Self-damage energy-consuming repairable plastic hinge

A technology of plastic hinges and energy-consuming units, which is applied to building components, earthquake resistance, building types, etc., can solve the problems of irreparable, plastic hinge damage, and difficult realization, and achieve the effect of low cost, simple structure, and large deformation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

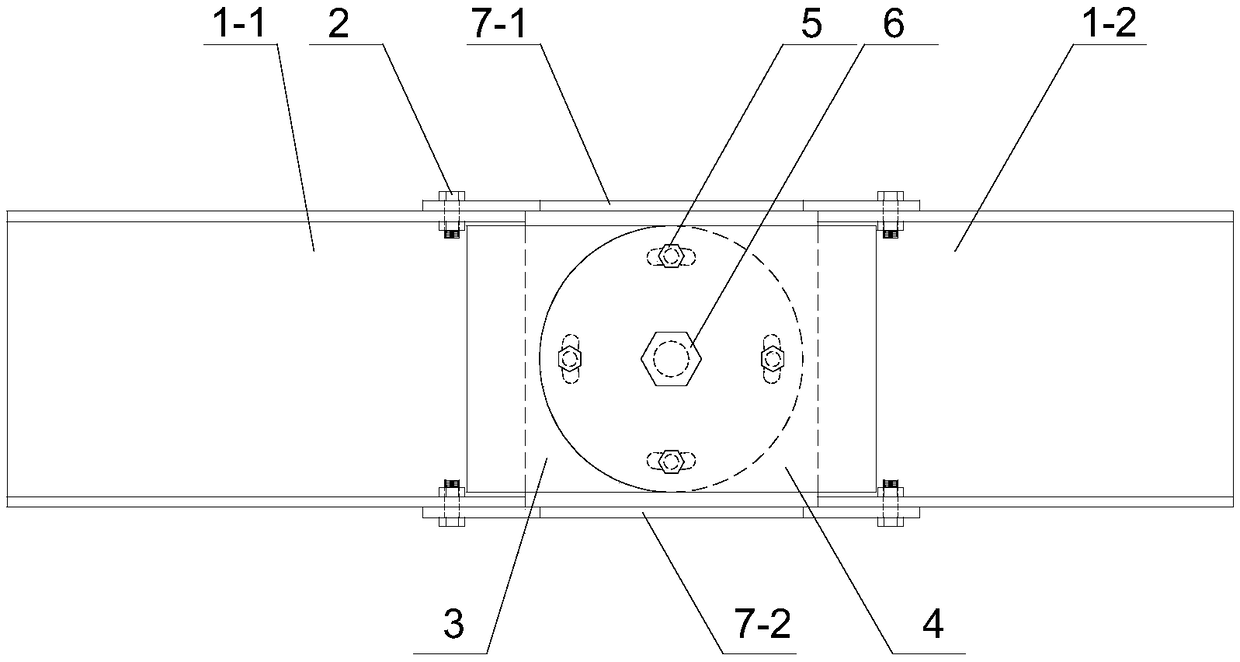

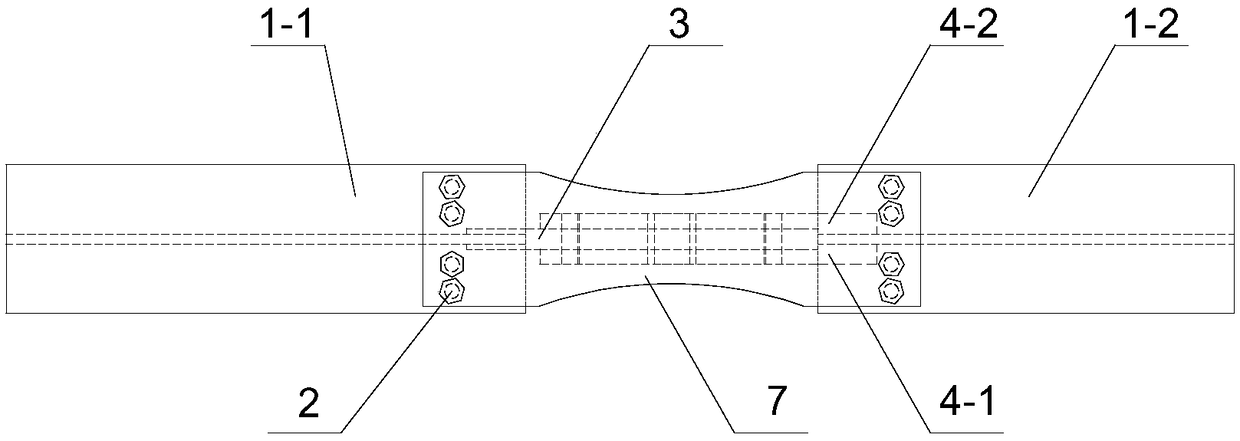

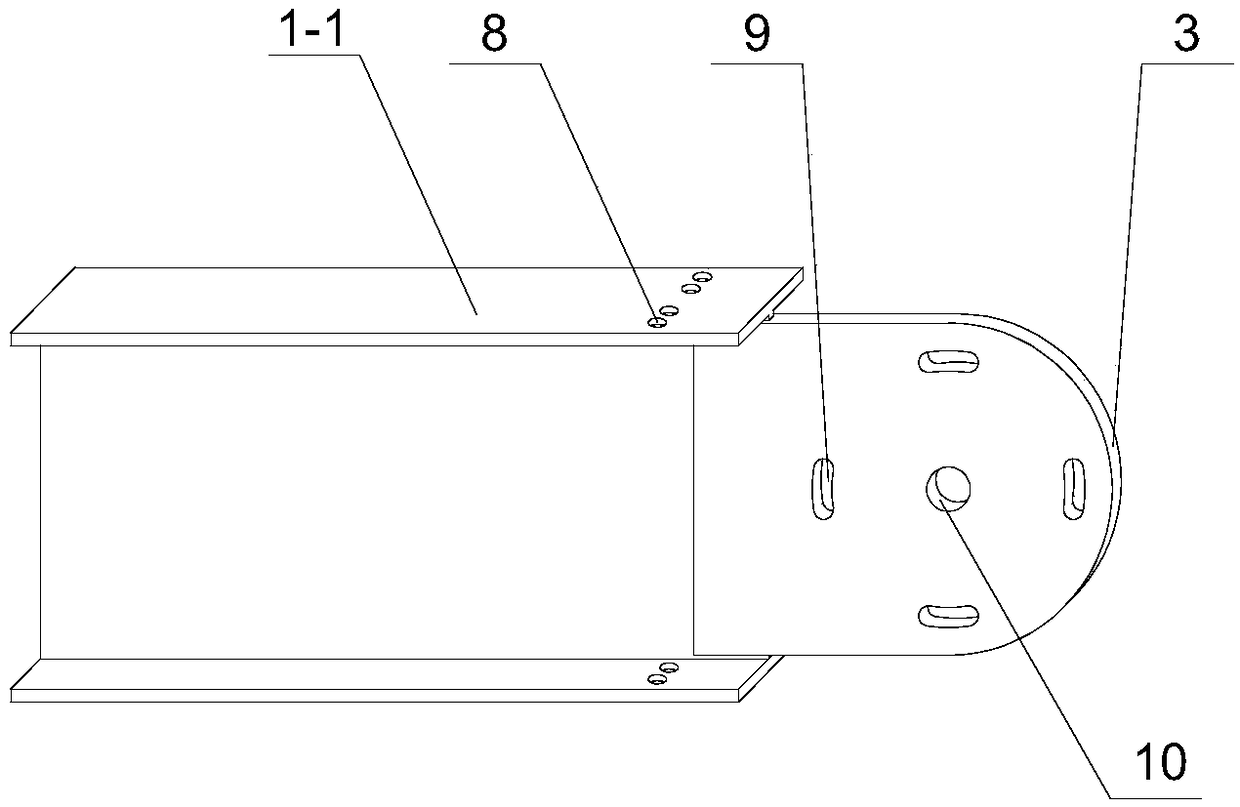

[0013] The present invention is a repairable plastic hinge with self-consumption energy, which includes three parts: a fixed unit, a rotating unit, and a connecting energy-consuming unit. Connecting bolt hole 8, double connecting plate rotating bolt hole 11, double connecting plate fixing bolt hole 12; the rotating unit is composed of steel beam 1-1, single connecting plate 3, steel beam connecting bolt hole 8, oval bolt hole 9, single The connecting plate is composed of rotating bolt holes 10; the connecting energy-consuming unit is composed of high-strength connecting bolts 2, single connecting plates 3, double connecting plates 4, fixed loading bolts 5, rotating loading bolts 6, and fixed energy-dissipating steel sheets 7; In the unit, the right beam end of the shaped steel beam 1-2 of the fixed unit is welded to the column of the structure, and the double connecting plates are respectively welded and connected to both sides of the left beam end of the shaped steel beam 1-2;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com