Anatase titanium dioxide microspheres and preparation method thereof

A titanium dioxide, anatase technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of complex semiconductor compounding steps and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of green synthetic method of anatase type nano-titanium dioxide, comprises the following steps:

[0032] (1) Add 20mL of ethanol as a solvent in the reaction kettle, add 24μL of diethylenetriamine, then add 1mL of 1-butyl-3-methylimidazolium tetrafluoroborate, and then stir on a magnetic stirrer After stirring for 10-15 minutes, add 2 mL of titanium source isopropyl titanate while stirring, continue stirring for 5-10 minutes after the addition, and finally put it in an oven at 200° C. for 24 hours.

[0033] (2) After stopping the reaction, take out the reaction solution, centrifuge to obtain the precipitate, wash the precipitate three times with ethanol, then put the precipitate in a 70°C oven and dry it for 24 hours, then grind the dried sample into powder and put it into a horse In the Furnace, the temperature was raised to 600°C at a rate of 3°C / min, and then kept for 4 hours to obtain a titanium dioxide sample.

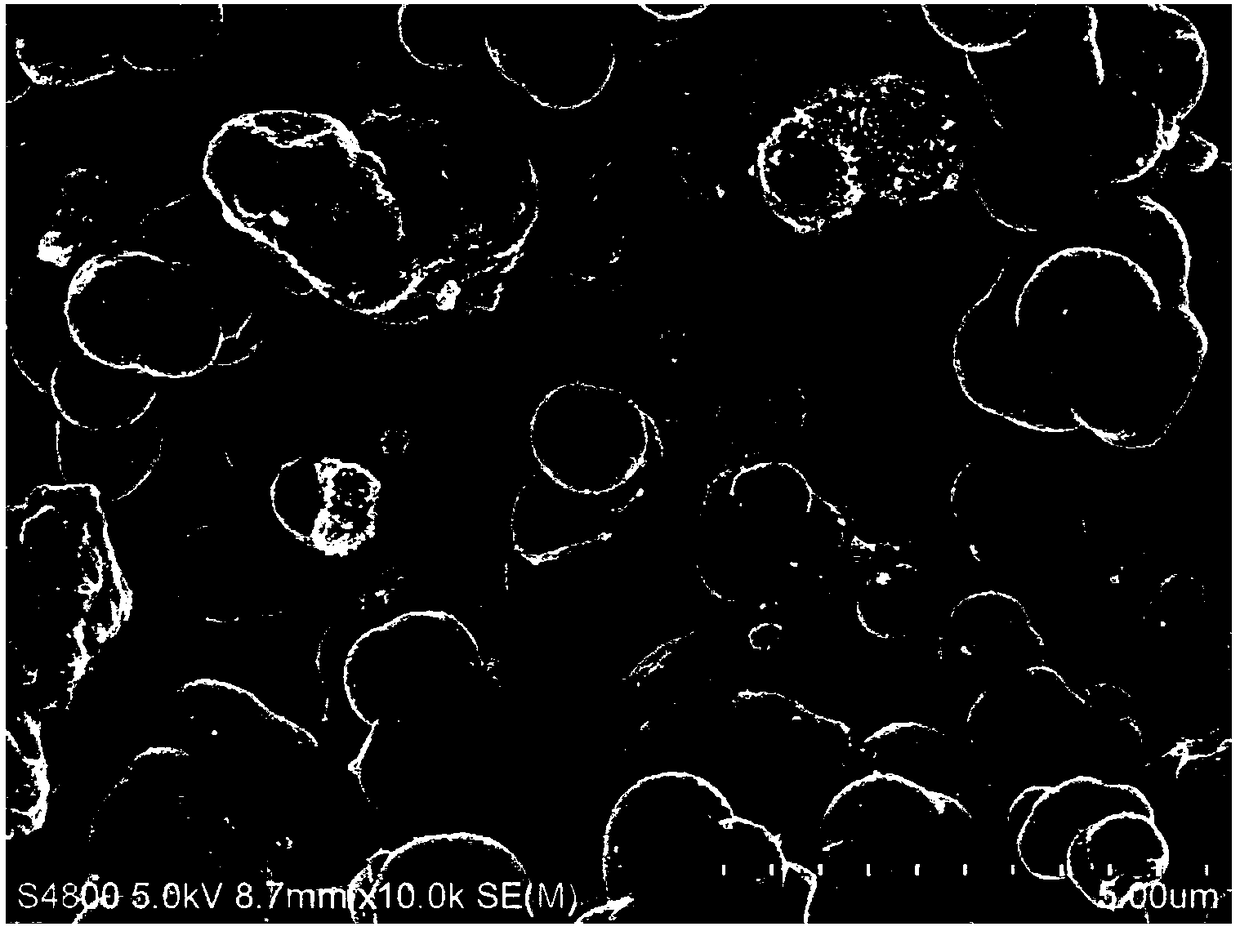

[0034] figure 1 and figure 2 TiO prepared ...

Embodiment 2

[0036] Anatase titanium dioxide microspheres were prepared by a method similar to that of Example 1, except that the amount of ethanol was 30 mL.

[0037] TiO prepared in this embodiment 2 The SEM picture is as follows image 3 As shown, the average particle size of visible microspheres is 2 μm, and the average particle size of nanoparticles is 18 nm.

Embodiment 3

[0039] Anatase titanium dioxide microspheres were prepared by a method similar to that of Example 1, except that the amount of ethanol was 35 mL.

[0040] TiO prepared in this embodiment 2 The SEM picture is as follows Figure 4 As shown, the average particle size of visible microspheres is 2 μm, and the average particle size of nanoparticles is 22 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com