A double-layer steel plate composite shear wall with horizontal open-hole corrugated web

A combination of shear wall and steel plate shear wall technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of difficult transportation, etc., to improve the stable bearing capacity under shear, easy to process and manufacture, and strengthen the bonding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the embodiment of this patent is described in detail.

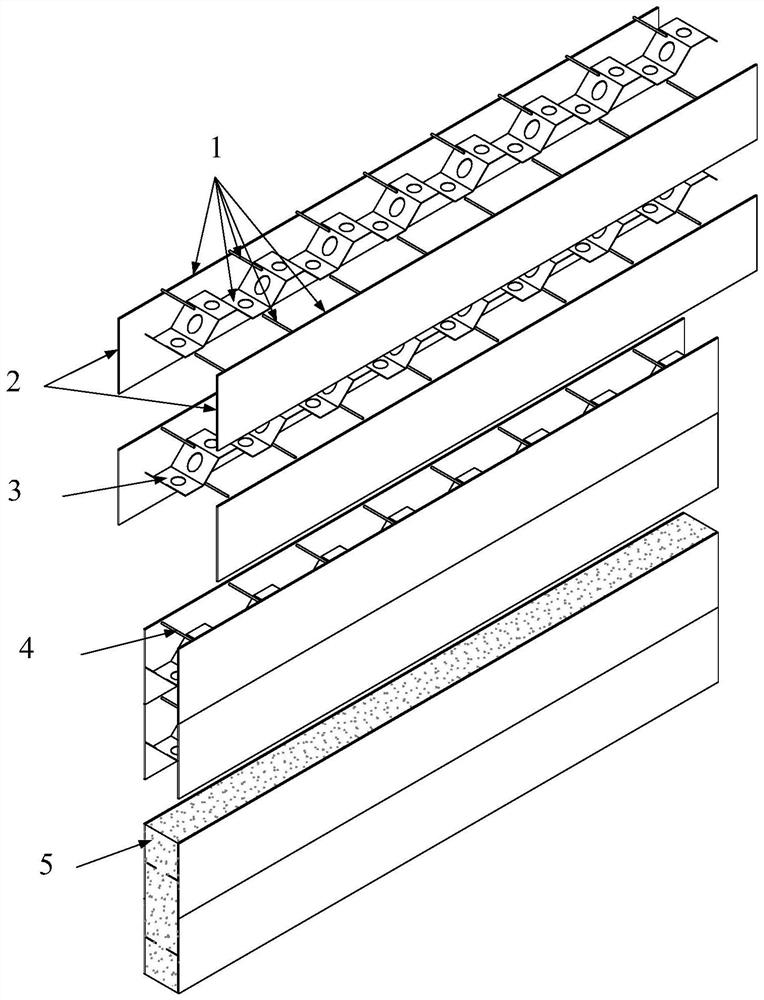

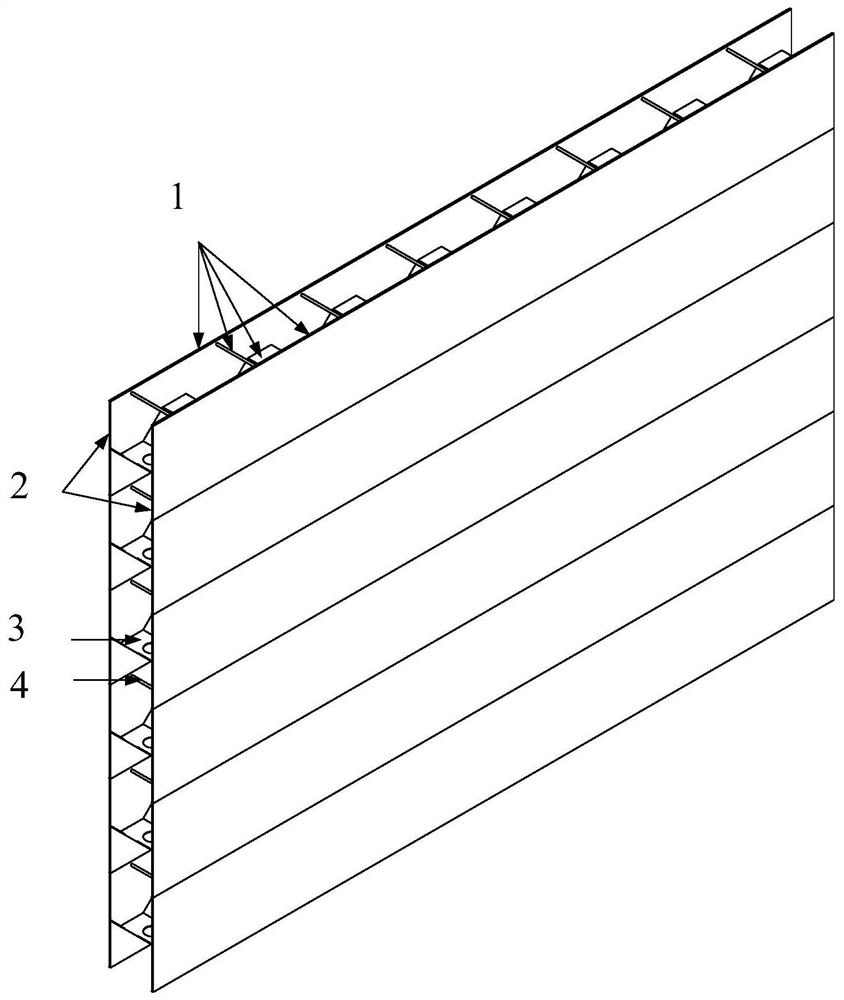

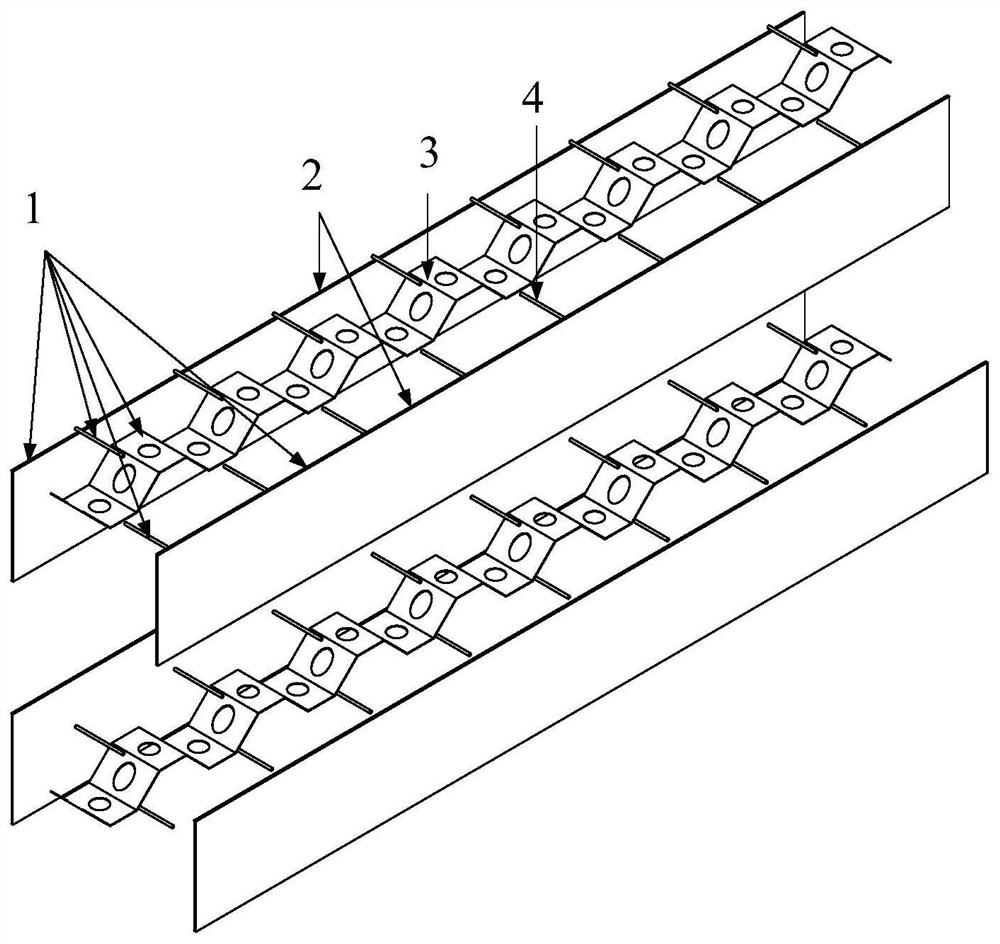

[0023] Such as Figure 1~6 As shown, a double-layer steel plate composite shear wall with a horizontal opening corrugated web includes the following components.

[0024] 1——steel plate shear wall unit;

[0025] 2 - Outer steel plate;

[0026] 3——Open corrugated web;

[0027] 4 - tie rod;

[0028] 5 - Concrete.

[0029] Such as Figure 1~4 As shown, the device is welded by several steel plate shear wall units 1 to form a double-layer steel plate shear wall, and then concrete 5 is poured between the steel plates to form a double-layer steel plate composite shear wall with a horizontal open hole corrugated web; The steel plate shear wall unit 1 described above is composed of two outer steel plates 2, a corrugated web with holes 3 and a tie rod 4; At the trough of the trough, tie the two steel plates at the front and back; each steel plate shear wall unit 1 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com