Thin-wall pressurization structure elastic-plastic deformation experimental study device

An elasto-plastic deformation and experimental research technology, which is applied in the direction of using repetitive force/pulsation force to test the strength of materials, etc., can solve the problems of high device cost, poor operation convenience, and inability to meet the pressure regulation accuracy of the manual pressure regulating system. The effect of convenient pressing process, reducing development cost, and ensuring experimental precision and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

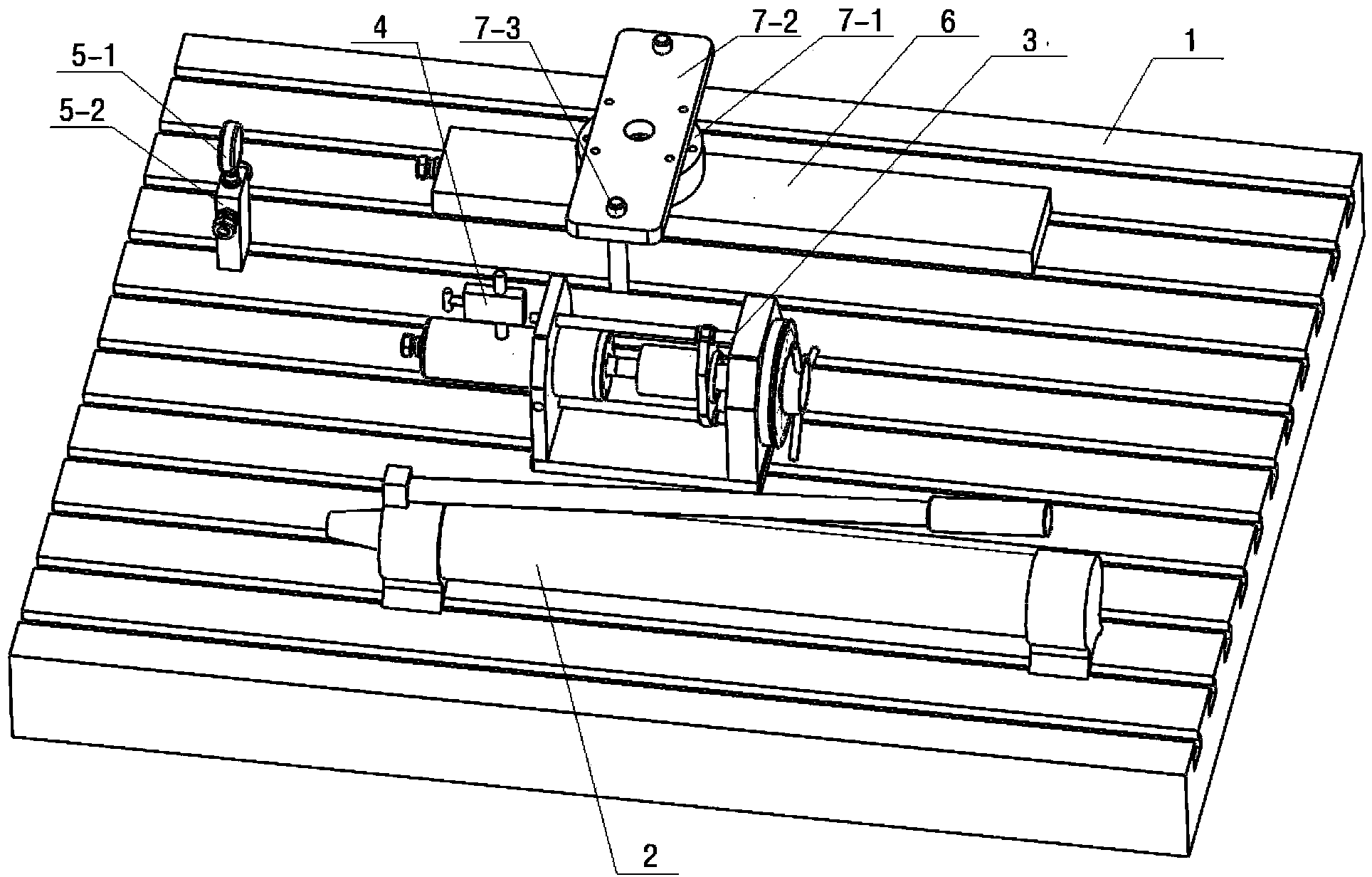

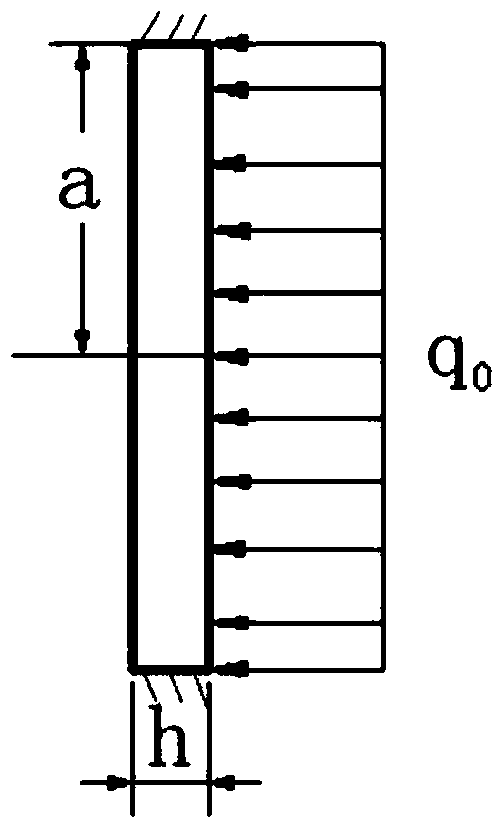

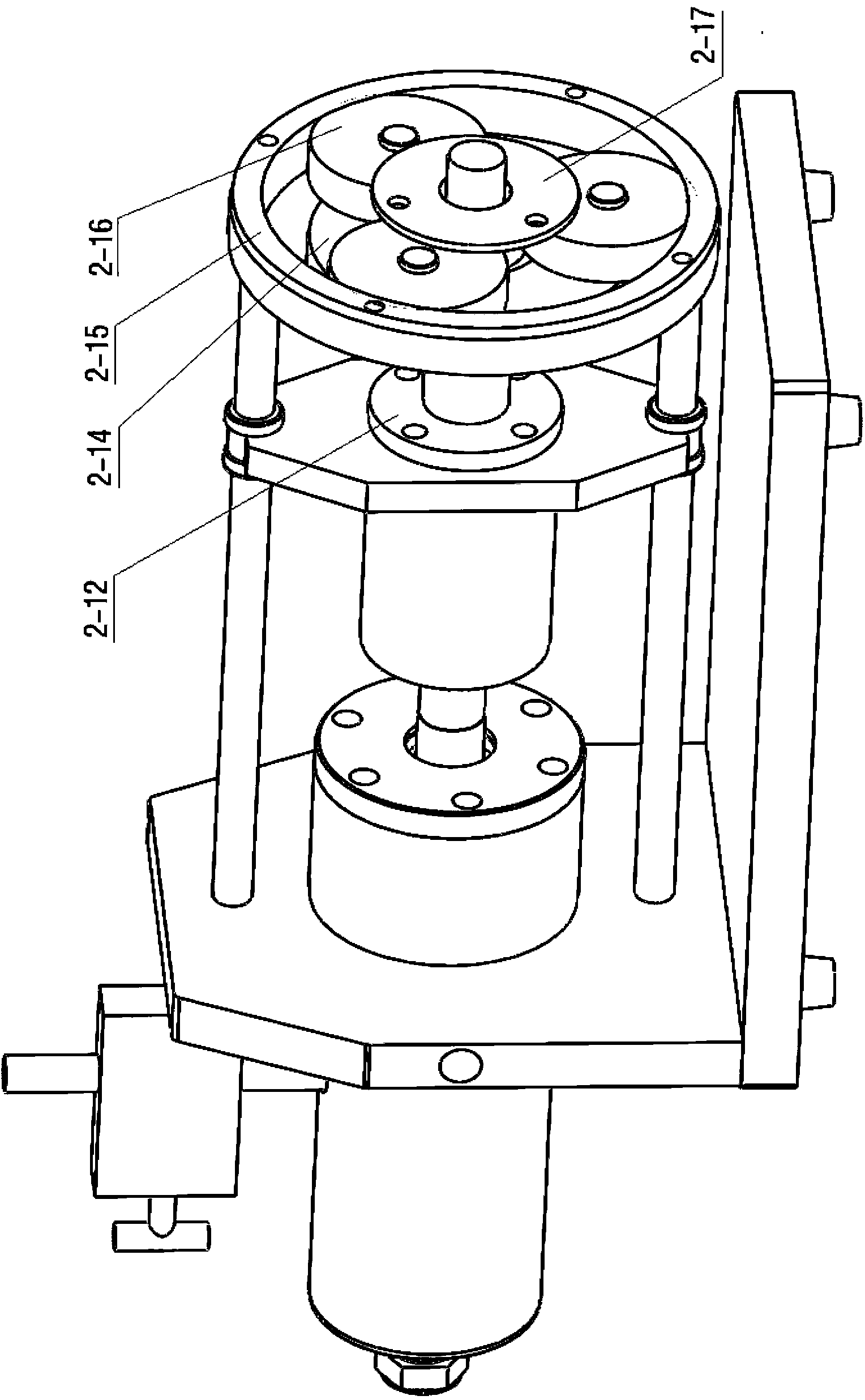

[0026] combine Figure 1 to Figure 8 , an experimental research device for elastoplastic deformation of a thin-walled pressurized structure, consisting of an oil injection module, a plunger precision pressurized pump 3, a pressure gauge 5-1, an experimental test piece 6, a micro-deformation test instrument and a pressure loading system, the described The oil injection module, the plunger precision pressurized pump 3, the experimental test piece 6 and the micro-deformation testing instrument are fixed on the high-rigidity cast iron test bench 1 in an adjustable manner. The whole part of the experimental research device is fixed or placed on a high-rigidity cast iron test bench, and the micro-deformation test instrument needs to be fixed on the test bench through a high-rigidity bracket to ensure the accuracy and scientificity of the entire experimental test results. The deformation of the thin-walled pressurized structure of the experimental structure 6 is on the order of micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com