Acoustic emission inspection based research method for expanding characteristics of fatigue cracks of magnesium alloy stir-friction welding head

A fatigue crack propagation and friction stir welding technology, which is used in material analysis, strength characteristics, and measuring devices using sonic emission technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

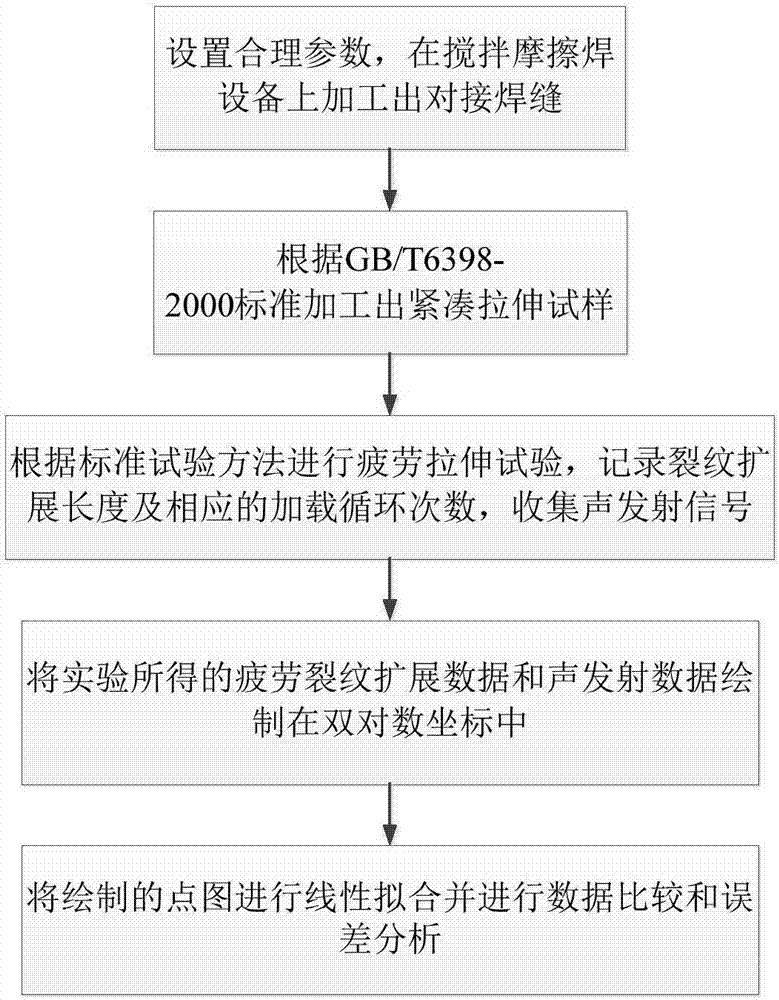

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] The research method of fatigue crack growth characteristics of magnesium alloy friction stir joint based on acoustic emission detection includes the following steps:

[0021] First, set the friction stir welding parameters, and process a 5mm thick AZ31B magnesium alloy butt weld on the friction stir welding machine. The equipment model of the friction stir welding machine is FSW-LM-AM16-2D. The length of the stirring needle is 4.85mm, the diameter of the stirring needle is 5mm, the rotation speed of the spindle is 1200r / min, and the welding speed is 300mm / min;

[0022] Second, according to the GB / T6398-2000 standard, three sets of compact tensile samples after friction stir welding of AZ31B magnesium alloy were processed. and back side (10mm from the center of the weld). The thickness of the sample is B=5mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com