Numerical simulation method for rolling process deformation of continuous variable convexity roller of wide and thick plate product

A rolling process, numerical simulation technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the gap, can not accurately describe the deformation process of continuous variable crown roll, continuous variable crown roll It is not a problem of straightness, etc., to achieve the effect of improving lifespan, low cost, good accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are specific examples of the present invention, further describing the technical solutions of the present invention, but the protection scope of the present invention is not limited to these examples. All changes or equivalent substitutions that do not depart from the concept of the present invention are included in the protection scope of the present invention.

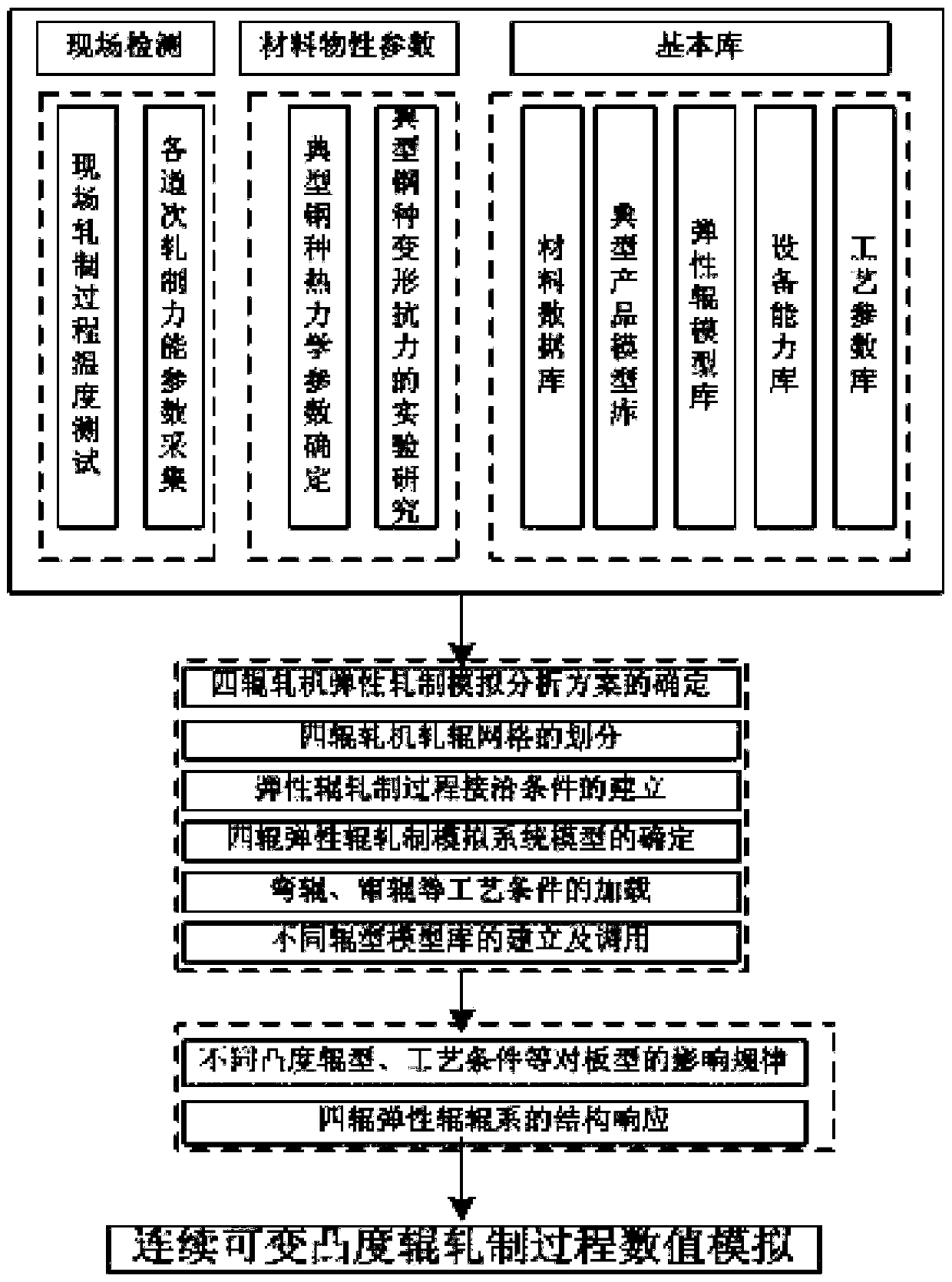

[0038] A numerical simulation method for the deformation of wide and thick plate products in the continuous variable crown roll rolling process, including the following steps:

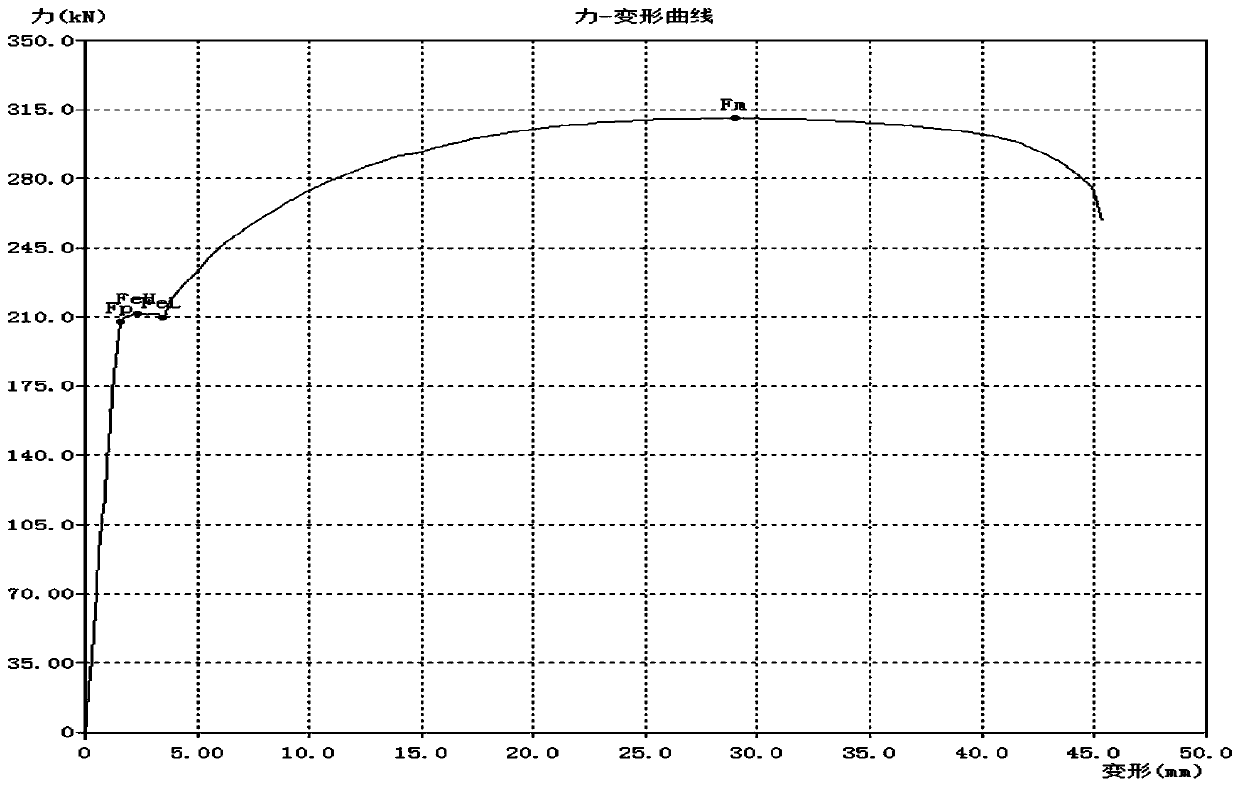

[0039] (1) Determining the deformation resistance and thermophysical parameters of typical steel types of rolled pieces;

[0040] (2) Determine the material property parameters of the continuously variable crown roll;

[0041] (3) Determine the geometric parameters of the continuously variable crown roll and the rolled piece;

[0042] (4) Establish the process parameter library of rolling mill;

[0043] (5) Using three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com