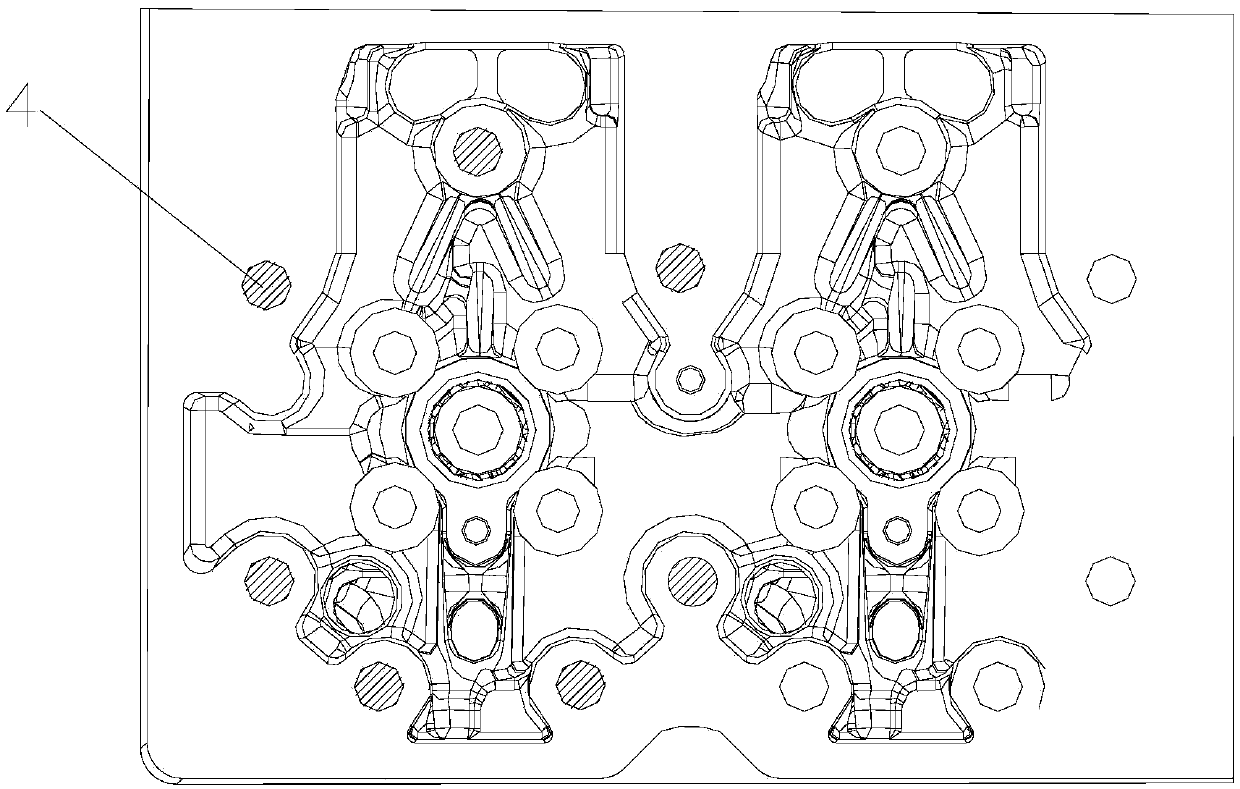

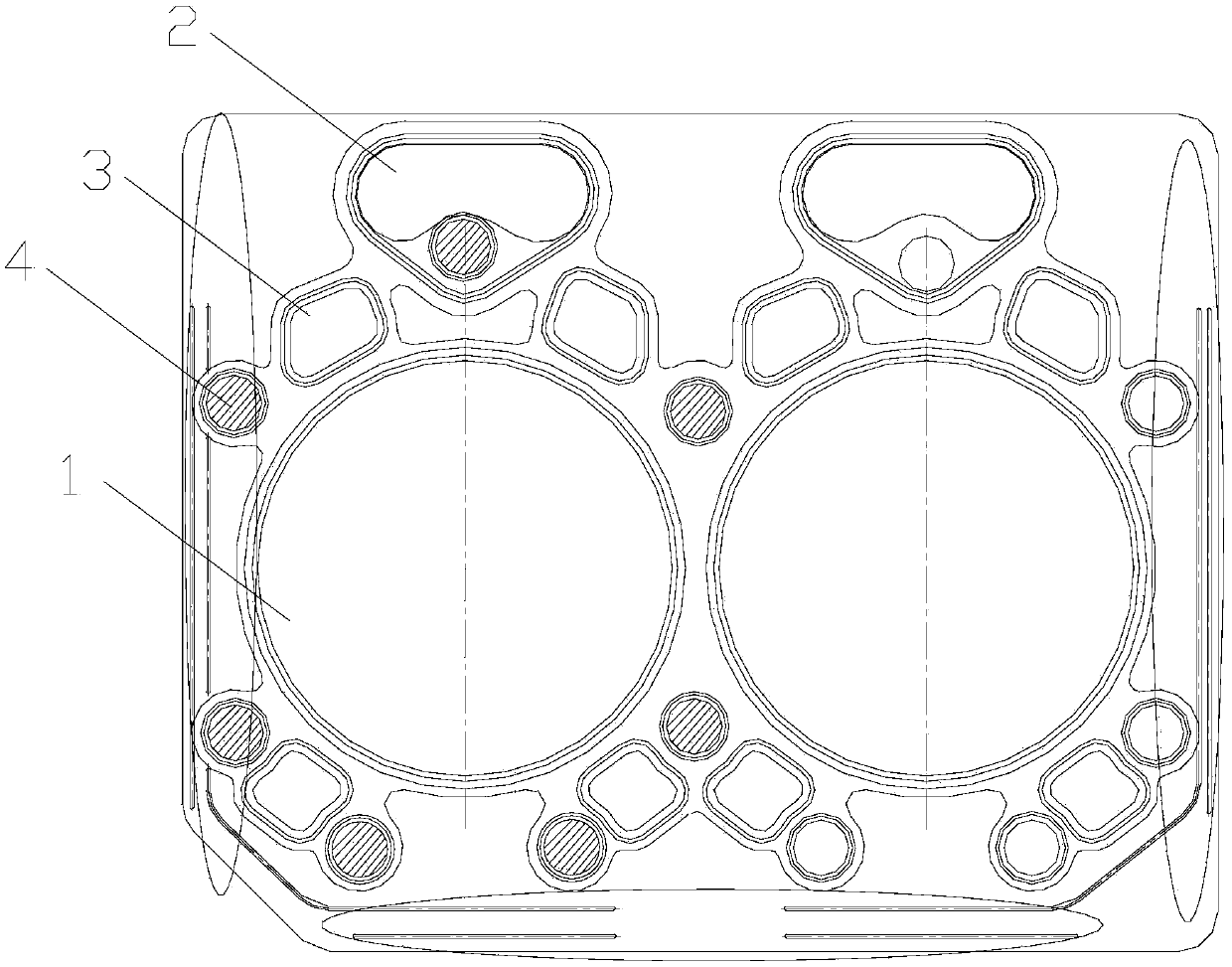

[0035] The current engine cylinder head gasket is mainly designed to add a sealing band around the seal (such as cylinder port, oil hole, water hole) for sealing. It is easier to achieve sealing when the cylinder head bolts are evenly arranged. If the bolts are arranged Unevenness will result in uneven stress on the bolts on both sides of the gasket, e.g. figure 1 As shown in , there are 4 bolts shown in the shaded part below the gasket, and 3 bolts shown in the shaded part above the gasket. Since the tightening torque of each cylinder head bolt is the same, that is, the axial force generated by each bolt It is the same, the total force of 4 bolts of bolts 1#-4# is greater than the total force of 3 bolts of bolts 5#-7#, resulting in uneven force on both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com