Groove-shaped steel plate shear wall with inbuilt round reinforcing cages and externally pasted steel plate supports and construction method

A technology for supporting steel plates and round steel bars, applied in the direction of walls, building components, earthquake resistance, etc., can solve problems such as double steel plate combined shear walls, avoid adverse effects, large lateral stiffness and bearing capacity, and improve stable bearing capacity. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

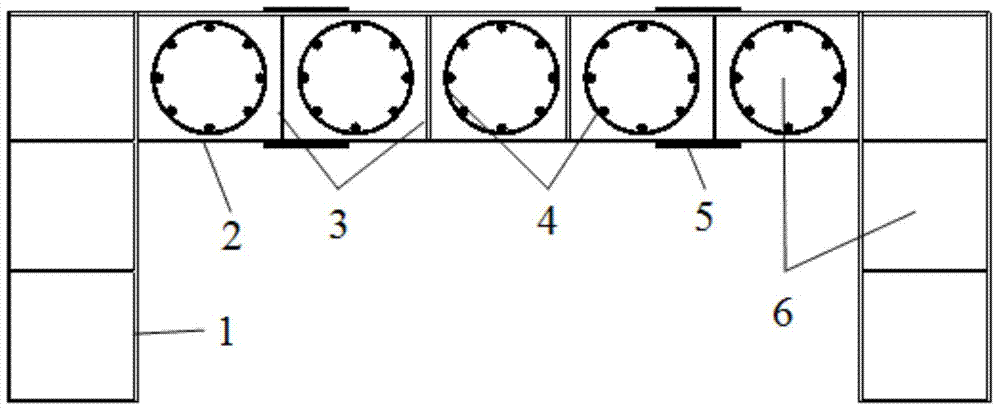

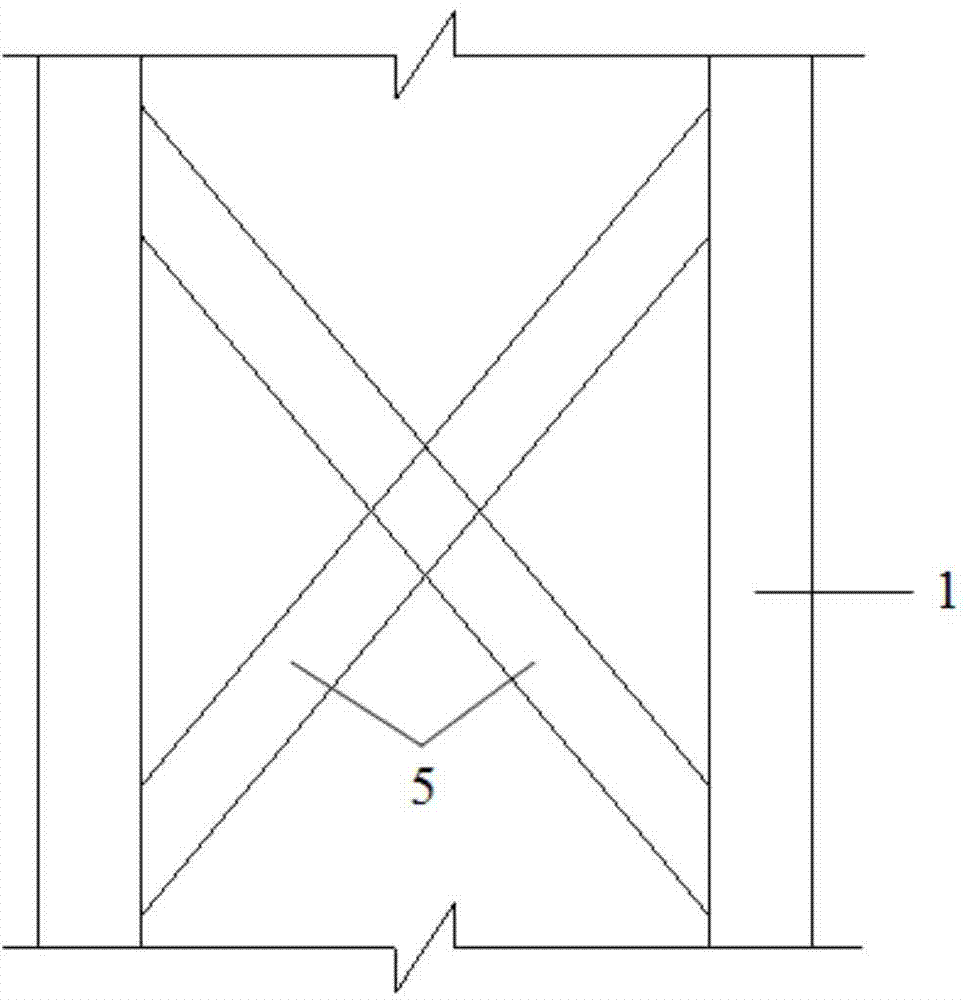

[0028] Such as figure 1 As shown, the steel plate shear wall supported by the steel plate supported by the round reinforcement cage inside the trough includes the flange multi-cavity steel pipe 1, the outer steel plate 2 of the web plate, the compartment partition 3, the round reinforcement cage 4, the steel plate support 5 and poured in Concrete in flange and web walls6. It adapts to the arrangement of shear walls in the building structure, and at the same time gives full play to the role of multiple anti-seismic defense lines.

[0029] In this embodiment, the trough-shaped built-in circular reinforcement cage and the external steel plate supporting the steel plate shear wall can be made as follows:

[0030] 1) According to the thickness of the wall, the outer steel plate 2 of the web is positioned, and welded on the inner side with the partition plate 3 of the web cavity.

[0031] 2) Put the round reinforcement cage 4 into the welded web steel structure and position it;

...

Embodiment 2

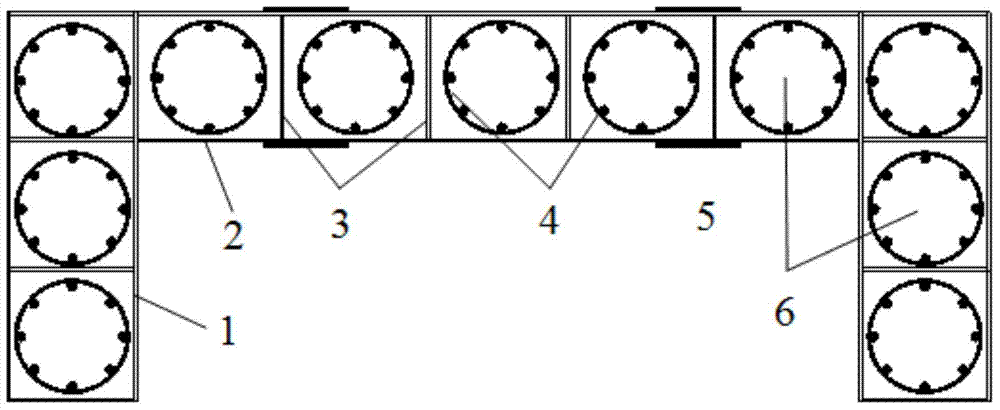

[0037] Such as figure 2 As shown, the steel plate shear wall supported by the steel plate supported by the round reinforcement cage inside the trough includes the flange multi-cavity steel pipe 1, the outer steel plate 2 of the web plate, the compartment partition 3, the round reinforcement cage 4, the steel plate support 5 and poured in Concrete in flange and web walls6. It adapts to the arrangement of shear walls in the building structure, and at the same time gives full play to the role of multiple anti-seismic defense lines.

[0038] In this embodiment, the trough-shaped built-in circular reinforcement cage and the external steel plate supporting the steel plate shear wall can be made as follows:

[0039] 1) According to the thickness of the wall, the outer steel plate 2 of the web is positioned, and welded on the inner side with the partition plate 3 of the web cavity.

[0040] 2) Put the round reinforcement cage 4 into the welded web steel structure and position it; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com