Constraint handling device for biaxial tension and compression concrete test piece

A technology for concrete specimens and processing devices, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., which can solve the problems of uneven surface of specimens and influence on experimental results, etc., to reduce constraints, have strong operability, and prevent leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific examples.

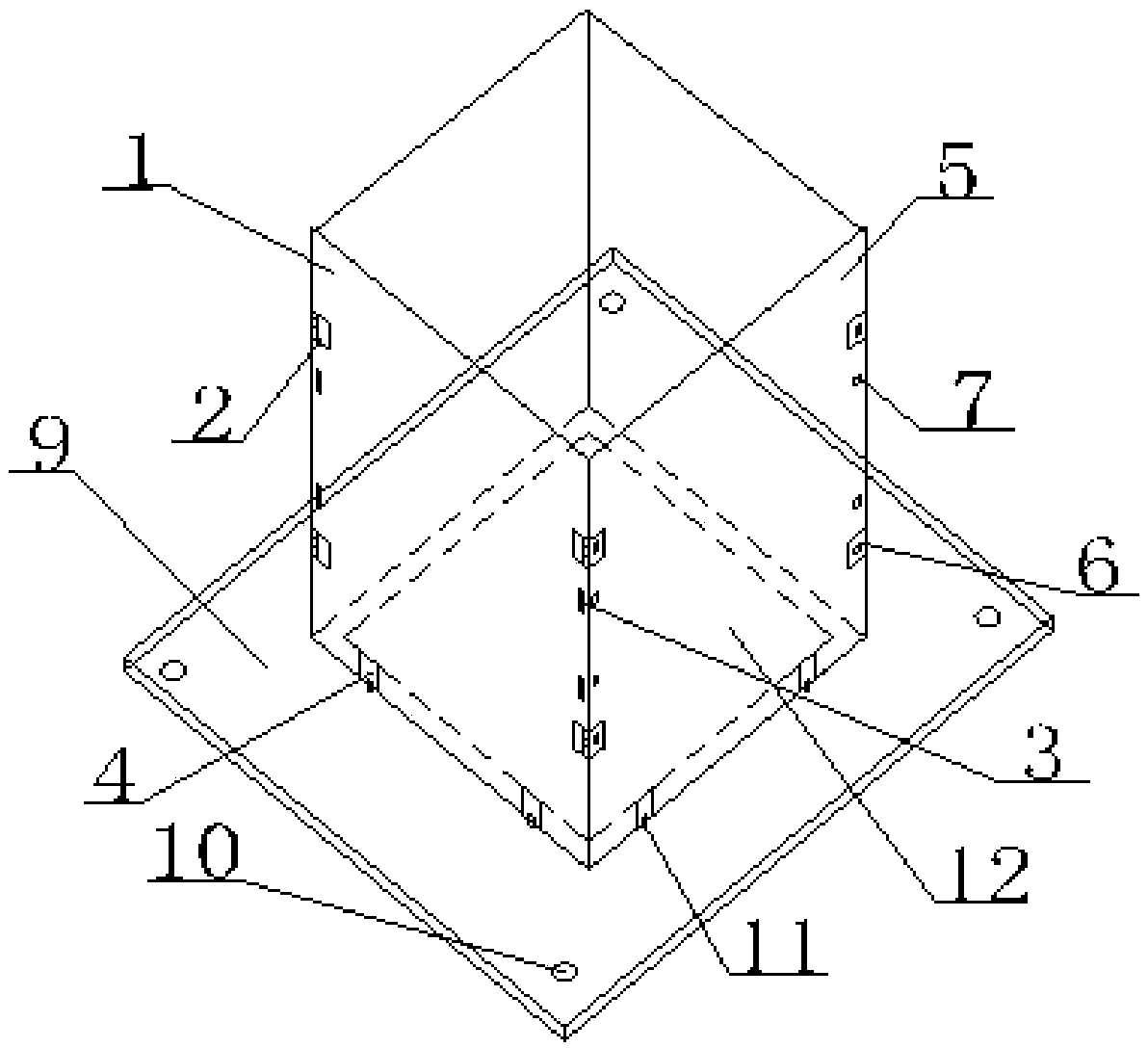

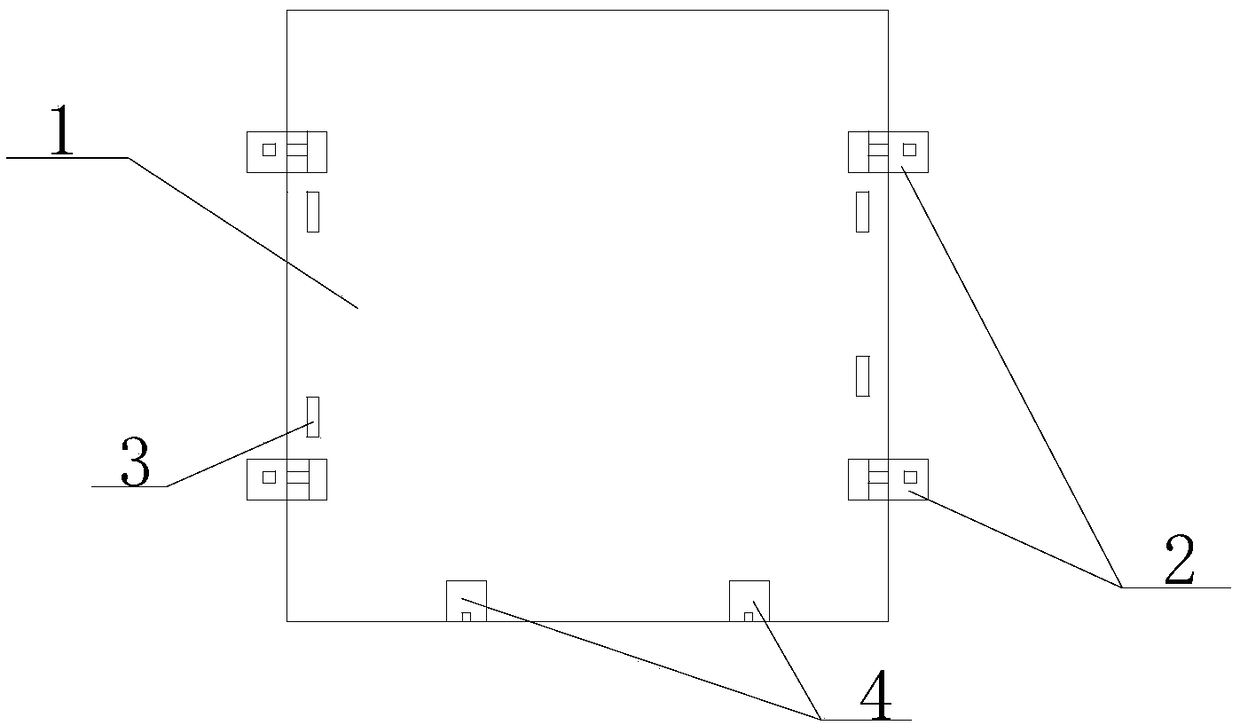

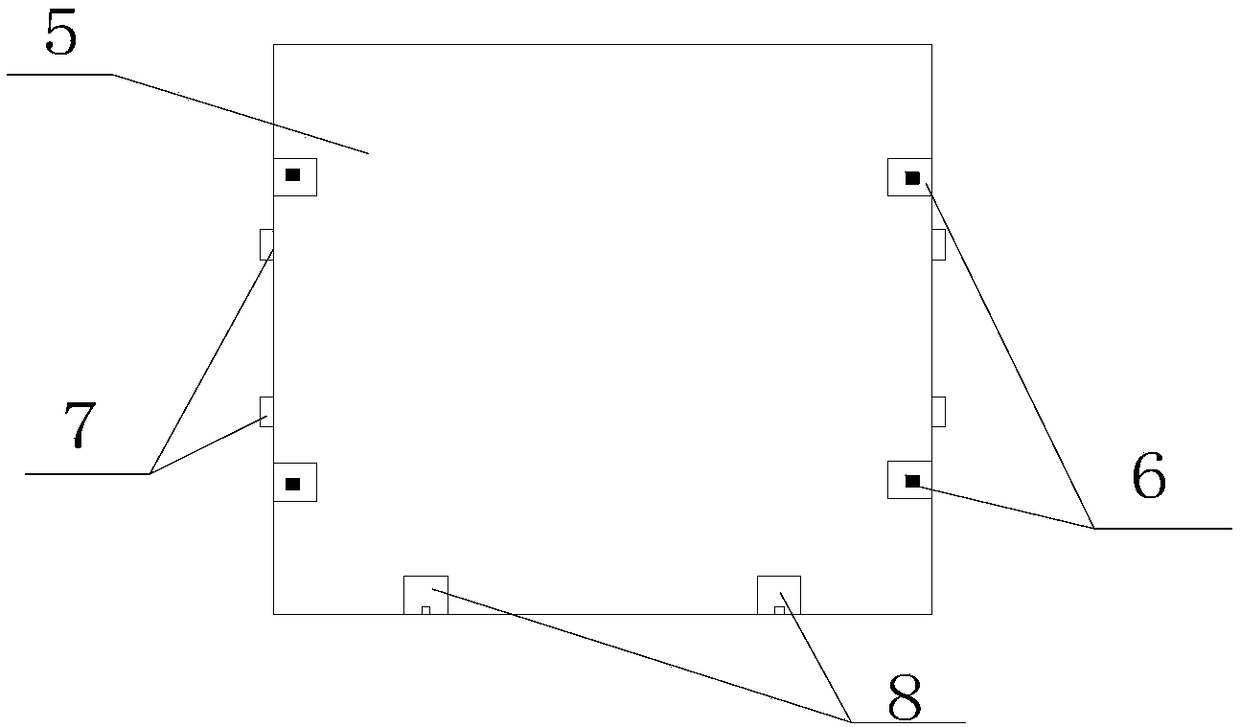

[0031] like Figure 1 to Figure 4As shown, a concrete biaxial tension-compression specimen restraint treatment device, here is a common 150mm x 150mm x 150mm cubic concrete specimen as an example for illustration. The whole device includes two first structural unit pieces 1 and two second structural unit pieces 5 in opposite positions, and a third structural unit piece 9 at the bottom. A total of five unit pieces form a rectangular outer frame of a roof. Concrete specimens are surrounded by viscous gypsum to form a protective layer, which reduces the restraint of the axial tension and axial compression loading plates on the concrete, and improves the reliability of the experimental results. The first structural unit sheet 1, the second structural unit sheet 5 and the third resultant unit sheet 9 are all transparent plastic plate structures, and the two sides of the first stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com