Y-shaped blade shot blaster

A shot blasting machine and blade technology, used in rotor blades, impellers, grinding/polishing equipment, etc., can solve problems such as chatter, impact on service life, shot blasting quality, blade thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

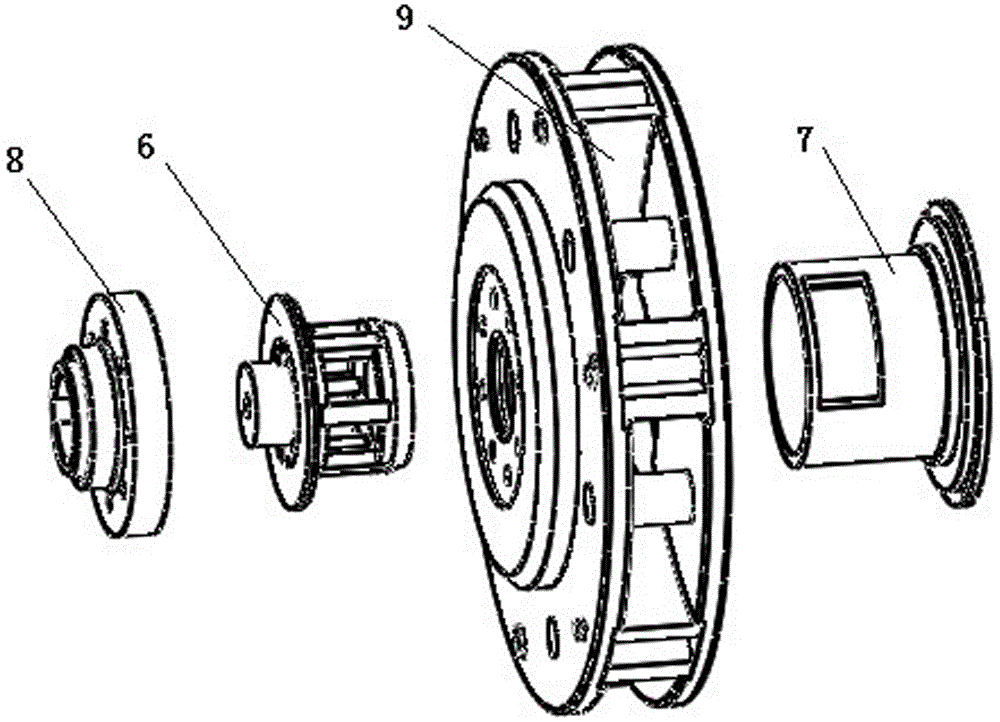

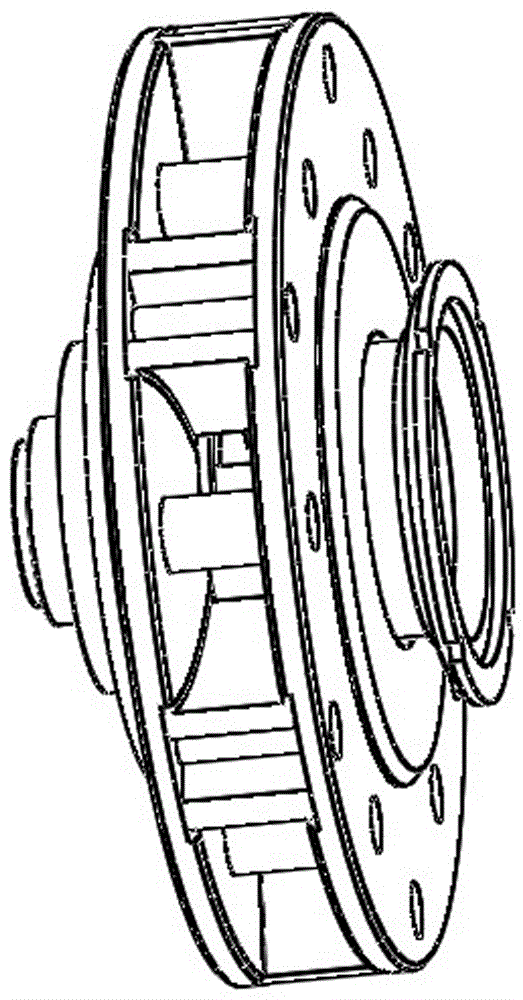

[0037] Refer to the instructions attached figure 2 with 3 As shown, the Y-blade blasting device is a typical wheel-type component, and its whole is similar to a cylinder, or an equivalent cylinder, so its end surface is essentially an axial end surface. The so-called radial is the radial under the condition of the wheel axis structure of the blade blaster as a whole.

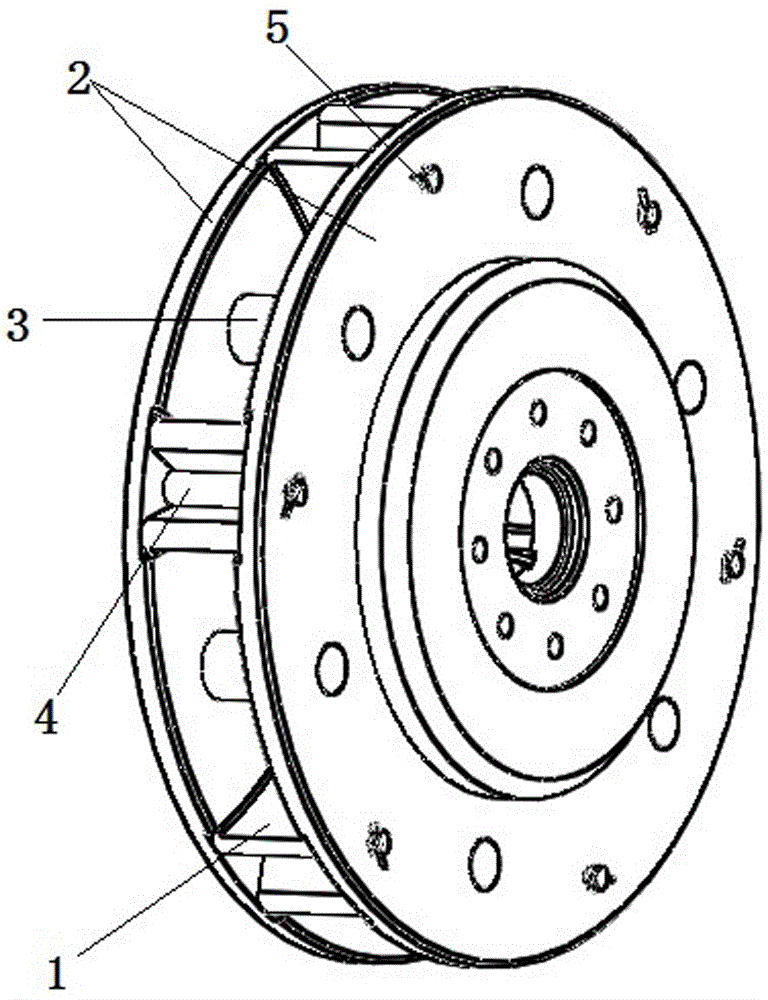

[0038] For Y-shaped blade 1, see the manual Figure 4 , The whole is a Y-shaped block with a left-right symmetrical structure, which can also be considered as a combination of a V-shaped block and a strip-shaped block, such as Figure 4 As shown, the combined sheet body 1-3 is a whole curved surface, similar to two forward curved blades.

[0039] At the same time, in the azimuth structure, based on the wheel structure, for Figure 4 In the structure shown in the structure, the base 1-2 is constituted as the end panel part of the Y-shaped block and the strip block combination. The sheet 1-3 shown in the figure is a wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com