Numerical simulation method of flexible rolling and forming process of curved-surface part

A flexible rolling and forming process technology, applied in 3D modeling, image data processing, electrical digital data processing and other directions, can solve the problems of poor surface quality of formed parts, increase the amount of calculation, poor simulation accuracy, etc., to achieve low cost, High precision and efficiency, guaranteed accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the drawings and the following embodiments. It should be noted that the drawings and the following embodiments are only used to illustrate the present invention, rather than limit the present invention.

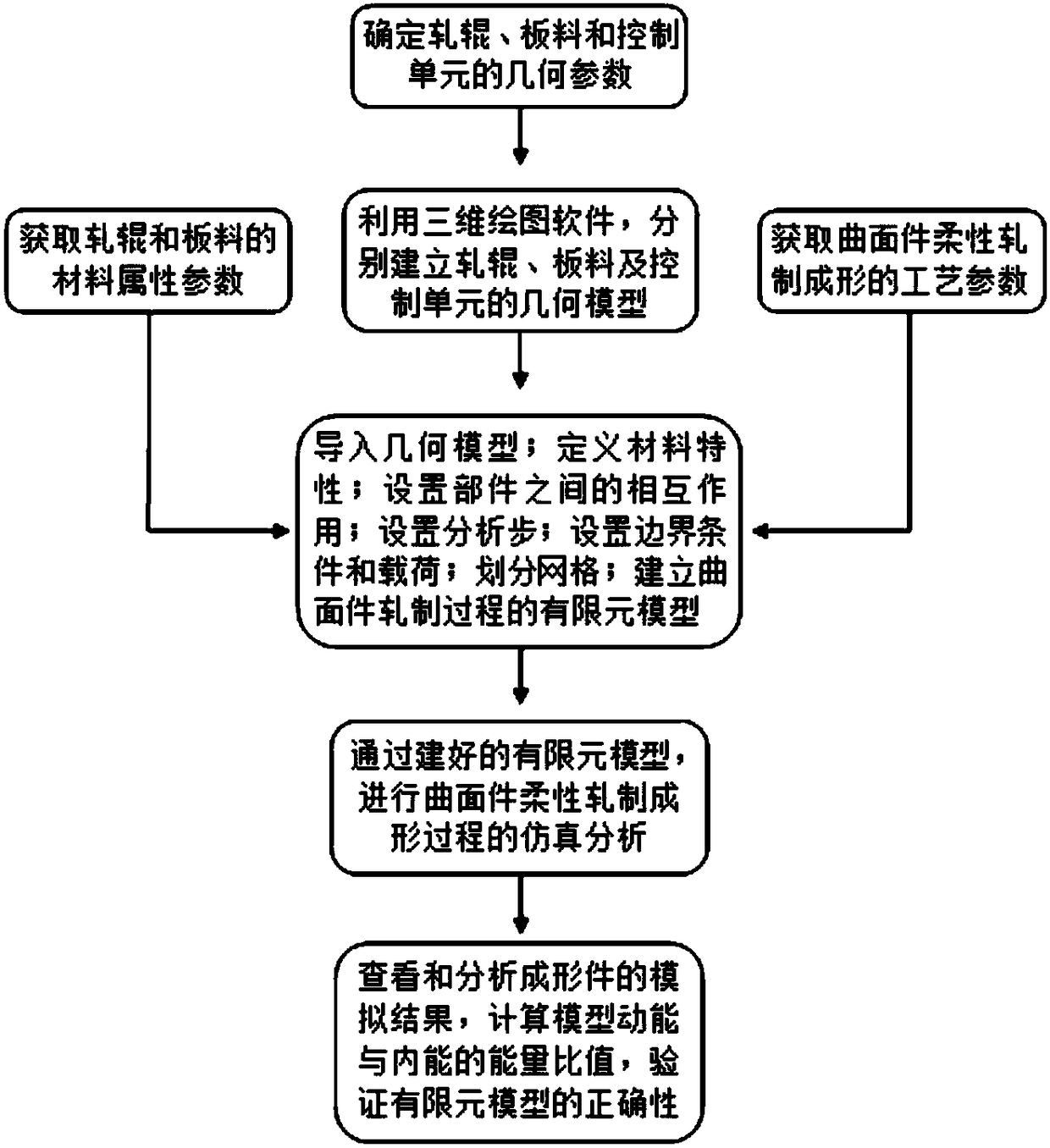

[0037] Aiming at the problem that the model simulation accuracy of the existing flexible rolling forming process of curved surface parts is not high and the simulation effect is poor, the present invention provides a numerical simulation method for the flexible rolling forming process of curved surface parts, the flow chart of which is as follows figure 1 shown. Including the following steps:

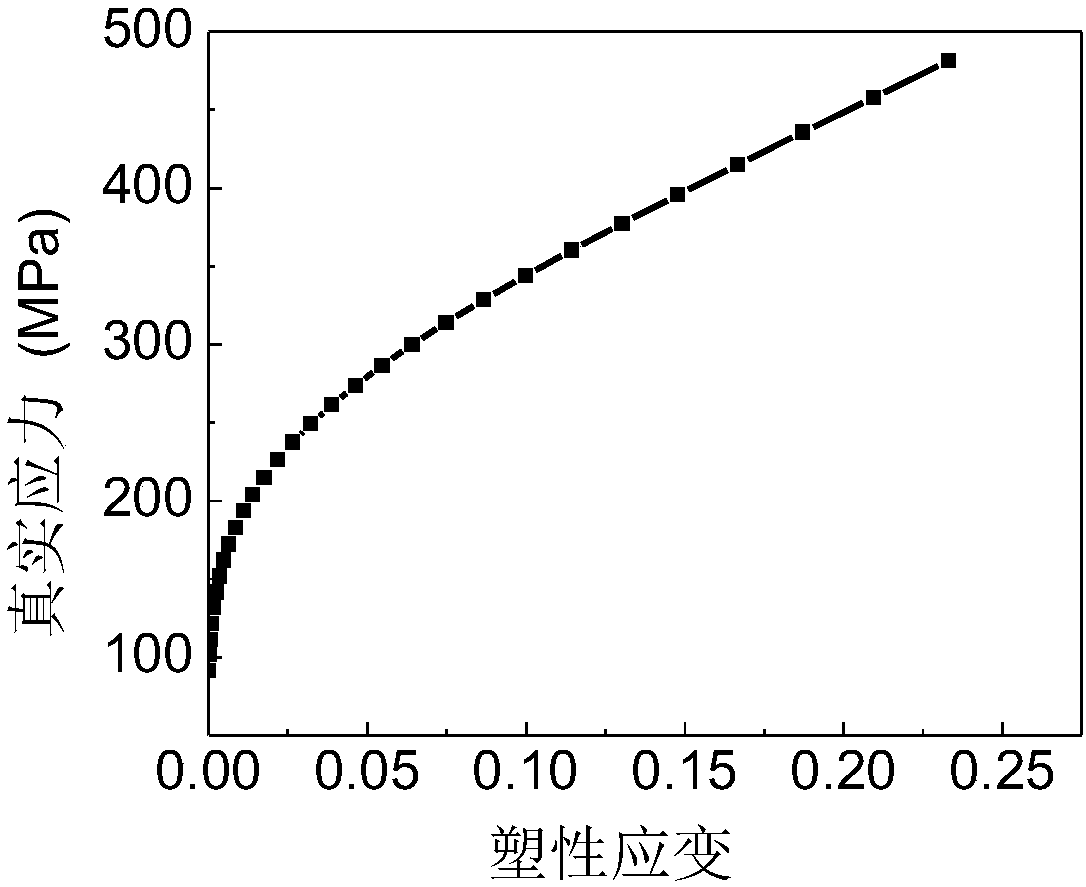

[0038] Step (1): See Table 1 for the material property parameters of rolls and sheets. In addition, with reference to the national standard GBT228-2002 for tensile specimens of metal materials, the plastic parameters of the sheet were obtained by preparing standard tensile specimens and conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com