Assembled type four-combined-round-steel-pipe concrete inner support structure and manufacturing method

A technology in support structure and concrete, applied in basic structure engineering, excavation, construction, etc., can solve the problems of high cost, complicated concrete support construction, long construction period, etc., to save steel consumption, reduce concrete consumption, and ensure processing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

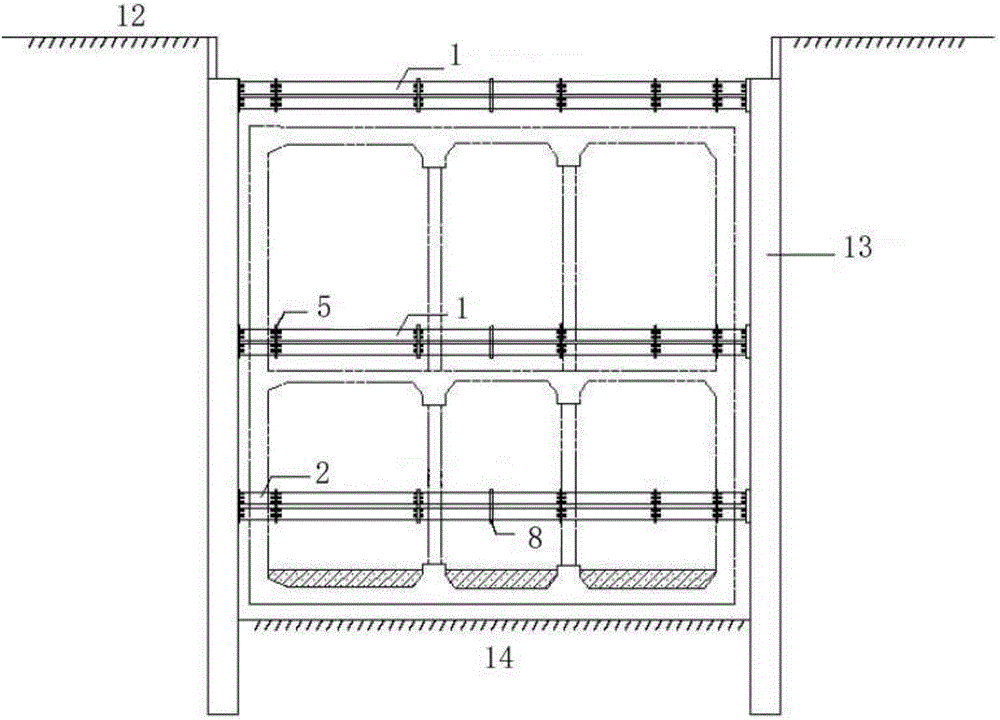

[0049] The basic idea of the invention is to form a reusable internal support system with good integrity, high rigidity and good integrity by assembling and assembling circular steel tube concrete inner support members.

[0050] The technical scheme of the present invention will be further specifically described below through an embodiment of a subway station foundation pit in conjunction with the accompanying drawings. The standard excavation width in the middle of the foundation pit is 21.7m, and the excavation width in the expanded section at the end is 25.1m. In this example, according to the width requirements of the foundation pit, the standard straight brace is divided into three specifications: 1m, 2m, 3m, and 6m, and the length of the short straight brace is less than 1m.

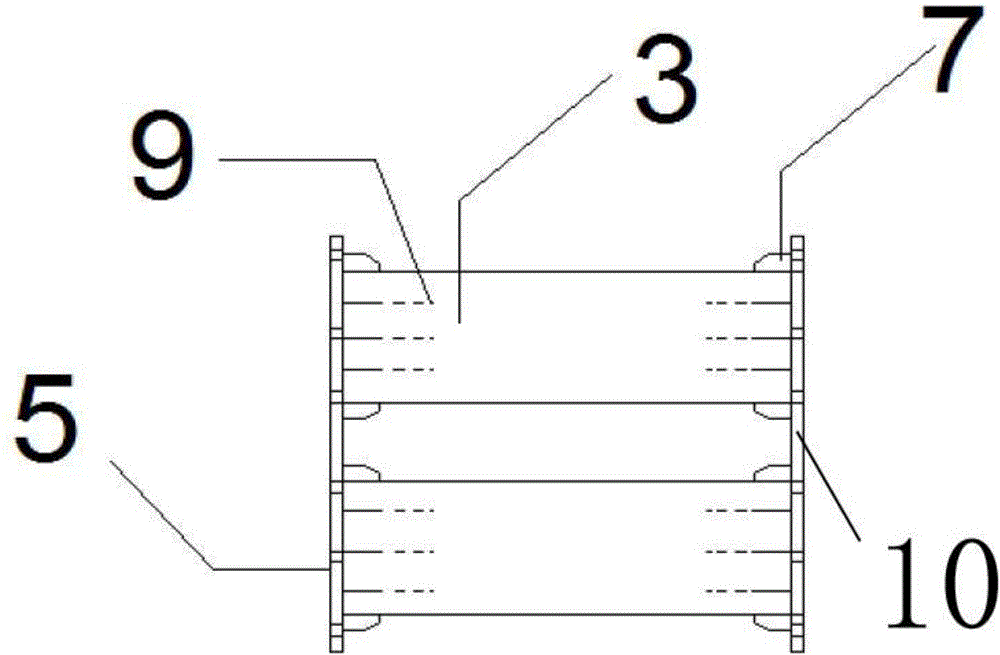

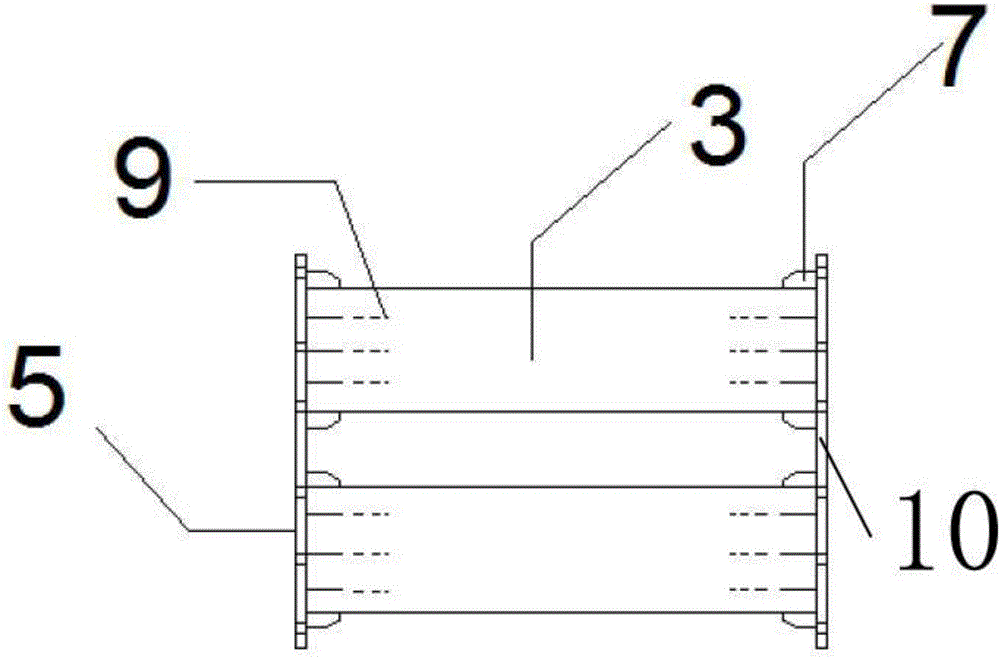

[0051] Such as Figure 1-12 Shown, the prefabricated four combined circular steel tube concrete inner support structure of the present invention. There are 4 different types of standard braces,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Section diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com