A calculating method for determining the interfacial rigidity of cylinders

A calculation method and technology of interface stiffness, applied in calculation, design optimization/simulation, special data processing applications, etc., can solve problems such as large calculation error, complex finite element meshing, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

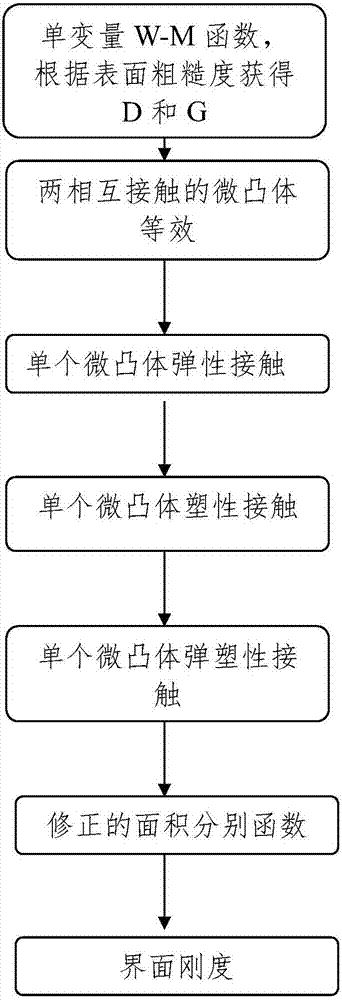

[0037] Aiming at the requirement of high-precision mechanical interface contact characteristic analysis, the present invention provides a calculation method for determining the rigidity of the cylindrical interface considering the change of material hardness with the loading depth, which is obtained according to the following steps, see figure 1 The flowchart shown:

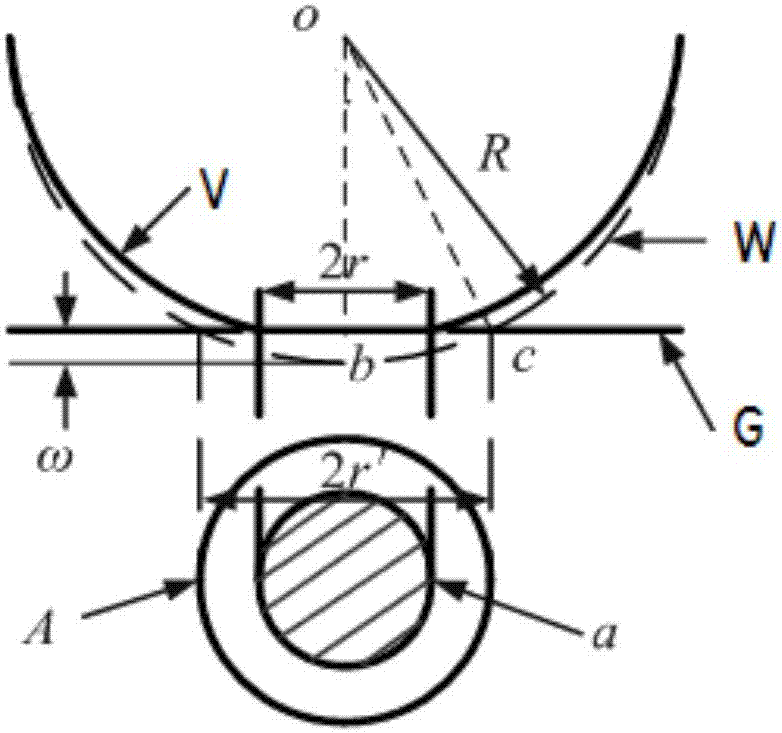

[0038] 1). With the help of the Weierstrass-Mandelbrot (W-M) function that can be used to describe the rough fractal properties of metal surfaces, According to this formula, the amount of deformation of the asperity represented by the area a and the radius of curvature at the top can be expressed as ω=G D-1 a 1-0.5D and R=π -1 G 1-D a 0.5D ; Among them, the fractal dimension of the rough surface represents the high-frequency components in the surface topography, and the range is 1a Related, according to D=1.54 / R a 0.042 Obtained, G is the fractal roughness of the rough surface, indicating the magnitude of ...

Embodiment 2

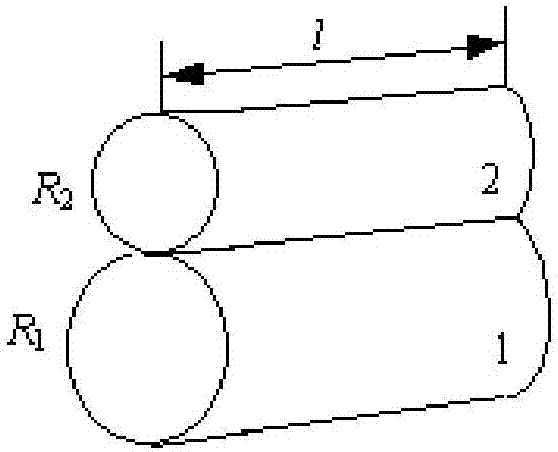

[0050] In order to verify the method of the present invention, now with Figure 5 The cylindrical junction of the combined specimens, both of which are 45 steel, is the verification object. The outer cuboid 1 is 100mm long, 72mm wide, and 84mm high; the inner cylinder 2 has a diameter of 50mm and a length of 150mm. Their materials are the same, and the specific parameters are shown in Table 1.

[0051] Table 1 Test material parameters

[0052]

[0053] According to the computing method described in embodiment 1, calculate and obtain the stiffness formula K on the total interface in step 7 n The determination of other relevant parameters in is as follows:

[0054] (1) According to step 1), D is the fractal dimension, which can be based on the relationship with surface roughness D=1.54 / R a 0.042 get, R a is the surface roughness, where the surface roughness measured by a roughness measuring instrument is 6.2, so D is 1.426.

[0055] (2) According to step 1), G is the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com