Preparation method for metal-matrix composite enhanced by porous Si3N4/SiC multiphase ceramic

A technology of composite ceramics and composite materials, applied in ceramic products, applications, household appliances, etc., can solve the problems affecting the uniformity of composite materials, easy to agglomerate, etc., achieve the effect of low thermal expansion coefficient and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

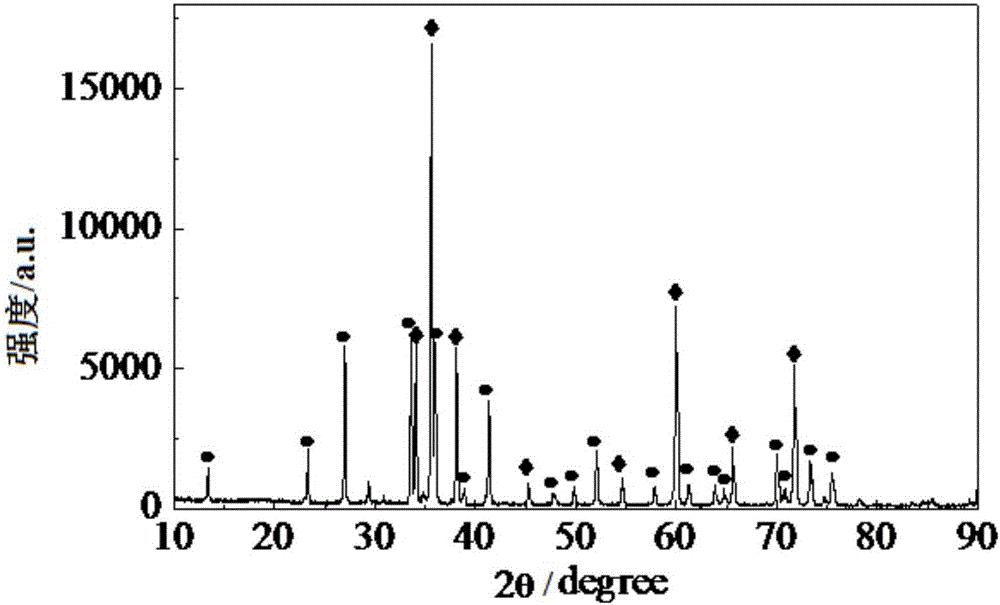

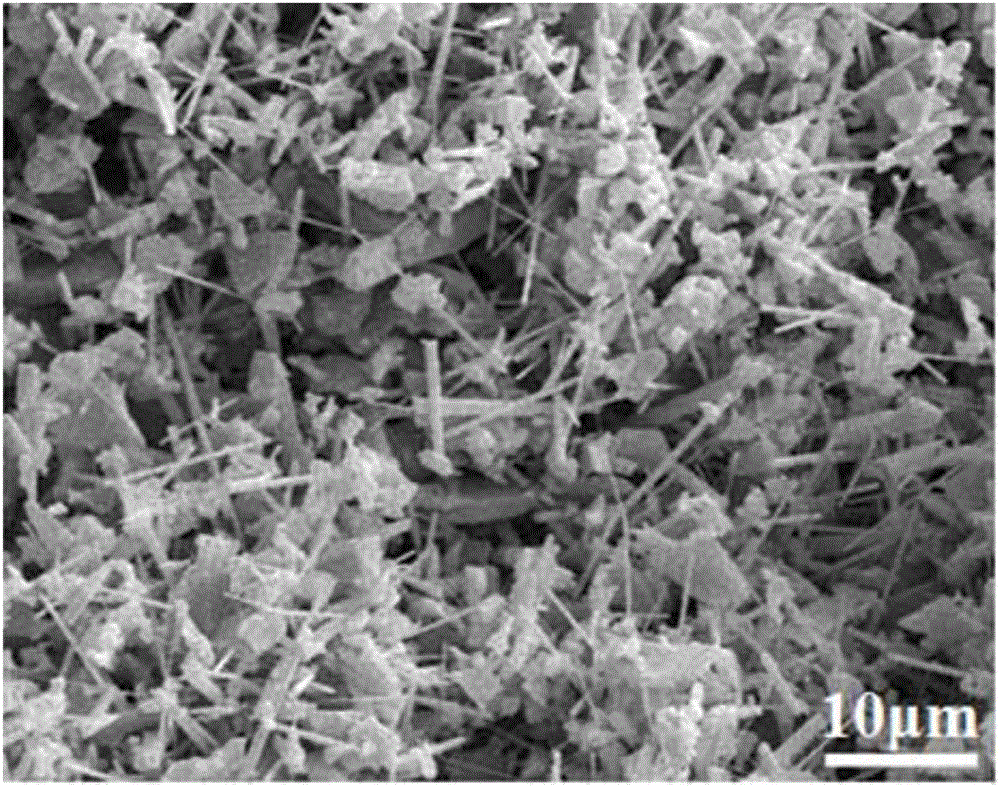

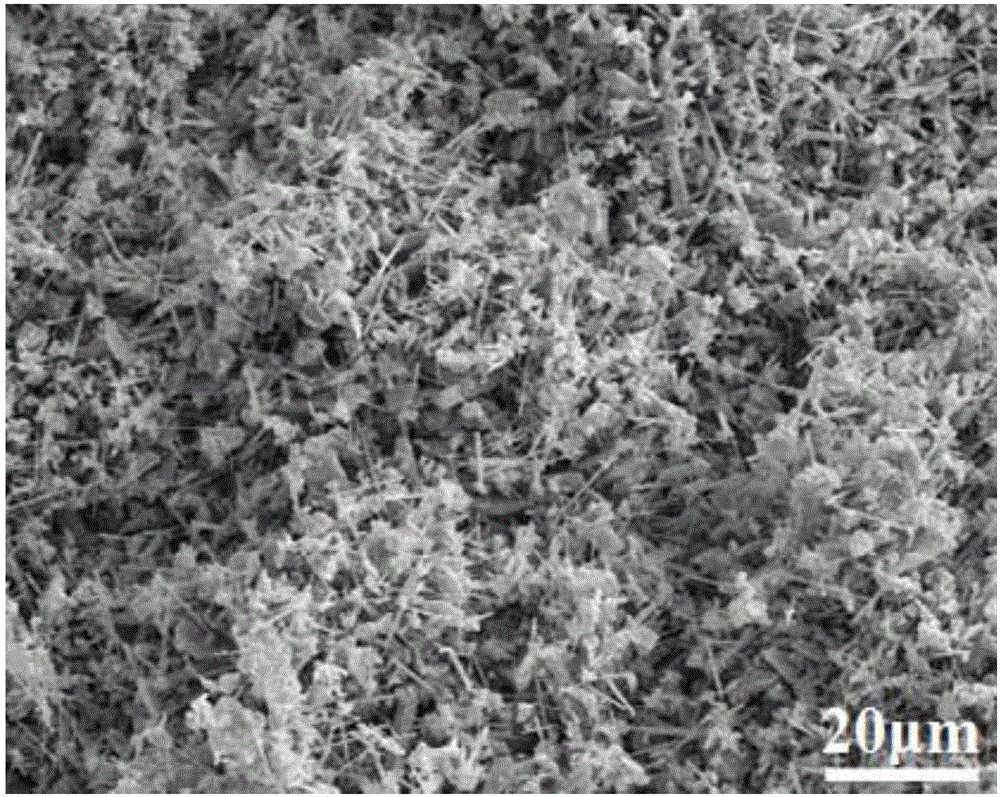

[0035] Specific embodiment one: this embodiment is a kind of porous Si 3 N 4 The preparation method of SiC multiphase ceramic reinforced metal matrix composite material is specifically carried out according to the following steps:

[0036] 1. Preparation of slurry: Mix organic solvent and water evenly to obtain a mixed solution, add ceramic powder, sintering aid, dispersant, monomer and crosslinking agent, and use Al 2 o 3 Ball milling and mixing for 11h-13h to obtain a slurry; the volume ratio of the water and the organic solution is 1:(3-5); the ceramic powder is Si 3 N 4 Mixed powder with SiC, Si 3 N 4 The mass ratio to SiC is 1:(4~6); the volume ratio of the ceramic powder to the mixed solution is 1:(1.67~10); the mass ratio of the sintering aid to the ceramic powder is 1: (23~25); The mass ratio of described dispersant and ceramic powder is 1:(200~400); The mass ratio of described monomer and ceramic powder is 1:(5~7); The mass ratio of joint agent to ceramic powde...

specific Embodiment approach 2

[0040] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the organic solvent in step 1 is isopropanol. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0041] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the sintering aid described in step one is Y 2 o 3 and Al 2 o 3 mixed powder, Y 2 o 3 and Al 2 o 3 The mass ratio is 3:2. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com