Process data optimization method of shell-shaped dental appliance making process based on hot-pressing film molding technology

A technology of process data and manufacturing process, which is applied in the fields of dentistry, electrical digital data processing, design optimization/simulation, etc. It can solve the problems that the actual applied force of the appliance does not match the designed applied force, and the orthodontic effect cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following detailed description refers to the accompanying drawings which form a part of this specification. The exemplary embodiments mentioned in the specification and drawings are only for the purpose of illustration, and are not intended to limit the scope of protection of the present application. Under the inspiration of this application, those skilled in the art can understand that many other implementations can be adopted, and various changes can be made to the described implementations without departing from the gist and protection scope of this application. It should be understood that the various aspects of the application described and illustrated herein can be arranged, replaced, combined, separated and designed in many different configurations, all of which are within the scope of the application.

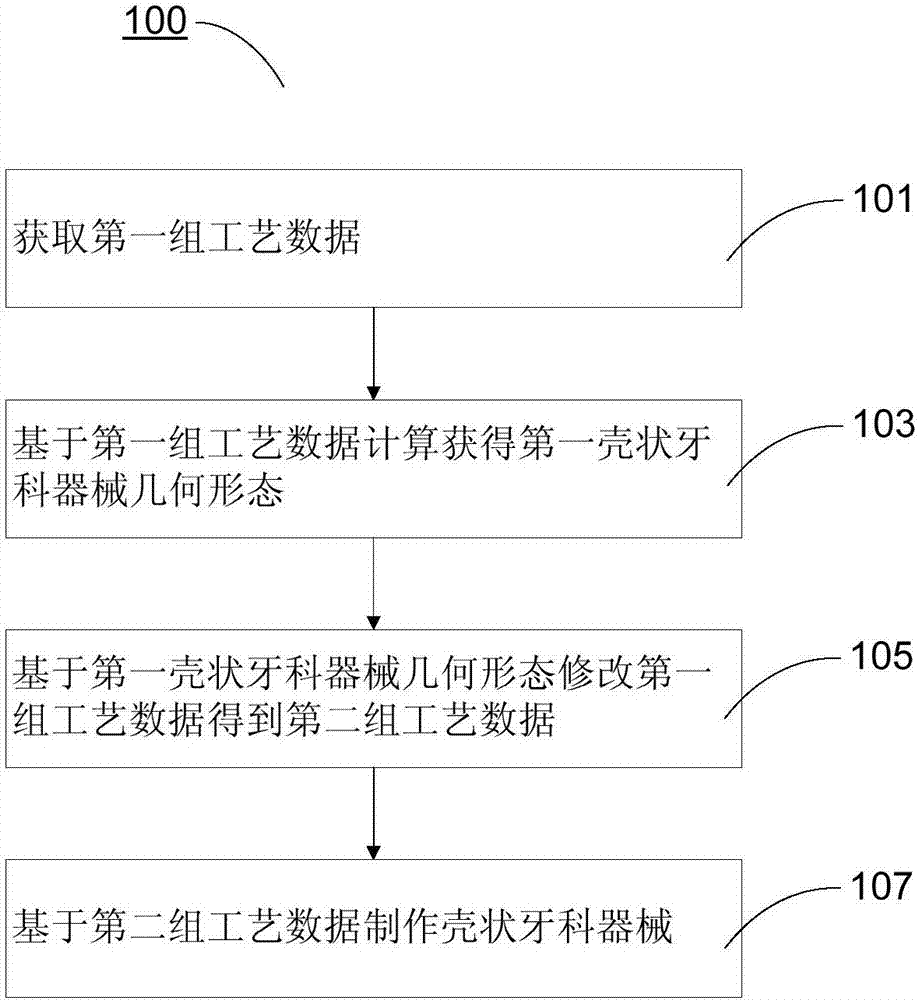

[0024] Please refer to figure 1 , a schematic flow chart of a process data optimization method 100 for a manufacturing process of a shell-shaped dental inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com